Product Overview

The Silent Frigid-X® Panel Cooler series for electronic control panels provide a low cost method of both purging and cooling electrical and electronic control panels by using a stainless steel vortex tube to create cold air from ordinary compressed air. By Utilizing a hot and cold end muffling kit the unit is made extra quiet to under 64 dBA depending on capacity. The hot end muffler also acts as a “heat guard” – you can wrap your hand around it without feeling much heat. The hot air is exhausted safely underneath the hot end muffler.

The panel cooler series are compact and can be installed in minutes through a standard electrical knockout. There are virtually no moving parts.

* US patent number 8,616,010 / Other countries: Patented or Patent Pending *

Note: Always question non-approved units used on electrical enclosures to ensure that your panels are not damaged by inferior products.

You can use our online panel cooler calculator,

or, If you would like us to do the calculation for you, or purchase consultation and we will followup with you.

If you have any questions please email: support@nexflow.com

Features / Advantages

- Low cost

- Compact

- No CFCs

- Fast installation

- Stabilize enclosure temperature and humidity

- Virtually maintenance free (No Moving Parts)

- Mounts in a standard electrical knockout

- Stops heat damage and nuisance tripping

- Eliminates fans and filters

- Prevents dirt contamination by keeping enclosure at positive pressure

- Units applicable to all environments including high temperature to 200ºF

Videos

How The Silent Frigid X Cabinet Enclosure Cooler Works

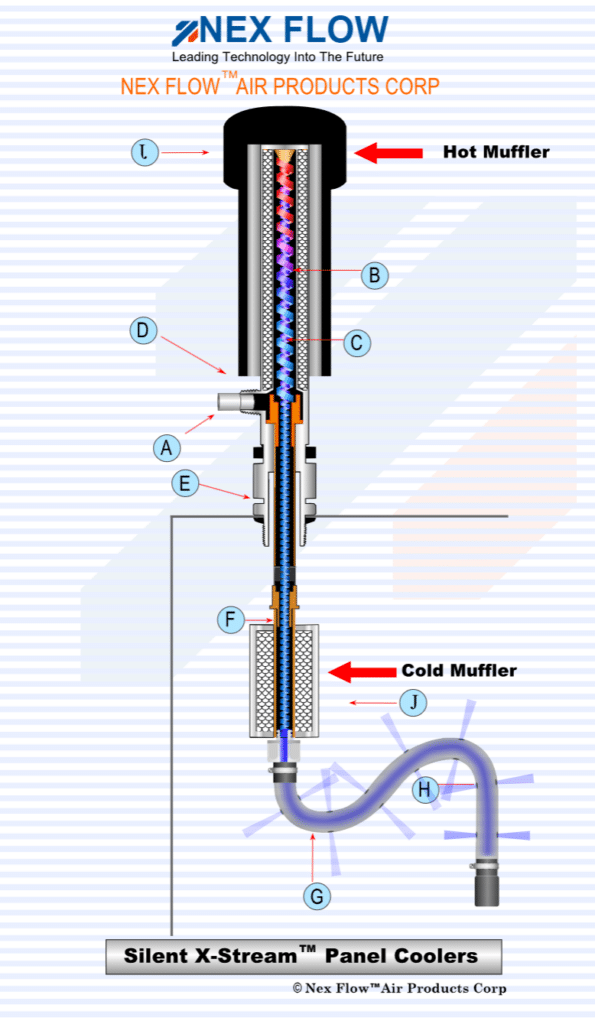

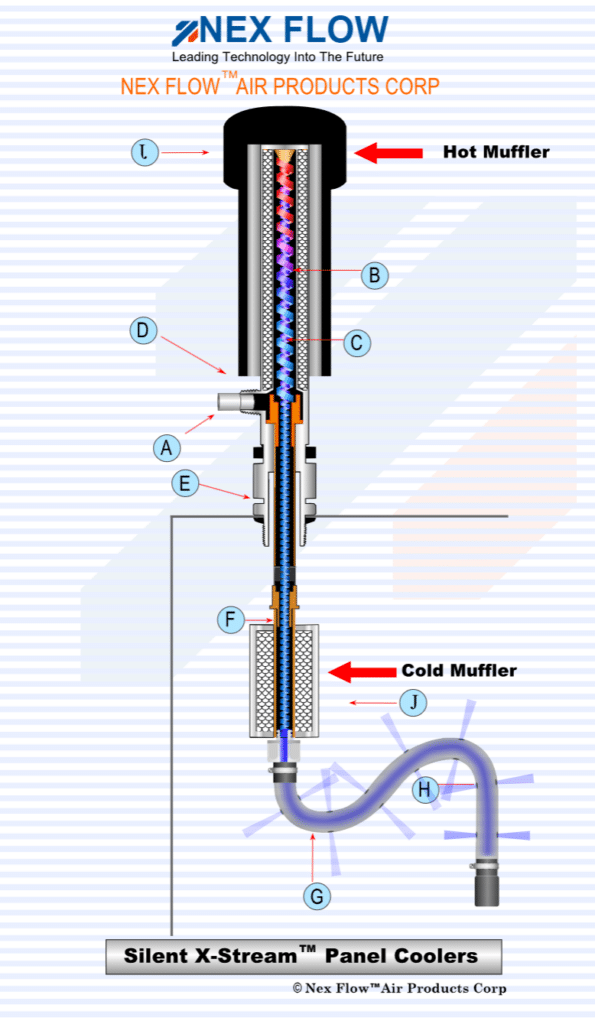

The regular Frigid-X® Panel Coolers are under 78 dBA for noise level but in some instances it is not enough and a quieter version is necessary. This is where the Silent X-Stream® Panel Cooler can be utilized. It can reduce noise levels to 65 dBA It works the same way as a regular Panel Cooler where compressed