“What does dBA mean when someone talks about noise levels?”

Compressed air exhaust produces noise whether from cylinders, solenoid valves, or from blow off nozzles. Air conditioning and cooling technology has become more advanced as individual, industrial, and manufacturing demands have increased at the same rate. The efficiency of a type of cooler is a primary concern, but so is the noise level. Different types of air conditioners emit different noise levels and are noisier as they age. It is important to understand how noise is measured and the strategies that can be used to reduce noise in your factory environment. This article describes Occupational Safety and Health Administration (OSHA), their recommended occupational noise limits, penalties for not complying, and products that are designed to reduce noise so that the factory environment can comply with OSHA recommendations.

What is Noise and How is it Measured?

Most of us live and work in loud environments. Without proper ear protection, this can lead to profound hearing loss, which affects the quality of life of us, our friends, and our family. Noise and vibration are both fluctuations in the pressure of air (or other media) which affect the human body. Vibrations that are detected by the human ear are classified as sound. We use the term ‘noise’ to indicate unwanted sound.

The logarithmic scale that measures sound and loudness is called a decibel. Sound energy travels in waves and is measured in frequency and amplitude. The intensity of the noise emitted from air conditioning units, for example, is the force of the sound wave (amplitude) and is measured in decibels (‘dB’). The decibel scale starts 0, the softest sound a human can detect, and increases in multiples of 10 dB. Every increase of 3 dB represents a doubling of sound intensity or acoustic power. Table 1 lists the common sounds that are heard:

Table 1: Common Sounds

| Sound | dBA |

|---|---|

| Breathing | 10 |

| Normal Speaking Voice | 65 |

| Rock concert | 120 |

| Dog Barking from 4 feet | 95 |

| Passenger car at 65 mph at 25 ft | 77 |

| Vacuum Cleaner | 70 |

Noise levels is measured by a sound level meter using the decibel scale. The factors affecting the reading are:

- The distance between the meter and the source of the measured sound

- The direction the noise is facing relative to the meter

- Is it an indoor or outdoor measurement? Outdoor sound will dissipate more than indoor noise, which reverberate.

For the sound measurement to be useful, the conditions under which the reading is taken and the distance from the source must be reported.

When purchasing a new air conditioner, the decibel noise level is printed on the specifications for indoor and outdoor units. If the decibel level is not on the specification, ask the installer to provide the measurement.

What is the difference between dB and dBA?

A dB(A) measurement has been adjusted to consider the varying sensitivity of the human ear to different frequencies of sound. Therefore, low and very high frequencies are given less weight than on the standard decibel scale. Many regulatory noise limits are specified in terms of dBA, based on the belief that dBA is better correlated with the relative risk of noise-induced hearing loss.

Compared with dB, A-weighted measurements underestimate the perceived loudness, annoyance factor, and stress-inducing capability of noises with low frequency components, especially at moderate and high volumes of noise. (Richard L St Pierre Jr and Daniel J Maguire, “The Impact of A-weighting Sound Pressure Level Measurements during the Evaluation of Noise Exposure” (paper presented at NOISE-CON, Baltimore, Maryland, July 12–14, 2004).)

db-C or the C-weighting scale is sometimes used for specifying peak or impact noise levels but there is generally not much of a difference between the two.

Occupational Safety and Health Administration (OSHA) Occupational Noise Exposure

Occupational Safety and Health Administration (OSHA) is an agency of the United States Department of Labour. Congress established the agency under the Occupational Safety and Health Act, which President Richard Nixon signed on December 29th, 1970.

OSHA sets legal limits on noise exposure in the workplace. These limits are based on the time a worker spends during a weighted average over an 8-hour day. With noise, OSHA’s permissible exposure limit (PEL) is 90 dBA for all workers for an 8-hour day. The OSHA standard uses a 5-dBA exchange rate.

