Product Overview

Stainless Steel Standard Air Blade Air Knife

The Standard Stainless Steel Air Knife from Nex Flow® is easy to install and maintain. It can reduce both compressed air consumption and noise levels. used to blow off liquid or debris from products as they travel on conveyors.

Built and designed for significantly longer life in difficult environments than many competing products. Flexible mounting options and easy to fit in small spaces. Energy reduction in compressed air use up to 90% and noise reductions of 10 dbA. Maintenance free with output easily controlled, safe to use.

Stainless Steel Standard Air Blade Air Knife produces a “laminar” flow of air using the Coanda effect. This draws a large volume of air from the surrounding area along with the small amount of compressed air from the Air-Blade. It also produces an output flow up to 30 times.

Features / Advantages

- Quiet – 72 dBA for most applications

- Uniform airflow across entire length

- Minimal Air Consumption

- Variable force and flow

- No moving parts – maintenance free

- Easy mounting

- Compact, rugged, easy to install

- Stainless steel screws in all models

- 30:1 air amplification

- Anodized Aluminum to protect the surface of aluminum versions

- Stainless Steel shim

- 303/304 stainless steel for high temperature and corrosive environments

- Surface entraining the air can be extended to another surface making an effective barrier

Videos

How The Standard Air Blade® Air Knife Works

Compressed air enters the air knife at the rear (or end) ports at (A). Air is entrained at point (B) by the compressed air stream that leaves the air knife from a small gap. The entrained air follows the Coanda profile and along the front face (C) that directs the airflow in a perfect straight line at 90 degrees to create a uniform sheet of air along the entire length of the Air Blade TM air knife at it leaves the air knife at point (D). The amplified air stream maximized velocity and force are maximized as a well-defined sheet of laminar flow with minimal wind shear for reduced energy use in the blow off and cooling.

Offered in aluminum or stainless steel and can be manufactured in any length from a combination of our standard sizes.

Performance

NOTE: Force and Velocity at 6″(152mm) from target.

Sound Level 78 dBA at 80 PSIG (5.5 BAR) for Standard Air Blade® Air Knives

| 10003 / 10003S – 3″ Standard Air Blade® Air Knives | ||||||||||||

| Inlet Pressure (PSIG) | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 110 | 120 |

| Force (lbs)* | 0.005 | 0.04 | 0.1 | 0.18 | 0.28 | 0.4 | 0.53 | 0.69 | 0.86 | 1.06 | 1.26 | 1.51 |

| Air Consumption (SCFM) | 0.6 | 1.7 | 3.7 | 6 | 9.1 | 12 | 16 | 20 | 24 | 29 | 34 | 39 |

| Velocity (ft/s)* | 26 | 40.6 | 54.7 | 68.4 | 80.9 | 93.5 | 105 | 117 | 128 | 139 | 149 | 158 |

| Inlet Pressure (BAR) | 0.7 | 1.4 | 2.1 | 2.8 | 3.5 | 4.2 | 4.9 | 5.6 | 6.2 | 6.9 | 7.7 | 8.4 |

| Force (grams)* | 2.18 | 19.6 | 45.7 | 83 | 126 | 181 | 242 | 314 | 392 | 481 | 573 | 684 |

| Air Consumption (SLPM) | 16.6 | 47.9 | 105 | 171 | 258 | 350 | 442 | 571 | 681 | 810 | 957 | 1104 |

| Velocity (m/s)* | 7.9 | 12.4 | 16.7 | 20.8 | 24.7 | 28.5 | 32.1 | 35.8 | 39.1 | 42.2 | 45.3 | 48.1 |

| 10006 / 10006S – 6″ Standard Air Blade® Air Knives | ||||||||||||

| Inlet Pressure (PSIG) | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 110 | 120 |

| Force (lbs)* | 0.01 | 0.05 | 0.13 | 0.24 | 0.35 | 0.49 | 0.65 | 0.83 | 1.02 | 1.23 | 1.46 | 1.72 |

| Air Consumption (SCFM) | 1.6 | 3.6 | 6.1 | 9.1 | 12 | 16 | 20 | 24 | 29 | 34 | 40 | 46 |

| Velocity (ft/s)* | 5.1 | 14.1 | 22.6 | 30.6 | 38.1 | 45.1 | 52 | 58 | 63 | 68 | 72 | 76 |

| Inlet Pressure (BAR) | 0.7 | 1.4 | 2.1 | 2.8 | 3.5 | 4.2 | 4.9 | 5.6 | 6.2 | 6.9 | 7.7 | 8.4 |

| Force (grams)* | 4.35 | 23.9 | 61 | 107 | 159 | 222 | 294 | 374 | 462 | 560 | 664 | 779 |

| Air Consumption (SLPM) | 44.2 | 103.1 | 173 | 258 | 350 | 442 | 552 | 681 | 828 | 976 | 1123 | 1288 |