air enters at point (A) into the vortex tube component of the panel cooler. The vortex tube creates two streams of compressed air – a hot stream at (B) and a cold stream at (C). The hot air stream from the vortex tube is vented outside the system at (D) after internal muffling. An additional Hot End muffler (I) reduces the noise further and also acts a protection cover over the hot end should anyone try to grab the unit. Hot air from inside the control panel is vented at point (E) to the outside. Cold air goes into the control panel at (F) into an additional cold end muffler (J) and then into the cold distribution hose (G). Holes (H) are punched into the hose kit to distribute the cold air inside the panel. A muffler (I) further reduces the noise level of the exhausting at the end of the hose.

Silent Frigid X Panel Cooler

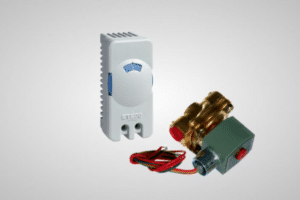

As with the standard Panel Cooler there is the optional Thermostats and Solenoid Valve System and Electronic Thermostats System for on-off control and Bypass system if constant purge is required inside (to keep out a dirty environment).

Dimensions

Selection

All units 303/304 stainless steel for corrosive environments and long life. Utilizing a hot and cold end muffling kit the unit is made extra quiet to under 64 dBA depending on capacity. The hot end muffler also acts a “heat guard” – you can wrap your hand around it without feeling much heat.

All units 303/304 stainless steel for corrosive environments and long life. Utilizing a hot and cold end muffling kit the unit is made extra quiet to under 64 dBA depending on capacity. The hot end muffler also acts a “heat guard” – you can wrap your hand around it without feeling much heat.

Silent Frigid-X® NEMA 12 (IP56) Quiet Panel Coolers

- Silent Frigid-X® NEMA 12 (IP56) Quiet Panel Coolers for standard cabinet enclosures and panels.

Silent Frigid-X® NEMA 3R (IP24) Quiet Panel Coolers

- Silent Frigid-X® NEMA 3R (IP24) Quiet Panel Coolers for cabinet enclosures and panels in outdoor use.