The potential for a sound to damage hearing is proportional to its intensity, not its loudness. That is the reason why it is misleading to rely on our subjective perception of loudness as an indication of the risk to hearing.

Noise and vibration can harm workers when they occur at high levels or continue for a long time. The greater the sound pressure a sound has, the less time it takes for damage to occur to hearing. For example, an 85-dBA sound may take up to 8 hours to cause permanent damage, while a sound at 100 dBA can damage hearing after 30 minutes. Occupational exposure limits (OELs) for various noise levels are the maximum duration of exposure permitted. Table 2 lists decibel exposure time guidelines.

Table 2: Decibel Exposure Time Guidelines with Examples

| Continuous dB | Examples | Permissible Exposed Time |

|---|---|---|

| 85 | Busy City Traffic | 8 hours |

| 88 | 4 hours | |

| 91 | 2 hours | |

| 94 | Gas powered mower,

Hair dryer |

1 hour |

| 97 | 30 minutes | |

| 100 | 15 minutes | |

| 103 | 7.5 minutes | |

| 106 | Tractor (105 dB) | < 4 minutes |

| 109 | < 2 minutes | |

| 112 | < 1 minute | |

| 115 | Leaf Blower, Rock Concert, Chainsaw | < 30 seconds |

Table 3: illustrates the comparative noise level differences by 10 decibels

| Noise Source | Decibel Level | Effect |

|---|---|---|

| Jet take-off (at 25 meters) | 150 | Eardrum rupture |

| Aircraft carrier deck | 140 | |

| Military Jet Aircraft take-off from a carrier with afterburner (50 ft) | 130 | Painful. 32 times as loud as 70 dB |

| Steel mill auto horn at 1 m; live rock music | 110 | Average human pain threshold. 16 times as loud as 70 dB |

| Power lawn mower; Bell J-2A helicopter at 100 ft | 100 | 8 times as loud as 70 dB. Serious damage possible in 8-hour exposure. |

| Motorcycle at 25 ft | 90 | 4 times as loud as 70 dB. Likely damage in 8-hour exposure. |

| Dishwasher; Average factory, car wash at 20 ft; food blender | 80 | 2 times as loud as 70 dB. Possible damage in 8-hour exposure. |

| TV audio | 70 | Upper 70s are annoying to some people |

| Conversation in a restaurant | 60 | Half as loud as 70 dB. |

| Conversation at home | 50 | One fourth as loud as 70 dB. |

| Library | 40 | One eight as loud as 70 dB. |

| Rural area | 30 | One sixteenth as loud as 70 dB |

| Whisper | 20 | |

| Breathing | 10 | Barely audible |

American Criteria

OSHA requires that workers exposed to an average of 90 decibels for eight hours wear hearing protection. Under the agency’s measurements, when the volume increases by 5 decibels, the nose doubles. As a result, the permissible exposure time is cut in half. If the levels reach 95 decibels, the maximum exposure without hearing protection is 4 hours.

The counsel for accreditation in occupational hearing conservation (CAOHC) has stricter guidelines. “Under the stricter guidelines, workers may not be exposed to 85 decibels for more than 8 hours a day without hearing protection. Several agencies have also concluded that the risk of hearing loss doubles with every 3 decibels increase, not 5.” (The New York Times, Retrieved on October 25, 2018)

Find out more about workplace safety and health topic with NIOSH.

Canadian Criteria

The criterion level, often abbreviated as Lc, is the steady noise level permitted for a full eight-hour work shift. This is 85 dB(A) in most jurisdictions, but it is 90 dB(A) in Quebec and 87 dB(A) for organizations that follow the Canadian federal noise regulations.

The exchange rate is the amount by which the permitted sound level may increase if the exposure time is halved. The allowed maximum exposure time is calculated by using an exchange rate. As the sound level increases above the criterion level, Lc, the allowed exposure time must be decreased.

Contact Canadian Centre for Occupational Health and Safefor additional information.