| Velocity (m/s)* | 1.5 | 4.3 | 6.9 | 9.3 | 11.6 | 13.7 | 15.7 | 17.5 | 19.1 | 20.7 | 22.1 | 23.3 |

| 10008 / 10008S – 8″ Standard Air Blade® Air Knives | ||||||||||||

| Inlet Pressure (PSIG) | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 110 | 120 |

| Force (lbs)* | 0.01 | 0.06 | 0.16 | 0.27 | 0.4 | 0.55 | 0.72 | 0.92 | 1.12 | 1.35 | 1.6 | 1.87 |

| Air Consumption (SCFM) | 2.5 | 4.9 | 7.8 | 11 | 14 | 18 | 23 | 27 | 33 | 38 | 44 | 50 |

| Velocity (ft/s)* | 4.7 | 12.3 | 19.5 | 26.1 | 32.2 | 37.8 | 42.9 | 47.4 | 51.5 | 55.1 | 58.1 | 60.4 |

| Inlet Pressure (BAR) | 0.7 | 1.4 | 2.1 | 2.8 | 3.5 | 4.2 | 4.9 | 5.6 | 6.2 | 6.9 | 7.7 | 8.4 |

| Force (grams)* | 4.35 | 28.3 | 71.8 | 122 | 183 | 250 | 329 | 416 | 509 | 612 | 726 | 847 |

| Air Consumption (SLPM) | 71.8 | 140 | 221 | 313 | 405 | 515 | 644 | 773 | 920 | 1068 | 1233 | 1417 |

| Velocity (m/s)* | 1.4 | 3.8 | 5.9 | 8 | 9.8 | 11.5 | 13.1 | 14.5 | 15.7 | 16.8 | 17.7 | 18.4 |

| 10012 / 10012S – 12″ Standard Air Blade® Air Knives | ||||||||||||

| Inlet Pressure (PSIG) | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 110 | 120 |

| Force (lbs)* | 0 | 0.1 | 0.22 | 0.36 | 0.52 | 0.7 | 0.89 | 1.11 | 1.34 | 1.6 | 1.87 | 2.16 |

| Air Consumption (SCFM) | 4.6 | 7.2 | 11.1 | 14 | 19 | 23 | 28 | 33 | 39 | 46 | 52 | 59 |

| Velocity (ft/s)* | 6.3 | 12.5 | 18.3 | 23.5 | 28.3 | 32.5 | 36.1 | 39.3 | 42 | 44.2 | 45.8 | 47 |

| Inlet Pressure (BAR) | 0.7 | 1.4 | 2.1 | 2.8 | 3.5 | 4.2 | 4.9 | 5.6 | 6.2 | 6.9 | 7.7 | 8.4 |

| Force (grams)* | 2.18 | 43.5 | 100 | 163 | 235 | 316 | 405 | 503 | 610 | 725 | 849 | 982 |

| Air Consumption (SLPM) | 128.8 | 202 | 313 | 405 | 534 | 663 | 791 | 939 | 1104 | 1288 | 1472 | 1657 |

| Velocity (m/s)* | 1.9 | 3.8 | 5.6 | 7.2 | 8.6 | 9.9 | 11 | 12 | 12.8 | 13.5 | 14 | 14.3 |

| 10018 / 10018S – 18″ Standard Air Blade® Air Knives | ||||||||||||

| Inlet Pressure (PSIG) | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 110 | 120 |

| Force (lbs)* | 0.03 | 0.17 | 0.32 | 0.51 | 0.72 | 0.93 | 1.17 | 1.43 | 1.7 | 2 | 2.31 | 2.64 |

| Air Consumption (SCFM) | 7.2 | 11 | 16 | 20 | 25 | 31 | 36 | 43 | 49 | 57 | 64 | 72 |

| Velocity (ft/s)* | 8.4 | 13.7 | 18.6 | 22.9 | 26.7 | 30 | 32.8 | 35 | 36.8 | 38 | 38.8 | 38.9 |

| Inlet Pressure (BAR) | 0.7 | 1.4 | 2.1 | 2.8 | 3.5 | 4.2 | 4.9 | 5.6 | 6.2 | 6.9 | 7.7 | 8.4 |

| Force (grams)* | 15.24 | 78.4 | 146 | 233 | 324 | 422 | 531 | 647 | 773 | 906 | 1049 | 1197 |

| Air Consumption (SLPM) | 202 | 313 | 442 | 571 | 718 | 865 | 1031 | 1215 | 1399 | 1601 | 1804 | 2025 |

| Velocity (m/s)* | 2.6 | 4.2 | 5.7 | 7 | 8.1 | 9.1 | 10 | 10.7 | 11.2 | 11.6 | 11.8 | 11.9 |

| 10024 / 10024S – 24″ Standard Air Blade® Air Knives | ||||||||||||

| Inlet Pressure (PSIG) | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 110 | 120 |

| Force (lbs)* | 0.1 | 0.28 | 0.48 | 0.7 | 0.94 | 1.2 | 1.48 | 1.78 | 2.09 | 2.43 | 2.78 | 3.16 |