Silent Frigid-X® NEMA 4-4x (IP66) Quiet Panel Coolers

- Silent Frigid-X® NEMA 4-4x (IP66) Quiet Panel Coolers for cabinet enclosures and panels in wash down applications.

Contact Nex Flow® for assistance in sizing cabinet enclosure cooler – Frigid-X series. See Below for Sizing Specifications

| TYPE | MODEL | CAPACITY BTU/hr (Watts)* |

Thermostat Control |

Sound Level dBA at 80 PSIG (5.5 bar) |

|---|---|---|---|---|

| NEMA TYPE 12 (IP 54) | 61004A-X | 290 (85) | Not included | 58 |

| NEMA TYPE 12 (IP 54) | 61008A-X | 580 (170) | Not included | 60 |

| NEMA TYPE 12 (IP 54) | 61015A-X | 1100 (322) | Not included | 67 |

| NEMA TYPE 12 (IP 54) | 61025A-X | 1800 (527) | Not included | 68 |

| NEMA TYPE 12 (IP 54) | 61030A-X | 2100 (615) | Not included | 68 |

| NEMA TYPE 12 (IP 54) | 61040A-X | 2900 (849) | Not included | 69 |

| NEMA TYPE 12 (IP 54) | 63004A-X | 290 (85) | Included | 58 |

| NEMA TYPE 12 (IP 54) | 63008A-X | 580(170) | Included | 60 |

| NEMA TYPE 12 (IP 54) | 63015A-X | 1100 (322) | Included | 67 |

| NEMA TYPE 12 (IP 54) | 63025A-X | 1800 (527) | Included | 68 |

| NEMA TYPE 12 (IP 54) | 63030A-X | 2100 (615) | Included | 68 |

| NEMA TYPE 12 (IP 54) | 63040A-X | 2900 (849) | Included | 69 |

| NEMA TYPE 3R (IP 24) | 61004R-X | 290 (85) | Not included | 58 |

| NEMA TYPE 3R (IP 24) | 61008R-X | 580(170) | Not included | 60 |

| NEMA TYPE 3R (IP 24) | 61015R-X | 1100 (322) | Not included | 67 |

| NEMA TYPE 3R (IP 24) | 61025R-X | 1800 (527) | Not included | 68 |

| NEMA TYPE 3R (IP 24) | 61030R-X | 2100 (615) | Not included | 68 |

| NEMA TYPE 3R (IP 24) | 61040R-X | 2900 (849) | Not included | 67 |

| NEMA TYPE 3R (IP 24) | 63004R-X | 290 (85) | Included | 58 |

| NEMA TYPE 3R (IP 24) | 63008R-X | 580(170) | Included | 60 |

| NEMA TYPE 3R (IP 24) | 63015R-X | 1100 (322) | Included | 67 |

| NEMA TYPE 3R (IP 24) | 63025R-X | 1800 (527) | Included | 68 |

| NEMA TYPE 3R (IP 24) | 63030R-X | 2100 (615) | Included | 68 |

| NEMA TYPE 3R (IP 24) | 63040R-X | 2900 (849) | Included | 69 |

| Patented*NEMA TYPE 4-4X (IP 66) | 61104X-X | 290 (85) | Not included | 58 |

| Patented*NEMA TYPE 4-4X (IP 66) | 61125X-X | 580(170) | Not included | 60 |

| Patented*NEMA TYPE 4-4X (IP 66) | 61130X-X | 1100 (322) | Not included | 67 |

| Patented*NEMA TYPE 4-4X (IP 66) | 61140X-X | 1800 (527) | Not included | 68 |

| Patented*NEMA TYPE 4-4X (IP 66) | 63104X-X | 2100 (615) | Not included | 68 |

| Patented*NEMA TYPE 4-4X (IP 66) | 63108X-X | 2900 (849) | Not included | 69 |

| Patented*NEMA TYPE 4-4X (IP 66) | 63104X-X | 290 (85) | Included | 58 |

| Patented*NEMA TYPE 4-4X (IP 66) | 63108X-X | 580(170) | Included | 60 |

| Patented*NEMA TYPE 4-4X (IP 66) | 63115X-X | 1100 (322) | Included | 67 |

| Patented*NEMA TYPE 4-4X (IP 66) | 63125X-X | 1800 (527) | Included | 68 |

| Patented*NEMA TYPE 4-4X (IP 66) | 63130X-X | 2100 (615) | Included | 68 |

| Patented*NEMA TYPE 4-4X (IP 66) | 63140X-X | 2900 (849) | Included | 69 |

