What causes static charges and why control it?

Active vs. Passive Static Eliminator

Plastics, glass and other insulating materials generate a static charge when rubbed, cut, and stretched. Hot or warm plastics will generate a static charge as they cool. In many production processes this can cause any of the following problems:

- Static charge will attract dirt particles. If the part needs to stay clean for further processing such as painting, coating or even just packaging, these particulates can be a major issue.

- As the product moves along the manufacturing process, materials such as film may bend or warp due to static and cause jamming of machinery, and hence downtime.

- If the static charge is high enough, it can cause sparks and discomfort or even harm to personnel working with the material that is statically charged.

For these reasons, static charge needs to be eliminated or at least reduced and controlled. So how does the static charge get generated in the first place? Static electricity is the result of an imbalance between negative and positive charges in an object. These charges can build up on the surface of an object until they find a way to be released or discharged.

The rubbing of certain materials against one another can transfer negative charges, or electrons. For example, if you rub your shoe on the carpet, your body collects extra electrons. The electrons cling to your body until they can be released. As you reach and touch your pet (which is being really mean!) or perhaps a door knob, you get a shock. This same process occurs in a production line.

There are two ways to address a static charge. One is with a passive static eliminator and the other is with an active static eliminator.

Passive Static Eliminator

Some Passive static eliminator examples include: Copper Tinsel, Nylon Brushes, Sharp Edged Metal Strips, Antistatic Flexible Rope and Anti-Static Spray. These passive devices usually only reduce the charge with the exception of antistatic spray. In some situations – a reduction in the static charge may be adequate, however there are limitation with these passive devices. For rope and tinsel, it can potentially be dangerous when they break off and also has the potential to fall onto the material being processed. Antistatic spray may not be used if the statically charged part cannot tolerate a liquid for any reason. Brushes are limited to slow moving and lower static charges – most commonly used with printers, fax machines, and elsewhere where static only needs to be reduced to avoid sticking of the sheets.

Using passive static control may help in preventing some machine jamming and address employee discomfort but because it does not eliminate static completely (except for antistatic spray) it will usually not be enough to address dirt problems caused by static. Sprays have the disadvantage of being an endless consumable and an on-going cost that can add up over time. If the charge is very high, a passive device may knock the charge down to an extent but still leave a very high static charge that needs to be further addressed. This is when active static elimination is needed.

Active Static Eliminator

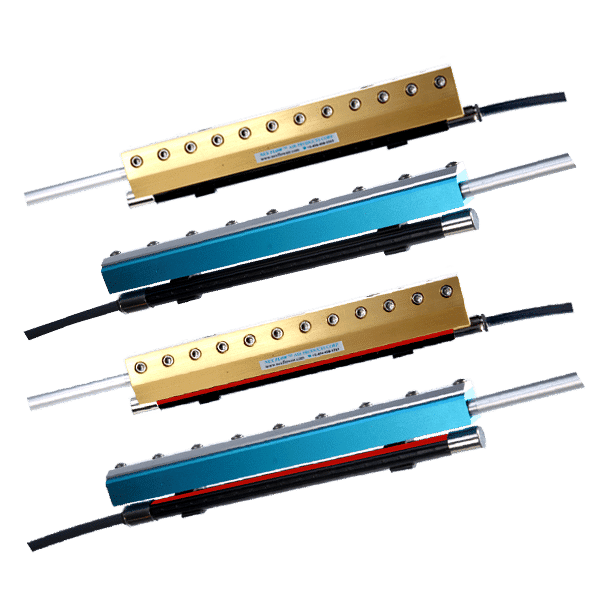

Active static eliminators (static bars or ionizing bars) are electrically operated and can be either AC or DC systems. DC systems are designed to work farther away from the target but are usually more costly than AC systems. On the other hand, AC systems normally work close to the statically charged product to remove the static charges. That being said – a more powerful AC system such as the High Voltage VS bar offered by Nex Flow is available which works at a further distance depending on the speed of the target. Active systems essentially ionize the oxygen molecules of the surrounding air which get attracted to the charged surface, thereby neutralizing the charge that the air “sees” (come in contact with).

Active systems work by generating alternatively a negative and then a positive charged ion. Whatever the charge on the surface is, the oppositely charged ion will remove it. Active systems can remove almost, if not all the static charge from the surface of a statically charged part. There needs to be an adequate number of ions for the level of charge needed to be addressed as well as some dwell time over the charged area. The faster the target moves the less dwell time is available for the static eliminating ion to remove the static charges. So for fast moving materials, you need a more powerful static bar – either high powered AC system or a powerful DC bar. Keep in mind that the distance from the target also matters. The further the bar is positioned, the longer it takes for the ions produced to arrive at the target and as they travel some will recombine. The result is less concentrated eliminating ions reaching the target surface.