| Air Consumption (SCFM) | 10 | 15 | 20 | 26 | 32 | 38 | 45 | 52 | 59 | 67 | 75 | 84 |

| Velocity (ft/s)* | 9.8 | 14.6 | 19 | 22.9 | 26.2 | 29.1 | 31.4 | 33.2 | 34.5 | 35.3 | 35.5 | 35.3 |

| Inlet Pressure (BAR) | 0.7 | 1.4 | 2.1 | 2.8 | 3.5 | 4.2 | 4.9 | 5.6 | 6.2 | 6.9 | 7.7 | 8.4 |

| Force (grams)* | 45.72 | 128.5 | 220 | 318 | 427 | 544 | 671 | 806 | 949 | 1102 | 1263 | 1433 |

| Air Consumption (SLPM) | 294 | 423 | 571 | 736 | 902 | 1068 | 1270 | 1472 | 1675 | 1896 | 2135 | 2374 |

| Velocity (m/s)* | 3 | 4.5 | 5.8 | 7 | 8 | 8.9 | 9.6 | 10.1 | 10.5 | 10.8 | 10.8 | 10.8 |

| 10030 / 10030S – 30″ Standard Air Blade® Air Knives | ||||||||||||

| Inlet Pressure (PSIG) | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 110 | 120 |

| Force (lbs)* | 0.2 | 0.42 | 0.66 | 0.92 | 1.2 | 1.5 | 1.81 | 2.16 | 2.52 | 2.89 | 3.28 | 3.7 |

| Air Consumption (SCFM) | 14 | 19 | 25 | 31 | 38 | 46 | 53 | 61 | 70 | 78 | 87 | 97 |

| Velocity (ft/s)* | 10.7 | 15.3 | 19.4 | 23 | 26 | 28.6 | 30.7 | 32.2 | 33.2 | 33.7 | 33.7 | 33.2 |

| Inlet Pressure (BAR) | 0.7 | 1.4 | 2.1 | 2.8 | 3.5 | 4.2 | 4.9 | 5.6 | 6.2 | 6.9 | 7.7 | 8.4 |

| Force (grams)* | 89.27 | 189.4 | 300 | 418 | 544 | 681 | 823 | 978 | 1141 | 1311 | 1489 | 1676 |

| Air Consumption (SLPM) | 387 | 534 | 699 | 883 | 1086 | 1288 | 1491 | 1730 | 1969 | 2209 | 2466 | 2742 |

| Velocity (m/s)* | 3.3 | 4.7 | 5.9 | 7 | 7.9 | 8.7 | 9.3 | 9.8 | 10.1 | 10.3 | 10.3 | 10.1 |

| 10036 / 10036S – 36″ Standard Air Blade® Air Knives | ||||||||||||

| Inlet Pressure (PSIG) | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 110 | 120 |

| Force (lbs)* | 0.33 | 0.59 | 0.87 | 1.17 | 1.49 | 1.83 | 2.19 | 2.57 | 2.97 | 3.38 | 3.82 | 4.27 |

| Air Consumption (SCFM) | 16 | 23 | 29 | 37 | 44 | 53 | 61 | 70 | 79 | 89 | 99 | 109 |

| Velocity (ft/s)* | 11.4 | 15.8 | 19.7 | 23.1 | 26 | 28.4 | 30.2 | 31.6 | 32.4 | 32.7 | 32.5 | 31.8 |

| Inlet Pressure (BAR) | 0.7 | 1.4 | 2.1 | 2.8 | 3.5 | 4.2 | 4.9 | 5.6 | 6.2 | 6.9 | 7.7 | 8.4 |

| Force (grams)* | 148.05 | 265.6 | 394 | 531 | 677 | 830 | 993 | 1165 | 1346 | 1533 | 1731 | 1938 |

| Air Consumption (SLPM) | 460 | 644 | 828 | 1049 | 1252 | 1491 | 1730 | 1988 | 2246 | 2522 | 2816 | 3092 |

| Velocity (m/s)* | 3.5 | 4.8 | 6 | 7.1 | 7.9 | 8.7 | 9.2 | 9.6 | 9.9 | 10 | 9.9 | 9.7 |

NOTE: Force and Velocity at 6″(152mm) from target.

