LOUDER DOES NOT MEAN MORE POWER

Have you ever heard someone said something along the lines of “well that’s definitely a powerful machine – just listen to how loud it is”. While this may be true some of the time it is not always the case. When working with compressed air, having a well-designed machines and accessory that is equally powerful at a much lower noise level is always a plus. Here are some things to consider about noise.

Loud Noise Means Less Efficiency

Have you ever tried to concentrate with loud noise? It is much more difficult to think clearly with loud noise. But it’s not just personal efficiency that can be negatively affected, the efficiency of the device making the noise can also be jeopardized. For instance, the noise involved with compressed air blow-off can mean a leakage or an inefficient design. It is still prevalent to use open tubes and jets and drilled pipe for blowing compressed air in production applications to clean, cool and move products. However, the exhaust noise using these methods can exceed 90 dBA depending on the pressure used and the bulk of the noise generated by this method of blowing with compressed air is from the energy lost as it exits the tube or pipe. In other words, the energy is loss as noise and pressure drop because the flow and force from dilled pipes and open tubes are mostly turbulent.

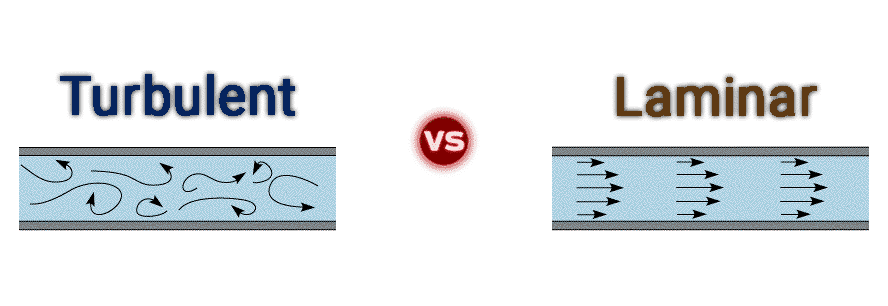

Turbulent Flow can be characterized as having tiny whirlpool regions and it also increases the amount of air resistance which is useful for accelerating heat conduction and thermal mixing. However, it is not useful for blowing applications. Turbulent flow will produce a great deal more noise. For blowing with compressed air, whether for cooling or cleaning or drying, laminar air flow is preferred.

Laminar Flow is when the flow of a fluid (in this case, air) follows a smooth path, or paths which never interfere with one another. One result of laminar flow is that the velocity of the fluid is constant at any point in the fluid movement path.

Just how much can noise be reduced and how much energy saved using blow off products that produce a laminar flow? The answer is – quite dramatic. A laminar flow nozzle can reduce noise levels as much as 10 dBA and reduce energy consumption by 30% – 40%. Likewise, laminar flow air knives which is basically long, flat nozzles are used to replace drilled pipe for higher efficiency. Some designs are extremely quiet and can reduce exhaust air noise to as low as 69 dBA.

High Noise Level is a Hazard

Of the roughly 40 million Americans suffering from hearing loss, 10 million can be attributed to noise-induced hearing loss (NIHL). NIHL can be caused by a one-time exposure to loud sound as well as by repeated exposure to sounds at various loudness levels over an extended period of time.

Sound pressure is measured in decibels (dB). The average person can hear sounds down to about 0 dB, the level of rustling leaves. A handful of people with very good hearing can hear sounds down to -15 dB. On the other end of the gauge, a sound that reaches 85 dB or stronger can cause permanent damage to your hearing even if exposed for a very short time. The timespan you listen to a sound affects how much damage it can cause. The quieter the sound, the longer you can listen to it safely. A very quiet sound will not cause damage even if you listen to it for a very long time. However, a sound that reaches 85 dB can cause enough damage to induce permanent hearing loss. Here are some common sounds.

- A typical conversation occurs at 60 dB – not enough to cause damage.

- A bulldozer that is only idling (not actively bulldozing) is loud enough at 85 dB – after only 8 hours it can cause permanent ear damage.