European Criteria

“In 2003, Directive 2003/10/EC of the European Parliament and of the Council on the minimum health and safety requirements regarding the exposure of workers to the risks arising from physical agents (noise) was adopted. This directive is to be transposed into the national legislation of all Member States before 15 February 2006 (132). The main characteristic of the new noise directive is to establish a clear and coherent prevention strategy capable of protecting the health and safety of workers exposed to noise.

Article 5(1) of the directive requires that, taking into account technical progress and the measures available to control the risk at source, ‘the risks arising from exposure to noise shall be eliminated at their source or reduced to a minimum’. In order to avoid irreversible damage to workers’ hearing, the directive foresees exposure limit values of 87 dB(A) and a peak sound pressure of 200 Pa, above which no worker may be exposed; the noise reaching the ear should, in fact, be kept below these exposure limit values. The directive also foresees upper and lower exposure action values of respectively 85 dB(A) (and 140 Pa) and 80 dB(A) (and 112 Pa), which determine when preventive measures are necessary to reduce the risks to workers. It is important to note that, when applying the exposure limit values, the determination of the worker’s effective exposure shall take account of the attenuation provided by the individual hearing protectors worn by the worker. The exposure action values shall not take account of the effect of any such protectors….

The directive also foresees detailed rules for the information and training of workers who are exposed to noise at work at or above the lower exposure action value.

Reinforced health surveillance is one of the main points of the directive: it confers, in particular, a right to the worker to have his/her hearing checked by a doctor or by another suitably qualified person under the responsibility of a doctor when the (132) Replacing Directive 86/188/EEC. 6.1. Noise in figures EUROPEAN AGENCY FOR SAFETY AND HEALTH AT WORK 99 upper exposure action values are exceeded. Preventive audiometric testing shall also be available for workers whose exposure exceeds the lower exposure action values, where the assessment and measurement of the noise exposure level indicate a risk to health.” (European Agency for Safety and Health at Work, Risk Observatory, Thematic Report 2, Noise in figures, Retrieved on October 25, 2018)

The new Noise Directive 2003/10/EC therefore reduces the exposure limit value from 90 dB(A), as set up in 1986 directive, to 87 dB(A), which represents clear progress.

Britain HSE allows users to calculate their daily doses of noise.

What are the Negative Effects of Noise?

Hearing loss can be categorized by which part of the auditory system is affected. There are 3 basic types of hearing loss: sensorineural, conductive and mixed

Sensorineural Hearing Loss – occurs when there is damage to the inner ear (cochlea) or hearing nerve in the brain.

Conductive Hearing Loss – occurs when sound is not conducted efficiently through the ear canal, eardrum or middle ear.

Mixed Hearing Loss – occurs when there is a combination of both sensorineural and conductive issues. In other words, both the middle ear and inner ear are affected.

Some causes of sensorineural hearing loss include:

- Aging – gradual age-related hearing loss is called presbycusis

- Excessive exposure to loud noise

- Viral or bacterial infections

- Certain Medications

- Meniere’s Disease

- Acoustic Neuroma a tumor which is located between the ear and the brain

- Hereditary factors

- Infection of the ear canal or middle ear

- Fluid in the middle ear

- Perforation or scarring of the eardrum

- Wax build-up

- Dislocation of the ossicles (three middle-ear bones)

- Foreign objects in the ear canal

- Otosclerosis

- Unusual growths, tumors

Excessive exposure to loud noise can be caused by a one-time or by repeated exposure to loud sounds or sound pressure over an extended period. Sound pressure is measured in decibels (dB). If a sound reaches 85 dB or stronger, it can cause permanent damage to your hearing. With extended exposure, noises that reach a decibel level of 85 can cause permanent damage to the hair cells in the inner ear, leading to hearing loss. Damage happens to the microscopic hair cells found inside the cochlea. These cells respond to mechanical sound vibrations by sending an electrical signal to the auditory nerve. The healthy human ear can hear frequencies ranging from 20Hz to 20,000 Hz. The high frequency area of the cochlea is often damaged by loud sound. Exposure to high levels of noise can lead to:

- Hearing loss;

- Tinnitus (ringing in the ear);

- Stress;

- Anxiety;

- High blood pressure;

- Gastrointestinal problems; and

- Chronic fatigue.