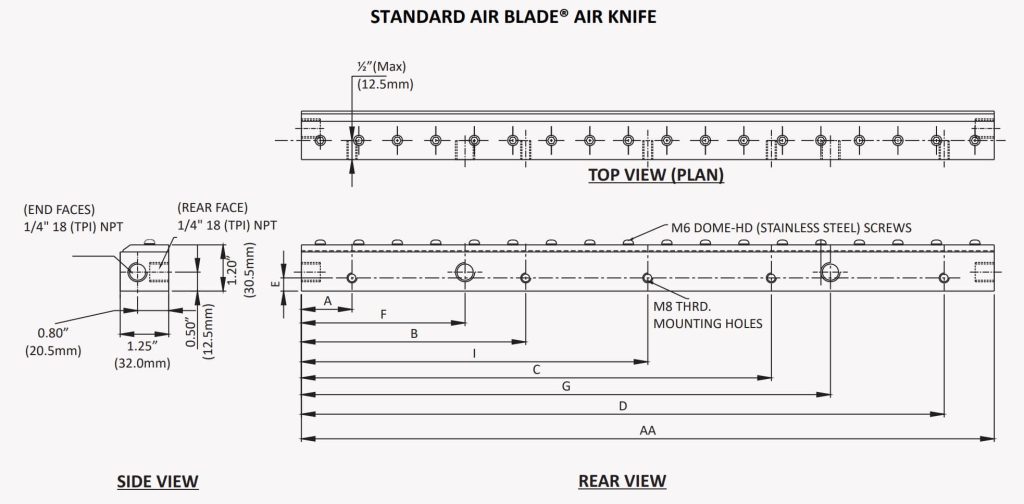

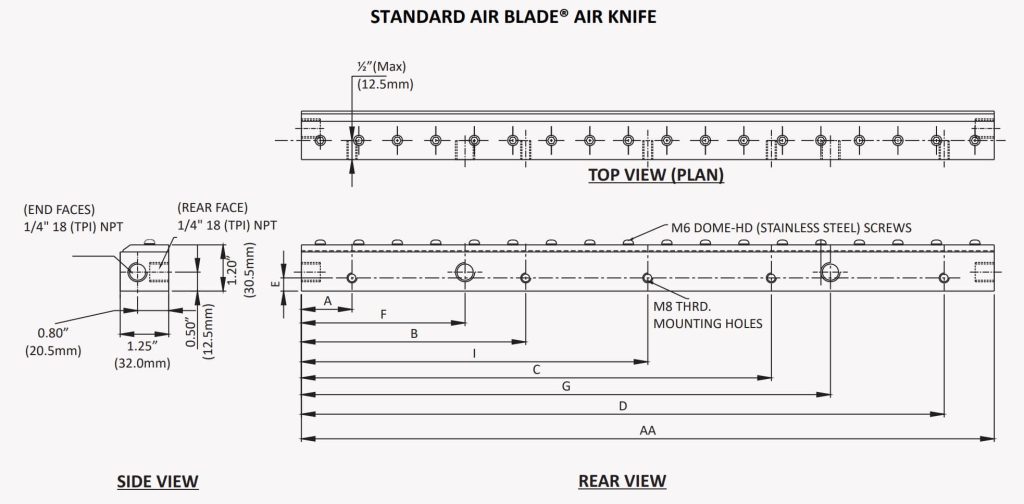

Dimensions

The Standard Air-Blade® Air Knife is available in eight standard lengths: 3″ (76mm) , 6″ (150mm) , 8″ (203mm), 12″ (300mm), 18″ (457mm), 24″ (609.5mm), 30″ (761mm), 36″ (914mm)

Special lengths of our Air-Blade® are available on special order including lengths combining several units.

| PART NO. (Aluminium & Stainless Steel) | AA | A | B | C | D | E | F # of Rear Inlets | G # of Side Inlets |

|---|---|---|---|---|---|---|---|---|

| Model 10003 Model 10003S | 3″ 76mm | 0.6″ 16mm | – – | – – | 2.4″ 60mm | 0.3″ 8mm | 1 | 2 |

| Model 10006 Model 10006S | 6″ 150mm | 1.2″ 30mm | – – | – – | 4.7″ 120mm | 0.3″ 8mm | 1 | 2 |

| Model 10008 | 8″ 203mm | 1.2″ 30mm | – – | – – | 6.8″ 173mm | 0.3″ 8mm | 1 | 2 |

| Model 10012 Model 10012S | 12″ 300mm | 1.0″ 25mm | 3.1″ 8.0mm | 8.7″ 220mm | 10.8″ 275mm | 0.3″ 8mm | 1 | 2 |

| Model 10018 Model 10018S | 18″ 457mm | 1.3″ 33.5mm | 5.8″ 148.5mm | 12.1″ 308.5mm | 16.7″ 423.5mm | 0.3″ 8mm | 2 | 2 |

| Model 10024 Model 10024S | 24″ 609.5mm | 1.3″ 33.5mm | 8.9″ 225mm | 15.2″ 385mm | 16.7″ 423.5mm | 0.3″ 8mm | 2 | 2 |

| Model 10030 Model 10030S | 30″ 761mm | 1.4″ 35mm | 8.9″ 227mm | 19.1″ 485mm | 28.6″ 727mm | 0.3″ 8mm | 2 | 2 |

| Model 10036 Model 10036S | 36″ 914mm | 1.4″ 35mm | 8.9″ 227mm | 27.1″ 684mm | 34.6″ 879mm | 0.3″ 8mm | 2 | 2 |

(Extra Middle mounting hole only on the 36″ Air-Blade® 457mm from each end)