** In 316 environments normally customers will already have special filtration systems. *Cooling effect based on 95°F temperature inside cabinet, 100 PSIG (6.9 BAR) compressor inlet pressure, and 70ºF (21ºC) inlet temperature. BTU/hr. figures rounded to nearest 100 BTU/hr (1 WATT). All Continuous Operation models include the cooling unit, filter with auto drain and cold air distribution kit. All On-Off control units include the cooling unit, filter with auto drain, cold air distribution kit, solenoid valve and thermostat.

Silent Frigid X Panel Cooler

Calculating Heat Load

You can use our online panel cooler calculator,

or, If you would like us to do the calculation for you, or purchase consultation and we will followup with you.

If you have any questions please email: support@nexflow.com

Total heat load consists of the heat transfer from outside your panel and from the heat dissipated inside the control unit.

Useful terms and conversions:

1 BTU/hr = 0.293 watts

1 BTU/hr – 0.000393 horsepower

1 Watt = 3.415 BTU/hr

1 horsepower = 2544 BTU/hr

1 Watt = 0.00134 horsepower

1 Square Foot = 0.0929 square meters

1 Square Meter = 10.76 square foot

Typical fan capacity:

4″ fan: 100 CFM (2832 LPM)

6″ fan: 220 CFM (6230 LPM)

8″ fan: 340 CFM (9628 LPM)

10″ fan 550 CFM (15574 LPM)

BTU/hr. cooling effect from fan 1.08 x (temp. inside panel in °F – temp. outside panel in degrees F) x CFM.

Watts cooling effect from fan: 0.16 x (temp. inside panel in °C – temp. outside panel in degrees C) x LPM.

Calculating BTU/hr. or Watts:

- Determine the heat generated inside the enclosure. Approximations may be necessary. For example, if you know the power generated inside the unit, assume 10% of the energy is dissipated as heat.

- For heat transfer from the outside, calculate the area exposed to the atmosphere except for the top of the control panel.

- Choose the internal temperature you wish to have, and choose the temperature difference between it and the maximum external temperature expected.

- From the conversion table that follows, determine the BTU/hr. per square foot (or watts per square meter) for the temperature difference.

- Multiply the panel surface area times the BTU/hr. per square foot (or watts per square meter) to get the external heat transfer in BTU/hr or in watts.

- Sum the internal and external heat loads calculated.

- If you do not know the power used in the enclosure but you can measure temperatures, then measure the temperature difference between the outside at current temperature, and the present internal cabinet temperature.

- Note size and number of any external fans. Provide this information to Nex Flow® to assist in sizing the appropriate cooling system.

| Temperature Difference in °F | BTU/hr./sq. ft. | Temperature Difference in °C | Watts/sq.m |

|---|---|---|---|

| 5 | 1.5 | 3 | 5.2 |

| 10 | 3.3 | 6 | 11.3 |

| 15 | 5.1 | 9 | 17.6 |

| 20 | 7.1 | 12 | 24.4 |

| 25 | 9.1 | 15 | 31.4 |

| 30 | 11.3 | 18 | 39.5 |

| 35 | 13.8 | 21 | 47.7 |

| 40 | 16.2 | 24 | 55.6 |

Example:

The control panel coolers have two frequency drives totaling 10 horsepower and one module rated at 100 watts. The maximum outside temperature expected is 105°F or 40.5°C. The area of the control panel cooler exposed sides, except for the top is 42 square feet or 3.9 square meters. We want the internal temperature to be 95° or 35°C.

Total internal power is 10 hp x 746 watts/hp – 7460 plus 100 watts = 7560 watts.

