Pneumatics Articles Nex Flow

November 10, 2017

Some factors to consider in the use of compressed air blow off with static elimination is the strength of the charge on the part to be addressed, if you need air blow off and exposure time to the […]

November 8, 2017

This video outlines the conditions where vortex tube cooling units are best used for air conditioning electrical and electronic enclosures. Vortex tube-operated Cabinet Enclosure Coolers, or Panel Coolers utilize compressed air to operate, and that energy cost needs […]

November 5, 2017

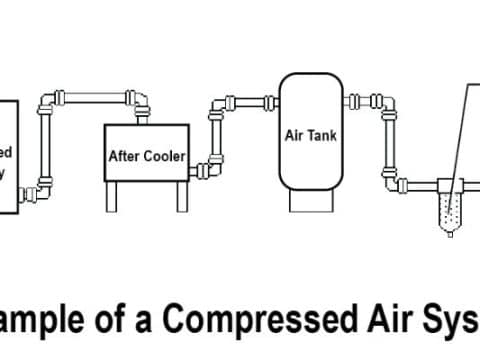

When compressed air is produced, it is first stored and then utilized from storage as it is needed. This has implications for actual energy use and cost. Storage in a compressed air system allows users to supplement energy […]

October 31, 2017

Things to be considered in the installation of a Panel Cooler, a vortex tube operated air conditioner for electrical and electronic enclosures. If you have any questions on the use of compressed air for cooling, blow off, cleaning, […]

October 27, 2017

Some months ago I posted the above pic with a short comment but with little explanation of how it worked so I will explain it more now. Extruded profiles come in many shapes and configurations but the Ring […]

October 23, 2017

Packaging of goods has gone beyond simple containers, bottles and cans such as the one depicted in the picture above. This particular packaging of pet food needs to be dried after washing. With limited space and a concern […]

October 19, 2017

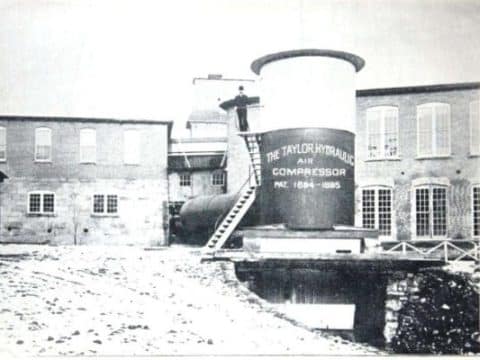

THE HYDRAULIC COMPRESSOR History In doing some research on developments in compressed air technology I came across a fascinating bit of Canadian history at: http://www.coppercountryexplorer.com/2011/07/the-taylor-compressor/ Imagined and built by Canadian Charles Taylor, this amazing compressor supplied all the […]

October 13, 2017

Formal compressed air system audits are costly and can be quite involved,. Experts are available to do this with expensive equipment in very large factory operations. But what about smaller facility where the cost and time is hard […]

October 10, 2017

An efficient application for compressed air operated venturi’s like Nex Flow’s Ring Vac units ( see www.nexflow.com) is hopper loading. Whether it’s loading resin for a plastic molding process, or a hopper of bottle caps for a bottling […]

October 5, 2017

In any good compressed air system there is a receiver which stores compressed air. One of the advantages of compressed air is that it is an “on demand” source of energy. When it is not needed, it can […]

October 2, 2017

A 100 cfm compressor with a refrigeration drier, operating for 4000 hours in a temperate climate, can produce about 2200 USgal of liquid condensate in a year! Failure to remove this moisture can result in condensation in the […]

September 28, 2017

WHEN USING COMPRESSED AIR While it is known that compressed air is costly to use, there are still things that happen on the shop floor that creates a great deal of waste. The key to maximum efficiency in […]

September 19, 2017

Compressed air noise can be responsible for up to 1/3rd of the noise in a factory operation. So controlling noise from compressed air is important. This can be achieved with the following three steps: 1. Use control devices […]

September 17, 2017

High velocity compressed air blow-offs are especially useful if parts don’t need to be “super dry” (as completely free of water) or if there is a requirement to remove “excess” water or other liquid from a part prior […]