Worker’s Rights and Penalties

Workers have the right to:

- Working conditions that do not pose a risk of serious harm.

- Receive information and training (in a language and vocabulary the worker understands) about workplace hazards, methods to prevent them, and the OSHA standards that apply to their workplace.

- Review records of work-related injuries and illnesses.

- File a complaint asking OSHA to inspect their workplace if they believe there is a serious hazard or that their employer is not following OSHA’s rules. OSHA will keep all identities confidential.

- Exercise their rights under the law without retaliation, including reporting an injury or raising health and safety concerns with their employer or OSHA. If a worker has been retaliated against for using their rights, they must file a complaint with OSHA as soon as possible, but no later than 30 days.

For additional information, see OSHA’s Workers page.

What Happens If OSHA Standards Are Not Met?

American Penalties

“Last year, US business paid more than $1.5 million in penalties for not protecting workers from noise.”

“…an estimated 242 million is spent annual on worker’ compensation for hearing loss disability.” (www.osha.gov/SLTC/noisehearingconservation/, retrieved on October 18, 2018).

When health care facilities violate the regulations of the Occupational Safety and Health Act of 1970, the consequences the owners face can range from citations to jail time. Typically, the inspections are not planned. If a violation is found, the inspector will give the employer a deadline for fixing it and will issue a citation. OSHA schedules inspections based on several federal, regional, and local administrative priorities, but it also conducts inspections based on whistle-blower complaints and referrals.

If an OSHA violation is not corrected, OSHA will give a minimum fine of $5 000. OSHA can fine an employer up to $7,000 per day for not fixing a violation. The maximum fine for a repeated violation is $70,000. When a serious accident occurs, fines are certain or possible imprisonment.

Below are the penalty amounts adjusted for inflation as of Jan. 2, 2018. (OSHA Memo, 1/3/2018)

| Type of Violation | Penalty |

|---|---|

| Serious Other-Than-Serious Posting Requirements |

$12,934 per violation |

| Failure to Abate | $12,934 per day beyond the abatement date |

| Willful or Repeated | $129,336 per violation |

State Plan States

States that operate their own Occupational Safety and Health Plans are required to adopt maximum penalty levels that are at least as effective as Federal OSHA’s.

For More Assistance

OSHA offers a variety of options for employers looking for compliance assistance including on-site consultation, education programs for employers and workers. Yo su can contact their regional or area office nearest to you for additional information.

Canadian Penalties

“The legislation holds employers responsible to protect employee health and safety. Enforcement is carried out by inspectors from the government department responsible for health and safety in each jurisdiction. In some serious cases, charges may also be laid by police or crown attorneys under Section 217.1 of the Canada Criminal Code (also known as “Bill C-45”). This section imposes a legal duty on employers and those who direct work to take reasonable measures to protect employees and public safety. If this duty is “wantonly” or recklessly disregarded and bodily harm or death results, an organization or individual could be charged with criminal negligence.” (OH&S Legislation in Canada – Basic Responsibilities, retrieved on October 25, 2018)

European Penalties

Penalties can include the following:

- Fixed fines

- On-the-spot fines

- Remedial orders

- Probation for companies and directors

- “Might be used to underpin health and safety requirements – perhaps so-called ‘paperwork’ requirements: risk assessments, employee consultation arrangements, provisions for safety reps, compulsory insurance possibly, business registration, welfare provisions, and perhaps RIDDOR requirements.

- If used in conjunction with improvement notices, fixed penalties might have the effect of helping to change duty-holder behaviour – since, in the absence of a new approach, prosecution is rare in these areas.