Air-Blade® comes with a standard machined .002″ outlet gap which will work for 90% of all applications encountered. If greater force is required, a .002″ shim may be installed to open the gap for greater flow. Constructed in either coated Aluminium or Stainless Steel.

| Effective Length | Model Number | Materials Of Construction |

|---|---|---|

| 3″ | 10003 | Aluminium |

| 3″ | 10003S | Stainless Steel |

| 6″ | 10006 | Aluminium |

| 6″ | 10006S | Stainless Steel |

| 8″ | 10008 | Aluminium |

| 12″ | 10012 | Aluminium |

| 12″ | 10012S | Stainless Steel |

| 18″ | 10018 | Aluminium |

| 18″ | 10018S | Stainless Steel |

| 24″ | 10024 | Aluminium |

| 24″ | 10024S | Stainless Steel |

| 30″ | 10030 | Aluminium |

| 30″ | 10030S | Stainless Steel |

| 36″ | 10036 | Aluminium |

| 36″ | 10036S | Stainless Steel |

| Stainless Steel Air Blades™ Air Knives | |||

|---|---|---|---|

| PART NO. | DESCRIPTION | SIZE | PRICE US DOLLARS |

| 10003S | Stainless Steel Standard Air Blade Only | 3″ | $268.00 |

| 10006S | Stainless Steel Standard Air Blade Only | 6″ | $310.00 |

| 10008S | Stainless Steel Standard Air Blade Only | 8″ | $385.00 |

| 10012S | Stainless Steel Standard Air Blade Only | 12″ | $466.00 |

| 10018S | Stainless Steel Standard Air Blade Only | 18″ | $642.00 |

| 10024S | Stainless Steel Standard Air Blade Only | 24″ | $730.00 |

| 10030S | Stainless Steel Standard Air Blade Only | 30″ | $950.00 |

| 10036S | Stainless Steel Standard Air Blade Only | 36″ | $1,096.00 |

| 11003S | Stainless Steel Standard Air Blade + Filter Model 90004 | 3″ | $393.00 |

| 11006S | Stainless Steel Standard Air Blade + Filter Model 90004 | 6″ | $435.00 |

| 11008S | Stainless Steel Standard Air Blade + Filter Model 90004 | 8″ | $510.00 |

| 11012S | Stainless Steel Standard Air Blade + Filter Model 90004 | 12″ | $591.00 |

| 11018S | Stainless Steel Standard Air Blade + Filter Model 90001 | 18″ | $767.00 |

| 11024S | Stainless Steel Standard Air Blade + Filter Model 90001 | 24″ | $855.00 |

| 11030S | Stainless Steel Standard Air Blade + Filter Model 90002 | 30″ | $1,175.00 |

| 11036S | Stainless Steel Standard Air Blade + Filter Model 90002 | 36″ | $1,321.00 |

| 12003S | Stainless Steel Standard Air Blade + Filter Model 90004 + Regulator Model 90008 | 3″ | $468.00 |

| 12006S | Stainless Steel Standard Air Blade + Filter Model 90004 + Regulator Model 90008 | 6″ | $510.00 |

| 12008S | Stainless Steel Standard Air Blade + Filter Model 90004 + Regulator Model 90008 | 8″ | $585.00 |

| 12012S | Stainless Steel Standard Air Blade + Filter Model 90004 + Regulator Model 90008 | 12″ | $666.00 |

| 12018S | Stainless Steel Standard Air Blade + Filter Model 90001 + Regulator Model 90008 | 18″ | $842.00 |

| 12024S | Stainless Steel Standard Air Blade + Filter Model 90001 + Regulator Model 90009 | 24″ | $965.00 |

| 12030S | Stainless Steel Standard Air Blade + Filter Model 90002 + Regulator Model 90009 | 30″ | $1,285.00 |

| 12036S | Stainless Steel Standard Air Blade + Filter Model 90002 + Regulator Model 90009 | 36″ | $1,431.00 |

| More Information or Buy Here |

- Overview

-

Product Overview

Stainless Steel Standard Air Blade Air Knife

The Standard Stainless Steel Air Knife from Nex Flow® is easy to install and maintain. It can reduce both compressed air consumption and noise levels. used to blow off liquid or debris from products as they travel on conveyors.

Built and designed for significantly longer life in difficult environments than many competing products. Flexible mounting options and easy to fit in small spaces. Energy reduction in compressed air use up to 90% and noise reductions of 10 dbA. Maintenance free with output easily controlled, safe to use.

Stainless Steel Standard Air Blade Air Knife produces a “laminar” flow of air using the Coanda effect. This draws a large volume of air from the surrounding area along with the small amount of compressed air from the Air-Blade. It also produces an output flow up to 30 times.