September 11, 2017

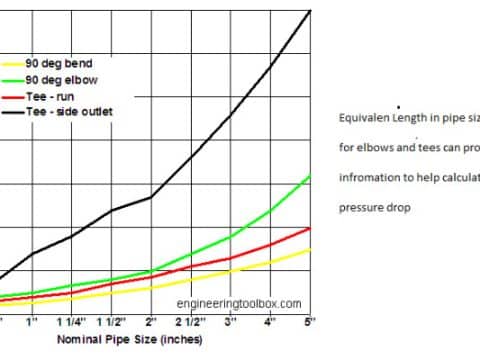

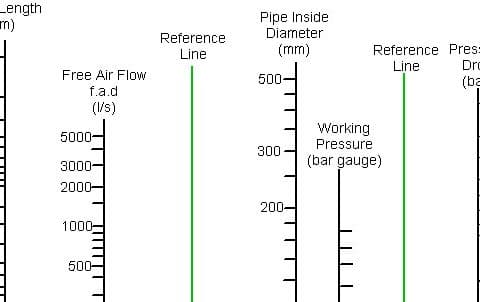

Compressed is a friendly and reliable energy source used for many applications but sometimes not enough thought is given to the “pressure drop” when using the air. Pressure drop is the loss of pressure due to energy loss […]

September 8, 2017

Lottery Ticket Quality Control with an Air Knife Unusual applications for compressed air are always fun. One such unusual application was at a facility printing lottery tickets. Printing lottery tickets is much like printing money as they need […]

September 5, 2017

Compressed Air Operated Air jets Compressed Air Operated Air Jets are ideal for applications such as part ejection and can provide advantages over air nozzles in some applications. Video url : https://youtu.be/TQmdj_J-w4s

September 4, 2017

In steel sheet production or other metal sheet production, which is better to use for blow-off? – a series of many small compressed air operated flat jet nozzles or, one or more long compressed air operated air knives? In […]

September 2, 2017

Compressed Air Flow Amplifiers and Back Pressure Issues. Compressed air flow amplifiers (also called air movers) operate using something called the Coanda effect to convert pressure to flow with minimal energy loss. The result is high flow and less […]

August 30, 2017

This article is borrowed from a blog by the Marshall Institute at www.marshallinstitute.com Teaching the Millenials a sound reliability strategy early in their career (the Matures, Baby Boomers and Gen Xers too) can be the critical component of a strong manufacturing strategy. […]

August 23, 2017

Compressed Air Operated Air Knives come in two styles and can both save energy and reduce noise levels as well as improve factory safety in both blow off and Compressed Air Cooling applications.

August 20, 2017

A happy person is a productive person but working in an environment where you sweat all day is not fun. Even in the winter time in cold countries it can be very hot and uncomfortable working in factories such […]

August 16, 2017

Cameras are used extensively in production for monitoring to insure quality and are often exposed to hot and harsh environments and may require additional cooling. The most common way to cool an industrial camera in very hot environments is to enclose it in a […]

August 13, 2017

The point of use filter is a major center which maintenance is important in a compressed air line. An area of major importance is point of use filtration in compressed air lines. This simply means that a filter (should be) […]

August 10, 2017

Using a vortex tube video covering the industrial environment use. This video illustrates some of the things to keep in mind when using vortex tubes in industrial applications. Video url : https://youtu.be/3OIjke1lcwo Welcome to EZ Engineering! Today, […]

August 7, 2017

Point of Use Filtration in Compressed Air Compressed Air technology for blow off an cooling involves the use of air flow amplifying products in the form of air nozzles, air movers and air knives used in blow off, […]

August 4, 2017

August 1, 2017

Easy Engineering Easy Engineering is a continuation of a series of educational videos to explain special compressed air-operated items for blow-off and cooling, moving on to what they are made of, how they work, and how to use […]

July 28, 2017

A vortex tube is an interesting device that takes compressed air and divides it into a hot and cold stream. Various theories try to explain why it works but there is no definitive answer. Their primary uses are […]

July 25, 2017

Easy Engineering is the first in a series of educational videos to explain special compressed air operated items for blow off, cooling and moving on what they are made of, how they work and how to use. OTHER […]

July 21, 2017

USING A RELIABLE VORTEX AIR CONDITIONER AS A BACKUP UNIT A vortex air conditioner like a Nex Flow Panel Cooler is probably the most reliable type of system you can use in air conditioning control panels as it […]

July 17, 2017

In choosing a company to deal with, you should look at the values that drive them. Company values are the guiding principles and fundamental beliefs that help us function together as a team and work toward a common […]