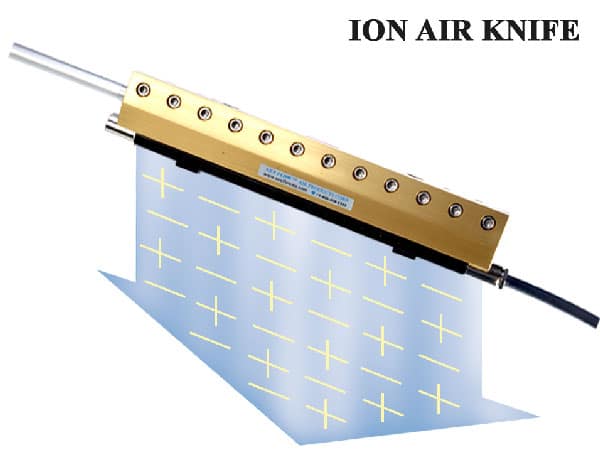

Combining an Air Knife to a Static Bar

One way to help make a static bar work further away is to push the ions with either low pressure compressed air or with blower air. There is a myth perpetrated by some companies that make air knives, claiming that you can remove static charge at a ridiculously large distance just by adding a compressed air operated air knife. This is not entirely accurate. It is true that compressed air operated air knife, being laminar will push the ions and have much less of a recombination of ions than pushing these ions with a turbulent flow, but some recombination will still occur. So the further away the static eliminator bar is placed from a statically charged target, more dwell time will be needed to remove the static charge.

The only way to address a very high static charge or a fast moving target at a great distance from the target is with a stronger static bar that produces more ions – not by just using a compressed air operated air knife. History has proven this. If a static bar works at a moderate distance to the statically charged surface, it will probably still work if the static bar is combined with an air knife, on a moderately charged surface and at moderate speed. But to truly eliminate static charge farther away or at high speed, you actually need a stronger AC bar or a DC bar, with or without an air knife.

The real purpose of an air knife, whether blower operated or compressed air operated is to clean the parts. Dirt particles that stick due to static charge cannot be blown off easily because they get attracted back to the surface, even if loosened by a blast of air. By combining a compressed air knife with a static bar (ion air knife), the ions that get pushed by the laminar air flow eliminate the static charge allowing the static particles to be easily removed. Once the static charge is gone, it takes very little energy to remove the particles, so the air pressure can be as low as 2 – 3 PSIG in many cases. Blowers combined with static bars also work but because of the nature of the air flow with blowers, they need stronger or double static bars to do the same job and should have a high mass flow. In many instances, if the air flow is intermittently used, the energy cost of a compressed air knife static systems to blower air knife static systems are about the same. The advantage of a compressed air versions is that it is much quieter, simpler, compact, and is less costly to install and maintain. Nex Flow offers compressed air operated air knife systems with standard as well as with extra powerful static bars.

Combining an Air Amplifier to a Static Bar

Another version combining compressed air with static control is using an annular compressed air amplifier with a point ionizer (spot ionizer). This produces a laminar cone of ionized compressed air to blow onto the charged surface. Some applications include neutralizing the inside of blow molded or injection molded containers to loosen and remove plastic pieces and strings inside due to cutting processes. Another application is to blow off plastic strings and pieces after a molding process form the mold itself. Again, all these particles stick due to static charge. Our Ion Blaster Beam is a point ionizer attached to a compressed air amplifier via a plastic attachment. The attachment should be plastic to avoid the grounding effect of metal that would reduce the effectiveness of the ions generated. This is one of the reason why our Ion Blaster Beam works up to 30% faster than competitive units of similar design but with metal attachment.

Manual Static Elimination

For manual static elimination, an anti-static air gun is best and for the same reason stated above. Dirt particles are not easily removed if they stick to the surface due to static. Only by removing the static charge can a surface be cleaned. As with air knives and with the annular amplifiers combined with a static eliminator, once the air from an anti-static air gun neutralizes the charge on the part, particles can be blown off with minimal pressure and minimal compressed air consumption.

In summary

There are passive and active static control systems. Active static control is the only means to eliminate static charge completely and not adversely affect the end product. If the static elimination system is far from the statically charged target, or if the target is fast moving, or has a very high static charge, you need to use a more powerful static eliminator or increase dwell time.

The main application for using compressed air knives and amplifiers with static eliminators is more so for cleaning the charged surface and less so for pushing the static eliminating ions. That said, compressed air knives and amplifiers with static eliminators can be used at very low pressures and, especially when used with on-off control the energy cost is comparable to using blower systems. The advantage is that compressed air operated static eliminators are low cost, compact, quiet, simple and easy to use with minimal maintenance.

For manual cleaning operations an anti-static air gun is ideal and can save a great deal of energy because you can clean with less pressure than using the air gun solely.