- Advantages

-

Features / Advantages

- Quiet – 72 dBA for most applications

- Uniform airflow across entire length

- Minimal Air Consumption

- Variable force and flow

- No moving parts – maintenance free

- Easy mounting

- Compact, rugged, easy to install

- Stainless steel screws in all models

- 30:1 air amplification

- Anodized Aluminum to protect the surface of aluminum versions

- Stainless Steel shim

- 303/304 stainless steel for high temperature and corrosive environments

- Surface entraining the air can be extended to another surface making an effective barrier

- Videos

-

Videos

How The Standard Air Blade® Air Knife Works

Compressed air enters the air knife at the rear (or end) ports at (A). Air is entrained at point (B) by the compressed air stream that leaves the air knife from a small gap. The entrained air follows the Coanda profile and along the front face (C) that directs the airflow in a perfect straight line at 90 degrees to create a uniform sheet of air along the entire length of the Air Blade TM air knife at it leaves the air knife at point (D). The amplified air stream maximized velocity and force are maximized as a well-defined sheet of laminar flow with minimal wind shear for reduced energy use in the blow off and cooling.

Offered in aluminum or stainless steel and can be manufactured in any length from a combination of our standard sizes.

- Performance

-

Performance

NOTE: Force and Velocity at 6″(152mm) from target.

