Recognizing the effect of pressure drop in your compressed air system is essential to ensure your equipment is working optimally.

Except for possibly compressed air leaks, the greatest waste of using compressed air is not addressing unnecessary pressure drops.

Pressure drop is when pressure loss occurs inside a compressed air system. This can happen at numerous points between the central compressed air tank and end-point of use applications if anything stands in the way to inhibit the flow of pressurized air.

There will always be losses in compressed air transmission as it is a natural occurrence. But the goal is to minimize it. The size of the compressed air delivery piping is often the culprit for high loss. When the piping is installed initially, it may have been sized for a particular compressed air load.

Over time, the air consumption requirements may have increased or otherwise substantially changed such that one factory area may be optimized or even oversized (which is fine) while another faces heavy pressure losses.

It is wise to audit the equipment’s compressed air consumption and relate the volume to the diameter and length of piping that supplies that piece of equipment. In these instances, it could be economical to change the piping size or add a parallel air supply line to correct the issue.

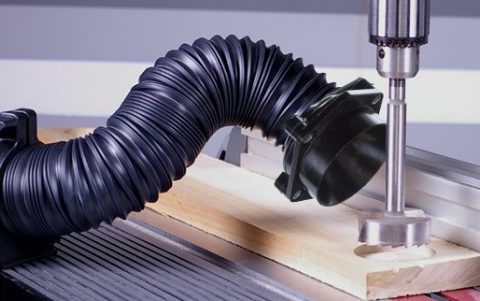

Another source of pressure loss is undersized, blocked, or worn-out fittings and under-maintained filters. These fittings and filters need to be in top working order to keep pressure loss low and keep the compressed air system clean and dry.

Leaks, of course, also cause pressure loss, and these leaks not only occur in piping but are also common in worn-out fittings and filters with auto drains that are stuck open and not corrected. Even manual valves are sometimes accidentally left open or only partially closed. These waste energy in lost air and reduce system pressure, negatively affecting equipment operation.

Please message me if you require assistance using compressed air for blow-off, moving, cooling or drying or on any questions about your compressed air system.