July 14, 2017

Filters are an important component in any compressed air system. Clean, dry, and even oil free compressed air and gas is a basic need for many industries. In some applications even a drop of unwanted oil or dirt […]

July 12, 2017

IMPORTANT GUIDELINES IN USING COMPRESSED AIR 1. Hoses and lines should be rated to meet the maximum operating pressure of the equipment – avoid using weak plastic tubing in open factory environment as they can split and cause […]

July 9, 2017

Anodizing is an environmentally safe electrochemical process that converts the aluminum metal surface into a porous aluminum oxide, ultimately creating an end product whose finish is more durable and weather-resistant. Aluminum anodizing enhances the characteristics of aluminum in […]

July 5, 2017

Imagine a factory environment – maybe a fertilizer plant or a chemical production facility with electrical and electronic cabinets that need to be kept clean. Not only does the maintenance cost of maintaining the air conditioning systems become […]

July 3, 2017

One of our customers made a very nice setup to dry extruded pipe using Ring Blade Air Wipes manufactured by Nex Flow Air Products Corp. Very easy to switch out one Air Wipe diameter with another size, as […]

July 2, 2017

Variable Frequency Drives describe equipment used to control the speed of machinery. Many industrial processes such as assembly lines must operate at different speeds for different products. Where process conditions demand adjustment of flow from a pump or […]

June 29, 2017

In some industrial casting and forging situations the items made need to be cooled quickly for handling purposes or for an on-going process such as marking or assembly, otherwise the processes cannot be completed properly or handling would […]

June 25, 2017

Late October, 2016 there was a landmark agreement among 170 countries to set firm dates for the curbing the use of HCFC’s in air conditioning systems with penalties for non-compliance. Developed countries must reduce their use of HFCs […]

June 21, 2017

How to have Control Panel Air Conditioning meet the requirements of the Kigali Agreement On Oct 15, 2016 countries around the world signed on to the Kigali Agreement, an amendment to the Montreal Protocol, which hopes to reduce […]

June 17, 2017

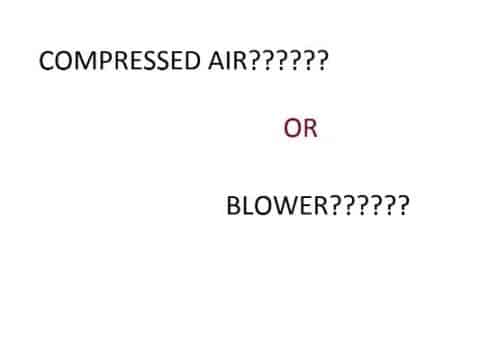

Compressed air is viewed as a costly method for blow off and cooling applications and some look to electric motor driven blowers as a replacement. This is a reasonable with a focus for energy saving being a major […]

June 14, 2017

In cleaning statically charged products there are claims by some companies that static can be removed as far as 20 feet away. What they do NOT say is how fast. This can lead to disastrous applications in manufacturing […]

June 8, 2017

Both low pressure blowers and high pressure compressed air is used for blow-off and cooling applications. Much has been made of the higher energy cost in using compressed air over the last 15 to 20 years which all […]

June 5, 2017

Several companies manufacturer vortex tube operated air conditioners primarily for electrical and electronic enclosures. Some promote them as the solution to all applications when in fact that is not the case. There are many types of devices on […]

June 1, 2017

With the advent of new technologies, manufacturing will be transitioning in ways that not even science fiction could foresee. Some trends to note… 1. New techniques such as 3D printing will eliminate the need for many products now […]

May 30, 2017

Why Vortex Tube Panel Coolers are getting used more for Cooling Electrical Panels Vortex tubes create freezing air from compressed air and are used as air conditioners for cooing control panels – even cameras in hot environments. Main […]

May 27, 2017

Of the roughly 40 million Americans suffering from hearing loss, 10 million can be attributed to noise-induced hearing loss. With extended exposure, decibel levels of 85 or more can lead to hearing loss. Exposure to impulse or continuous […]

May 20, 2017

When a compressed air flow amplifier gets dirty, there is no need to remove the units from the line. Nex Flow compressed air-operated Air Amplifiers are annular flow amplifiers often called “air movers.” They utilize the Coanda effect […]

May 16, 2017

Recognizing the effect of pressure drop in your compressed air system is essential to ensure your equipment is working optimally. Except for possibly compressed air leaks, the greatest waste of using compressed air is not addressing unnecessary pressure […]