Nex Flow offers compressed air consultation on the use of compressed air “after” the air compressor room to optimize the use of “what you have” so as to minimize waste and cost while getting the most use out of the compressed air you can supply. It is important to note that with compressed air, even a small change can affect other parts of your factory system. We can advise where and how to adjust where necessary. We do this by telephone consultation to keep your costs low and to provide a suggested solution that you can immediately implement.

We do NOT do audits and compressor room analysis. For that there are many auditors that can go on site and provide you with detailed reports and they can also do on site evaluations in great detail which may be beneficial to your company. Our place is to solve immediate problems and assist in any planned changes related to compressed air.

Compressed Air Consultation

Examples of assistance:

A company had severe water content problems in its compressed airlines. The company had several air compressors and each compressor or bank of compressors had an air receiver with an automatic drain that was working properly. In addition, they had a working aftercooler in the system, and even a refrigeration air dryer to address moisture content in the compressed air lines. Basically – they did everything right! But… they still had moisture at most point of use areas. In consultation and with their subsequent follow up of items they were asked to check, we were able to identify the probable causes of the problem. These probable causes were also not very easy to address either due to time or cost or both. However, we were able to recommend a cost-effective solution to eliminate the problem with minimal interruption of production.

Another company had several areas of air pressure below what is necessary to operate their equipment and even for several blow-off applications. Initially, they simply boosted the compressor supply pressure to attempt to overcome this lack of adequate pressure. It worked for some period of time but then the problem returned. After the consultation, the company was directed to check certain aspects of their system which identified the main culprit to be leaks in certain areas of their system. Increasing the main pressure only resulted in making the leaks worse over time. In addition, continual expansion of the plant over the years had some piping out of balance. Once these leaks were corrected, and additional piping installed to compensate for unbalanced airflow (and therefore greater pressure loss) the air pressure at the compressor end was reduced and equipment operated normally and will less energy loss.

A firm required advice on the filtration required for their process. Filtration requirements vary with the industry and with the application within an industry and direction was provided to obtain the information required for their application. Sometimes it’s just a matter of simple direction to find the information needed saving a great deal of research time for the customer.

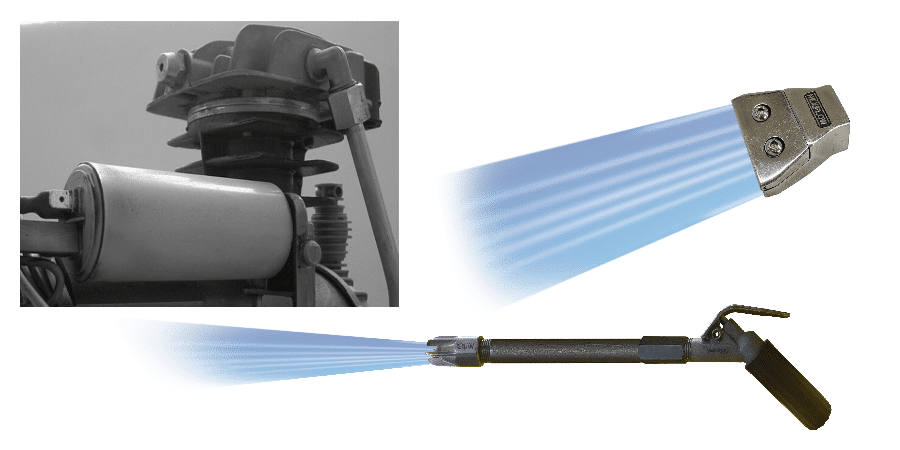

One of the most misunderstood and energy-consuming areas is the use of compressed air for blow off – whether it’s for cleaning, drying or part ejection. It is energy intensive (70% of compressed air is used for blow off applications), loud due to heavy exhaust and impact noise, and can be highly sensitive to back pressure, dirt and particulate and moisture. To add to the confusion there is a plethora of air nozzles, and all kinds of compressed air blow off products on the market, sometimes with dubious performance claims. With on line consultation we provide the guidelines during the conversation to address the particular application in deciding whether you need compressed air, and if so, which blow off product is most applicable and how to decide on the optimum product. For example, there is one customer who uses a tremendous amount of compressed air for blow off applications but the system and environment are such that blowers are out of the question, but so are air amplifying nozzles due to the environment surrounding the compressed air exhaust. So other suggestions are necessary for energy and noise reduction.

Another misunderstood and often misrepresented is the use of compressed air with static elimination for static removal at a distance and also for cleaning. One still sees ridiculous advertisements claiming to remove static charge at 20 feet away with the implication that it is instantaneous. It is not! There was a customer that was using air knives with static elimination bars (ionizing bars) in a rather high speed application mounted about 8 inches from the target. It failed to remove static charge. There was a second customer with the same problem; a static charge that was attempted to be removed using air knives with a static bar. In both cases the static bar could not be placed close. The solution was actually just a much stronger static bar. In fact, the air knife was not even necessary. We have the experience to recommend the correct static removal system and whether or not a blow off is required. There have been great advances in static control with very strong static elimination systems to address high speeds and high static charges. Compressed air is necessary usually and primarily to clean and remove particulate from statically charged surfaces once the static charge is removed. The air does carry the “ions” from a static eliminator further but as it does so, the ions begin to dilute. They do remove static charge at a distance but, the time to remove also increases. A static eliminator will remove a static charge even at a large distance “given time” but never instantaneous.

Spot cooling utilizing vortex tube technology is another area that is not well understood. There is both old and new technology available in vortex tubes to address spot cooling applications, each with its range of applications. For example, a customer wanted to cool a large area with vortex tubes but was directed to using air amplifiers instead as the energy cost and area limitation of vortex tubes in open space is limited. On the other hand, new vortex tube technology has been applied to a cool an enclosure in a very hot environment that traditional vortex tubes cannot accomplish effectively. Vortex tube technology, while utilizing compressed air is still a viable solution for many spot cooling and enclosure cooling applications due to the compact nature of the product and specific advantages they offer, in particular when applied in difficult, hot and dirty environments and where flexibility is important and where space may be a premium. There are many factors that affect the performance of a vortex tube or vortex tube operated product such as tool coolers and panel coolers and it is important to understand them for optimum and efficient performance. One important consideration for the use of this technology in electrical and electronic enclosure cooling is the importance of proper electrical approvals for the local market such as Underwriters Laboratory or equivalent to assure the enclosure is not at risk for damage during cleaning and the materials of construction will withstand the environments in which they will be used. If there is no approval, their use should be suspect.

Conveying of materials with the use of compressed air is advantageous in many applications, especially if intermittent. For example, venturi style units used to load plastic pellets into hoppers are popular as they are instant on and off, lightweight, compact, and easy to use. However there are many other applications where such systems can replace electric operated vacuum pumps. For example, there is a customer who had researched the replacement of vacuum pumps used to exhaust gas from a system which we cannot mention here as it is proprietary. The air operated conveyors were made of PTFE due to the nature and temperature of the gases involved and provided a much more cost effective, and virtually zero maintenance method of exhausting this gas. Both Coanda operated air amplifiers and venture style units may be used for gaseous conveying and certain factors determine which is most effective and appropriate. Of course, conveying of materials is the most common application and optimized performance depends of several factors. Whether or not a compressed air operated system or an alternative is appropriate can be determined thru online consultation.

As the examples indicate, we are available to consult on questions you may have to address immediate problems you may have regarding your compressed air system outside of the air compressor room and to offer a solution, as well as to offer guidance in any planned application you may have for compressed air so that the optimum product range is chosen.