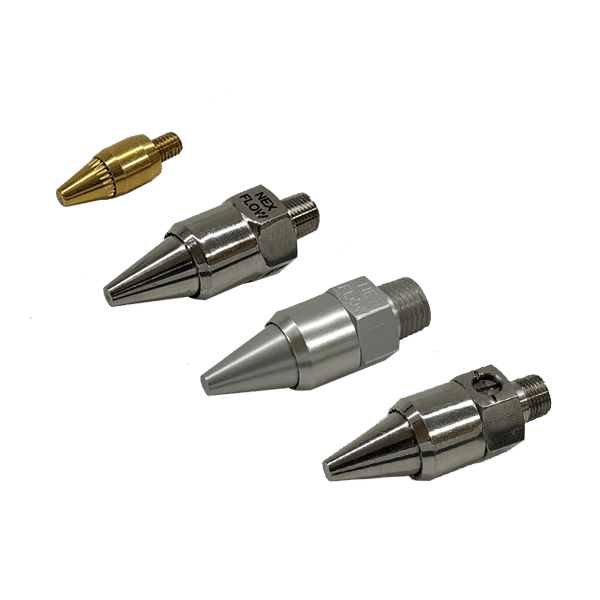

It is popular now to use the term “engineered” air nozzle for compressed air nozzles used for blow-off applications. But what is an engineered nozzle? The original close air-operated engineered nozzle is a cone shape that draws in surrounding air utilizing the “Coanda” effect and converts pressure to flow by removing atmospheric air and the nozzle’s compressed air. Copies and different physical sizes abound in the marketplace, but are they really engineered? The size, the angle of the hole, and even how the air flows inside and out of the air nozzle are essential. It can be easily proven by taking two similarly looking cone-shaped nozzles from different manufacturers and testing them side by side. Even if they look similar on the outside, they may perform dramatically differently, perhaps being louder (or quieter) and the other more (or less) powerful. A truly engineered version will consider inside and outside flow characteristics. But these cone-shaped designs generally provide the most “flow” amplification.

For most applications, however, force is more important, so a high ratio of force/air consumption (CFM) is essential. The “bullet” shaped finned nozzles with holes in between the fins seem to provide this optimum force/cfm better than the cone-shaped versions. The bullet shape still entertains the Coanda effect to accelerate outside air to produce more flow. As with the older designs, the number of holes, their size, overall shape, and fin design are essential but also the way the air flows on the inside. Copies of these bullet-shaped nozzles have also appeared but rarely perform even close to the original designs because they are poorly copied and not engineered. As with the cone-shaped styles, this can be quickly confirmed by taking two similar-looking nozzles from two manufacturers and comparing the force each produces at the same line pressure. The copy rarely does as well.

What Is An Engineered Air Nozzle Really!!

A few years back, so-called Laval effect nozzles, which have the compressed air exiting the nozzle using an hourglass-shaped exit to accelerate the exiting compressed air, appeared on the market. However, it is questionable whether they are any more practical for a higher force/cfm ratio than nozzles using the Coanda effect, incredibly if not close to the target of the blow-off. Noise is another factor with this style of the nozzle.

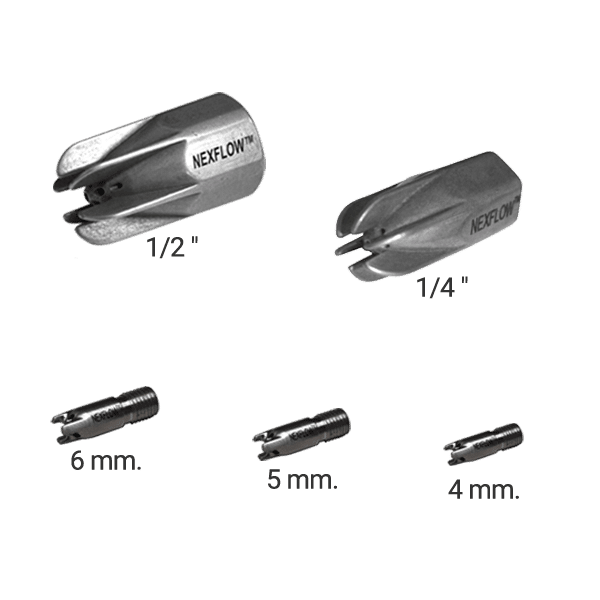

A bullet-shaped nozzle developed by Nex Flow Air Mag nozzle series is patent pending where the air exit nozzles are oriented in such a way as to increase the force/cfm over the best competitive nozzle found by about 10% and make it more effective at a greater distance. This is truly an engineered nozzle, and all factors, both inside and out, are considered. At the time of this writing, the available Nex Flow Air Mag sizes are 1/4″, 1/2″ but 4, 5, and 6 mm small nozzles are pending. A 1/8″ adaptor for the 6 mm nozzles will also be available.

So when looking at engineered nozzles, carefully research the actual force/CFM, at what distance and line pressure the specifications are taken, and the distance of their effectiveness to make sure it is genuinely engineered and will be suitable for your application. Stay with brand names like Nex Flow to assure quality and be wary of copies.

Nex Flow Air Products Corp. manufactures compressed air technology for blow-off, drying, cleaning, cooling, and moving and constantly strives to improve its products” performance and quality.