- For use by enforcing authorities to relieve judicial system”

- Alternative penalties including:

“Penalties used instead of, or in conjunction with, criminal prosecution for breaches of health and safety law serious enough to warrant consideration of criminal prosecution, and which, in addition to a punitive and deterrent purpose, might also have a restorative or restitutive element. At present, such penalties are either not available within the health and safety system or are not used.

Such alternatives to prosecution would need:

-

- to fit the purpose of enforcement – that is, be effective in changing the behaviour of duty-holders and achieving improvements in health and safety outcomes, and

- to satisfy the principles underpinning the Health and Safety Commission’s (HSC)

Enforcement Policy: proportionality, targeting, consistency and transparency.”

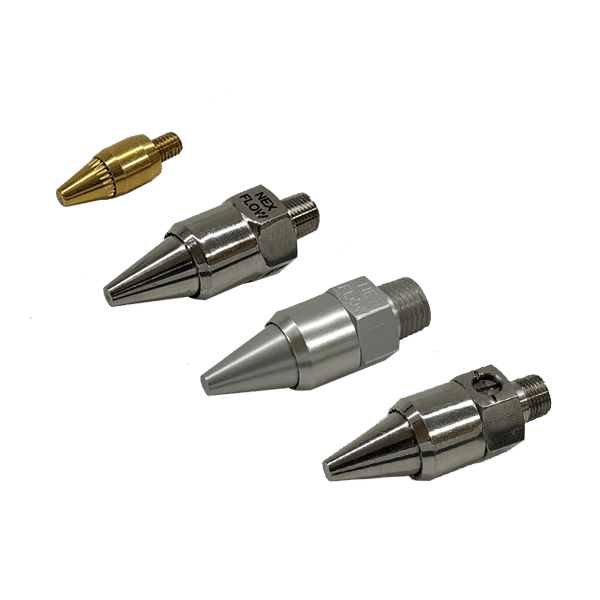

FEATURED PRODUCTS

Strategies for Lowering Noise Pollution

Here at Nex Flow, we take noise levels into consideration very seriously because we understand that reducing noise levels from very loud and damaging compressed air equipment is important. Compressed air technology is used for cooling or blow off applications. Properly engineered air nozzles and air amplifiers can reduce noise levels by 10 dBA and air knives can operate under 70 dBA for blow off applications.

Where compressed air is exhausted from exit ports, mufflers may be added to reduce noise levels. The mufflers that perform optimally are ones with a Coandă profile used to entrain surrounding air along with the compressed air released, which converts pressure to flow. The conversion accomplishes three things: noise levels fall dramatically, energy consumption is reduced, and a laminar flow is maintained at a greater distance than from an open pipe, tube or hole so the nozzle or other blow off device is effective at a much greater distance.

Sound level is proportional to the velocity of the compressed air flow exhausted by a factor to the power of 8. .

Sound Level ∞ Velocity 8

After mufflers are installed, the velocity can be reduced, which minimizes noise levels and also saves energy.

Conserve energy by turning off the compressed air tool when not in demand. This will also reduce noise in the workplace and save money.

Noise controls should reduce hazardous exposure to sound so that risk of hearing loss is eliminated or minimized. Not only will hearing loss be avoided, but communication between workers will improve. Air conditioning noise is unavoidable but investing in a new unit or noise absorbing equipment can reduce the noise output. Vortex Tube operated Cabinet Enclosure Coolers (Panel Coolers) operate under 80 dBA but have optional sound reducing packages to reduce noise levels to under 65 dBA. The noise measurement is typically taken about 3 feet from the source.