Sound Level 78 dBA at 80 PSIG (5.5 BAR) for Standard Air Blade® Air Knives

10003 / 10003S – 3″ Standard Air Blade® Air Knives Inlet Pressure (PSIG) 10 20 30 40 50 60 70 80 90 100 110 120 Force (lbs)* 0.005 0.04 0.1 0.18 0.28 0.4 0.53 0.69 0.86 1.06 1.26 1.51 Air Consumption (SCFM) 0.6 1.7 3.7 6 9.1 12 16 20 24 29 34 39 Velocity (ft/s)* 26 40.6 54.7 68.4 80.9 93.5 105 117 128 139 149 158 Inlet Pressure (BAR) 0.7 1.4 2.1 2.8 3.5 4.2 4.9 5.6 6.2 6.9 7.7 8.4 Force (grams)* 2.18 19.6 45.7 83 126 181 242 314 392 481 573 684 Air Consumption (SLPM) 16.6 47.9 105 171 258 350 442 571 681 810 957 1104 Velocity (m/s)* 7.9 12.4 16.7 20.8 24.7 28.5 32.1 35.8 39.1 42.2 45.3 48.1 10006 / 10006S – 6″ Standard Air Blade® Air Knives Inlet Pressure (PSIG) 10 20 30 40 50 60 70 80 90 100 110 120 Force (lbs)* 0.01 0.05 0.13 0.24 0.35 0.49 0.65 0.83 1.02 1.23 1.46 1.72 Air Consumption (SCFM) 1.6 3.6 6.1 9.1 12 16 20 24 29 34 40 46 Velocity (ft/s)* 5.1 14.1 22.6 30.6 38.1 45.1 52 58 63 68 72 76 Inlet Pressure (BAR) 0.7 1.4 2.1 2.8 3.5 4.2 4.9 5.6 6.2 6.9 7.7 8.4 Force (grams)* 4.35 23.9 61 107 159 222 294 374 462 560 664 779 Air Consumption (SLPM) 44.2 103.1 173 258 350 442 552 681 828 976 1123 1288 Velocity (m/s)* 1.5 4.3 6.9 9.3 11.6 13.7 15.7 17.5 19.1 20.7 22.1 23.3 10008 / 10008S – 8″ Standard Air Blade® Air Knives Inlet Pressure (PSIG) 10 20 30 40 50 60 70 80 90 100 110 120 Force (lbs)* 0.01 0.06 0.16 0.27 0.4 0.55 0.72 0.92 1.12 1.35 1.6 1.87 Air Consumption (SCFM) 2.5 4.9 7.8 11 14 18 23 27 33 38 44 50 Velocity (ft/s)* 4.7 12.3 19.5 26.1 32.2 37.8 42.9 47.4 51.5 55.1 58.1 60.4 Inlet Pressure (BAR) 0.7 1.4 2.1 2.8 3.5 4.2 4.9 5.6 6.2 6.9 7.7 8.4 Force (grams)* 4.35 28.3 71.8 122 183 250 329 416 509 612 726 847 Air Consumption (SLPM) 71.8 140 221 313 405 515 644 773 920 1068 1233 1417 Velocity (m/s)* 1.4 3.8 5.9 8 9.8 11.5 13.1 14.5 15.7 16.8 17.7 18.4 10012 / 10012S – 12″ Standard Air Blade® Air Knives Inlet Pressure (PSIG) 10 20 30 40 50 60 70 80 90 100 110 120 Force (lbs)* 0 0.1 0.22 0.36 0.52 0.7 0.89 1.11 1.34 1.6 1.87 2.16 Air Consumption (SCFM) 4.6 7.2 11.1 14 19 23 28 33 39 46 52 59 Velocity (ft/s)* 6.3 12.5 18.3 23.5 28.3 32.5 36.1 39.3 42 44.2 45.8 47 Inlet Pressure (BAR) 0.7 1.4 2.1 2.8 3.5 4.2 4.9 5.6 6.2 6.9 7.7 8.4 Force (grams)* 2.18 43.5 100 163 235 316 405 503 610 725 849 982 Air Consumption (SLPM) 128.8 202 313 405 534 663 791 939 1104 1288 1472 1657 Velocity (m/s)* 1.9 3.8 5.6 7.2 8.6 9.9 11 12 12.8 13.5 14 14.3 10018 / 10018S – 18″ Standard Air Blade® Air Knives Inlet Pressure (PSIG) 10 20 30 40 50 60 70 80 90 100 110 120 Force (lbs)* 0.03 0.17 0.32 0.51 0.72 0.93 1.17 1.43 1.7 2 2.31 2.64 Air Consumption (SCFM) 7.2 11 16 20 25 31 36 43 49 57 64 72 Velocity (ft/s)* 8.4 13.7 18.6 22.9 26.7 30 32.8 35 36.8 38 38.8 38.9 Inlet Pressure (BAR) 0.7 1.4 2.1 2.8 3.5 4.2 4.9 5.6 6.2 6.9 7.7 8.4 Force (grams)* 15.24 78.4 146 233 324 422 531 647 773 906 1049 1197 Air Consumption (SLPM) 202 313 442 571 718 865 1031 1215 1399 1601 1804 2025 Velocity (m/s)* 2.6 4.2 5.7 7 8.1 9.1 10 10.7 11.2 11.6 11.8 11.9 10024 / 10024S – 24″ Standard Air Blade® Air Knives Inlet Pressure (PSIG) 10 20 30 40 50 60 70 80 90 100 110 120 Force (lbs)* 0.1 0.28 0.48 0.7 0.94 1.2 1.48 1.78 2.09 2.43 2.78 3.16 Air Consumption (SCFM) 10 15 20 26 32 38 45 52 59 67 75 84 Velocity (ft/s)* 9.8 14.6 19 22.9 26.2 29.1 31.4 33.2 34.5 35.3 35.5 35.3 Inlet Pressure (BAR) 0.7 1.4 2.1 2.8 3.5 4.2 4.9 5.6 6.2 6.9 7.7 8.4 Force (grams)* 45.72 128.5 220 318 427 544 671 806 949 1102 1263 1433 Air Consumption (SLPM) 294 423 571 736 902 1068 1270 1472 1675 1896 2135 2374 Velocity (m/s)* 3 4.5 5.8 7 8 8.9 9.6 10.1 10.5 10.8 10.8 10.8 10030 / 10030S – 30″ Standard Air Blade® Air Knives Inlet Pressure (PSIG) 10 20 30 40 50 60 70 80 90 100 110 120 Force (lbs)* 0.2 0.42 0.66 0.92 1.2 1.5 1.81 2.16 2.52 2.89 3.28 3.7 Air Consumption (SCFM) 14 19 25 31 38 46 53 61 70 78 87 97 Velocity (ft/s)* 10.7 15.3 19.4 23 26 28.6 30.7 32.2 33.2 33.7 33.7 33.2 Inlet Pressure (BAR) 0.7 1.4 2.1 2.8 3.5 4.2 4.9 5.6 6.2 6.9 7.7 8.4 Force (grams)* 89.27 189.4 300 418 544 681 823 978 1141 1311 1489 1676 Air Consumption (SLPM) 387 534 699 883 1086 1288 1491 1730 1969 2209 2466 2742 Velocity (m/s)* 3.3 4.7 5.9 7 7.9 8.7 9.3 9.8 10.1 10.3 10.3 10.1 10036 / 10036S – 36″ Standard Air Blade® Air Knives Inlet Pressure (PSIG) 10 20 30 40 50 60 70 80 90 100 110 120 Force (lbs)* 0.33 0.59 0.87 1.17 1.49 1.83 2.19 2.57 2.97 3.38 3.82 4.27 Air Consumption (SCFM) 16 23 29 37 44 53 61 70 79 89 99 109 Velocity (ft/s)* 11.4 15.8 19.7 23.1 26 28.4 30.2 31.6 32.4 32.7 32.5 31.8 Inlet Pressure (BAR) 0.7 1.4 2.1 2.8 3.5 4.2 4.9 5.6 6.2 6.9 7.7 8.4 Force (grams)* 148.05 265.6 394 531 677 830 993 1165 1346 1533 1731 1938 Air Consumption (SLPM) 460 644 828 1049 1252 1491 1730 1988 2246 2522 2816 3092 Velocity (m/s)* 3.5 4.8 6 7.1 7.9 8.7 9.2 9.6 9.9 10 9.9 9.7 NOTE: Force and Velocity at 6″(152mm) from target.

- Dimensions

-

Dimensions

The Standard Air-Blade® Air Knife is available in eight standard lengths: 3″ (76mm) , 6″ (150mm) , 8″ (203mm), 12″ (300mm), 18″ (457mm), 24″ (609.5mm), 30″ (761mm), 36″ (914mm)

Special lengths of our Air-Blade® are available on special order including lengths combining several units.