- When listening to music – a stock earphones at maximum volume can generate sounds reaching a level of over 100 dBA. Loud enough to begin causing permanent damage after just 15 minutes a day!

- A clap of thunder from a nearby storm (120 dB) or a gunshot (140-190 dB, depending on weapon), can both cause immediate damage.

It is estimated that as many as 30 million Americans are exposed to potentially harmful sounds at work. Even outside of work, many people participate in recreational activities that exposes them to harmful noise (i.e. musical concerts, use of power tools, etc.).

Designing the Future of Air Blow Off Technology

Nex Flow® Air Products Corp. continually perform and fund research to constantly improve the efficiency and safety of compressed air accessories. With this approach, we are able to offer noise reduction for compressed air technologies that are equally or more efficient than competitive units.

Air Nozzles

Our Air Nozzles are engineered to reduce noise by 10 dBA over open pipe, tube or jets and maximize laminar flow to increase force/compressed air consumed.

One of the oldest styles of air saving, noise reducing air nozzles are of a cone shaped design. But if you put every single design next to one another both energy saving and noise reduction will vary greatly because many times the aerodynamic design is neglected. Having the nozzle outside appearance as a cone shape in not enough. There are many other (proprietary) factors to consider to truly minimize turbulence and maximize laminar flow. The cone shaped designs are still the optimum style to use for maximizing total volume of flow produced per quantity of compressed air consumed and is especially ideal for cooling applications. Where cost is a factor, this model is ideal.

The Air Mag is another one of our engineered nozzle with patented design. The bullet shaped design trumps the cone shaped design for producing the highest force/quantity of compressed air consumed. The patented design allows the Air Mag to provide the furthest distance for laminar flow compared to competitive units. Other bullet shaped nozzles need to be close to the target as turbulent flow begins to occur after only a short distance from the nozzle. Our unique design helps significantly extend the range of the laminar flow. Due to increased complexity and manufacturing processes, they are more costly than the cone shaped designs. However, they are the best option for when force produced is an important factor.

Air Knives

When replacing drilled pipe with holes, the Nex Flow Silent X-stream Air Blade air knife lives up to its name. At 80 PSIG the unit is runs on just 69 dBA exhaust noise and uses the same air consumption as if running competitive units at 60PSIG. Extremely popular as they often replace competitive units in the field because of the design and quality of manufacture.

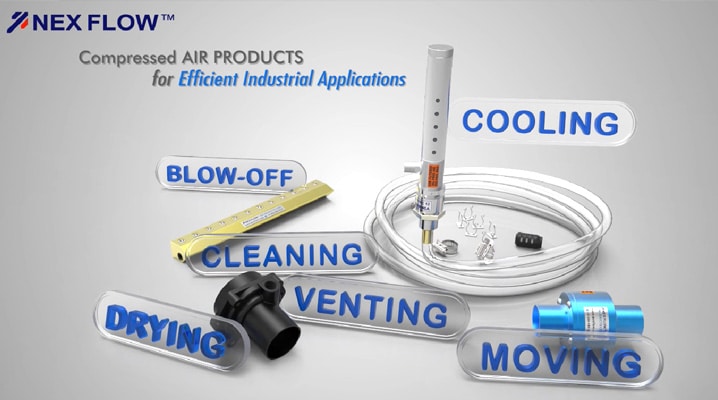

Other blow off products we offer include air flow amplifiers, air jets, and many more. Our accessories are used not only for blow off and cooling applications but can also be used for conveying, cleaning and to control static electricity.

The next time you hear a loud sound when using compressed air anywhere in the production line, don’t forget to check and see what is making that noise. Loud noise is a health hazard and is often wasted energy. So, if the source of the noise is coming from an open tube, open pipe or a drilled pipe of any sort, chances are, you can reduce this noise very quickly and even reduce energy and get better performance by using low cost products from Nex Flow®.