Modify, maintain, or replace aging equipment. Older air conditioners can collect dirt and other blocking materials over time. Best practices clean the air filters regularly. Internal parts, such as bearings of a fan motor, should be cleaned by a qualified technician. Fan motor bearings can also be adjusted to reduce noise. Vortex Tube operated Cabinet Enclosure Coolers (Panel Coolers) do not have these issues and offer advantages of near zero maintenance over traditional air conditioners for electrical and electronic cabinet enclosure cooling. They can be used in factory environments and only when compressed air is available for their operation. Other advantages they offer is no CFC’s or HCFC’s, keeping control panels at a slight positive pressure to keep out dirty environmental air, and no condensate. They maintain noise level consistently for years if the compressed air supplied is kept properly filtered.

Relocate noise-producing equipment (e.g., freezers, refrigerators, incubators and centrifuges) away from workers. Provide acoustic treatment for ceilings and walls. Controlling noise exposure through distance is often an effective, yet simple and inexpensive administrative control.

Note: Doubling the distance between the source of noise and the worker, the noise is decreased by 6 dBA.

Lower ceiling height to prevent sound from traveling and bouncing off surfaces, therefore amplifying noise.

Treat the noise source or the transmission path to reduce the noise level at the worker’s ear. Examples of inexpensive, effective engineering controls include:

- Use low-noise tools and machinery

- Maintain and lubricate machinery and equipment (e.g., oil bearings).

- Place a barrier between the noise source and employee (e.g., sound walls or curtains).

- Enclose or isolate the noise source.

- Operating noisy machines during shifts when fewer people are exposed.

- Limiting the amount of time, a person spends at a noise source.

- Providing quiet areas where workers can gain relief from hazardous noise sources (e.g., construct a soundproof room where workers’ hearing can recover – depending upon their individual noise level and duration of exposure, and time spent in the quiet area).

- Restricting worker presence to a suitable distance away from noisy equipment.

- Have workers use hearing protection devices such as earmuffs, plugs

Whenever worker noise exposure is equal to or greater than 85 dBA for an 8-hour exposure or in the construction industry when exposures exceed 90 dBA for an 8-hour exposure, the employer is responsible for implementing a hearing conservation program:

- Identify which employees are at risk from hazardous levels of noise.

- Informing workers at risk from hazardous levels of noise exposure of the results of their noise monitoring.

- Providing affected workers or their authorized representatives with an opportunity to observe any noise measurements conducted.

- Maintaining a worker audiometric testing program (hearing tests) which is a professional evaluation of the health effects of noise upon individual worker’s hearing.

- Implementing comprehensive hearing protection follow-up procedures for workers who show a loss of hearing (standard threshold shift) after completing baseline (first) and yearly audiometric testing.

- Proper selection of hearing protection based upon individual fit and manufacturer’s quality testing indicating the likely protection that they will provide to a properly trained wearer.

- Evaluate the hearing protectors’ attenuation and effectiveness for the specific workplace noise.

- Training and information that ensures the workers are aware of the hazard from excessive noise exposures and how to properly use the protective equipment that has been provided.

- Data management of and worker access to records regarding monitoring and noise sampling.

How does Nex Flow products reduce noise levels?

Compressed air exhaust air is a source of noise and why noise reducing products, such as air nozzles, air knives and air amplifiers are used in factories. To protect workers from excessive and damaging noise levels, the excess noise can be reduced up to 10 dBA.

The X-Stream® Sound Level Meter is used to measure and monitor the sound level in all types of industrial environments. The handheld accurate meter, which has data collection, is used to identify noise problem areas that may be intermittent. It is used for compressed air exhaust noise measurement and identifies where costly and inefficient blow off can be replaced by energy efficient Nex Flow®blow off products.

Nex Flow manufactures specialized compressed air solutions that are easy to install and reliable. All products offer noise reduction in factories to enhance the safety of your environments. Nex Flow manufacturers high quality, economical, specialized compressed air solutions for blow, off, cooling, drying, and moving with representatives worldwide. Choosing Nex Flow means that you obtain the best customized solution, including full technical support. Our customer technical support provides blowing angle and direction tips during installation. All compressed air products have a five-year warranty against manufacturer’s defects.