PART NO. (Aluminium & Stainless Steel) AA A B C D E F # of Rear Inlets G # of Side Inlets Model 10003 Model 10003S 3″ 76mm 0.6″ 16mm – – – – 2.4″ 60mm 0.3″ 8mm 1 2 Model 10006 Model 10006S 6″ 150mm 1.2″ 30mm – – – – 4.7″ 120mm 0.3″ 8mm 1 2 Model 10008 8″ 203mm 1.2″ 30mm – – – – 6.8″ 173mm 0.3″ 8mm 1 2 Model 10012 Model 10012S 12″ 300mm 1.0″ 25mm 3.1″ 8.0mm 8.7″ 220mm 10.8″ 275mm 0.3″ 8mm 1 2 Model 10018 Model 10018S 18″ 457mm 1.3″ 33.5mm 5.8″ 148.5mm 12.1″ 308.5mm 16.7″ 423.5mm 0.3″ 8mm 2 2 Model 10024 Model 10024S 24″ 609.5mm 1.3″ 33.5mm 8.9″ 225mm 15.2″ 385mm 16.7″ 423.5mm 0.3″ 8mm 2 2 Model 10030 Model 10030S 30″ 761mm 1.4″ 35mm 8.9″ 227mm 19.1″ 485mm 28.6″ 727mm 0.3″ 8mm 2 2 Model 10036 Model 10036S 36″ 914mm 1.4″ 35mm 8.9″ 227mm 27.1″ 684mm 34.6″ 879mm 0.3″ 8mm 2 2 (Extra Middle mounting hole only on the 36″ Air-Blade® 457mm from each end)

Air-Blade® comes with a standard machined .002″ outlet gap which will work for 90% of all applications encountered. If greater force is required, a .002″ shim may be installed to open the gap for greater flow. Constructed in either coated Aluminium or Stainless Steel.

Effective Length Model Number Materials Of Construction 3″ 10003 Aluminium 3″ 10003S Stainless Steel 6″ 10006 Aluminium 6″ 10006S Stainless Steel 8″ 10008 Aluminium 12″ 10012 Aluminium 12″ 10012S Stainless Steel 18″ 10018 Aluminium 18″ 10018S Stainless Steel 24″ 10024 Aluminium 24″ 10024S Stainless Steel 30″ 10030 Aluminium 30″ 10030S Stainless Steel 36″ 10036 Aluminium 36″ 10036S Stainless Steel - Pricing

-

Stainless Steel Air Blades™ Air Knives PART NO. DESCRIPTION SIZE PRICE US DOLLARS 10003S Stainless Steel Standard Air Blade Only 3″ $268.00 10006S Stainless Steel Standard Air Blade Only 6″ $310.00 10008S Stainless Steel Standard Air Blade Only 8″ $385.00 10012S Stainless Steel Standard Air Blade Only 12″ $466.00 10018S Stainless Steel Standard Air Blade Only 18″ $642.00 10024S Stainless Steel Standard Air Blade Only 24″ $730.00 10030S Stainless Steel Standard Air Blade Only 30″ $950.00 10036S Stainless Steel Standard Air Blade Only 36″ $1,096.00 11003S Stainless Steel Standard Air Blade + Filter Model 90004 3″ $393.00 11006S Stainless Steel Standard Air Blade + Filter Model 90004 6″ $435.00 11008S Stainless Steel Standard Air Blade + Filter Model 90004 8″ $510.00 11012S Stainless Steel Standard Air Blade + Filter Model 90004 12″ $591.00 11018S Stainless Steel Standard Air Blade + Filter Model 90001 18″ $767.00 11024S Stainless Steel Standard Air Blade + Filter Model 90001 24″ $855.00 11030S Stainless Steel Standard Air Blade + Filter Model 90002 30″ $1,175.00 11036S Stainless Steel Standard Air Blade + Filter Model 90002 36″ $1,321.00 12003S Stainless Steel Standard Air Blade + Filter Model 90004 + Regulator Model 90008 3″ $468.00 12006S Stainless Steel Standard Air Blade + Filter Model 90004 + Regulator Model 90008 6″ $510.00 12008S Stainless Steel Standard Air Blade + Filter Model 90004 + Regulator Model 90008 8″ $585.00 12012S Stainless Steel Standard Air Blade + Filter Model 90004 + Regulator Model 90008 12″ $666.00 12018S Stainless Steel Standard Air Blade + Filter Model 90001 + Regulator Model 90008 18″ $842.00 12024S Stainless Steel Standard Air Blade + Filter Model 90001 + Regulator Model 90009 24″ $965.00 12030S Stainless Steel Standard Air Blade + Filter Model 90002 + Regulator Model 90009 30″ $1,285.00 12036S Stainless Steel Standard Air Blade + Filter Model 90002 + Regulator Model 90009 36″ $1,431.00 More Information or Buy Here