Assume 10% forms heat = an internal heat load of 756 watts.

Or

Total internal power is 10 hp x 2544 BTU/hp = 25440 BTU/hr plus 100 watts x 3.415 BTU/hr/watt = 25782 BTU/hr.

Assume 10% forms heat = an internal heat load of 2578 BTU/hr.

External heat load: The temperature difference between the desired temperature and the outside is 10°F or 5.5°C. Using the conversions (and interpolating where necessary) we multiply the area by the conversion factor:

42 sq. ft x 3.3 – 139 BTU/hr or 3.9 sq. m x 10.3 = 40 watts

Total Heat Load: 756 + 40 – 796 watts or 2578 + 139 – 2717 BTU/hr.

You would use a Model 61040 for constant operation or a Model 63040 for one-off control. (Rated at 2900 BTU/hr or 849 watts).

| Silent Frigid-X™ Panel Coolers | ||

|---|---|---|

| PART NO. | DESCRIPTION | PRICE US DOLLARS |

| 61002A-X | NEMA 12 FRIGID-X™ Enclosure Cooler Only + hose kit + filter (90004) - continuous system + 69506 Kit | $674.00 |

| 61004A-X | NEMA 12 FRIGID-X™ Enclosure Cooler Only + hose kit + filter (90004) - continuous system + 69506 Kit | $674.00 |

| 61008A-X | NEMA 12 FRIGID-X™ Enclosure Cooler Only + hose kit + filter (90004) - continuous system + 69506 Kit | $674.00 |

| 61010A-X | NEMA 12 FRIGID-X™ Enclosure Cooler Only + hose kit + filter (90004) - continuous system + 69505 Kit | $797.00 |

| 61015A-X | NEMA 12 FRIGID-X™ Enclosure Cooler Only + hose kit + filter (90004) - continuous system + 69505 Kit | $797.00 |

| 61025A-X | NEMA 12 FRIGID-X™ Enclosure Cooler Only + hose kit + filter (90004) - continuous system + 69505 Kit | $797.00 |

| 61030A-X | NEMA 12 FRIGID-X™ Enclosure Cooler Only + hose kit + filter (90004) - continuous system + 69505 Kit | $797.00 |

| 61040A-X | NEMA 12 FRIGID-X™ Enclosure Cooler Only + hose kit + filter (90004) - continuous system + 69505 Kit | $797.00 |

| 61002R-X | NEMA 3R FRIGID-X™ Enclosure Cooler Only + hose kit + filter (90004) - continuous system + 69506 Kit | $689.00 |

| 61004R-X | NEMA 3R FRIGID-X™ Enclosure Cooler Only + hose kit + filter (90004) - continuous system + 69506 Kit | $689.00 |

| 61008R-X | NEMA 3R FRIGID-X™ Enclosure Cooler Only + hose kit + filter (90004) - continuous system + 69506 Kit | $689.00 |

| 61010R-X | NEMA 3R FRIGID-X™ Enclosure Cooler Only + hose kit + filter (90004) - continuous system + 69505 Kit | $812.00 |

| 61015R-X | NEMA 3R FRIGID-X™ Enclosure Cooler Only + hose kit + filter (90004) - continuous system + 69505 Kit | $812.00 |

| 61025R-X | NEMA 3R FRIGID-X™ Enclosure Cooler Only + hose kit + filter (90004) - continuous system + 69505 Kit | $812.00 |

| 61030R-X | NEMA 3R FRIGID-X™ Enclosure Cooler Only + hose kit + filter (90004) - continuous system + 69505 Kit | $812.00 |

| 61040R-X | NEMA 3R FRIGID-X™ Enclosure Cooler Only + hose kit + filter (90004) - continuous system + 69505 Kit | $812.00 |

| 61102X-X | NEMA 4-4X FRIGID-X™ Enclosure Cooler Only + hose kit + filter (90007) - continuous system + 69506 Kit | $821.00 |

| 61104X-X | NEMA 4-4X FRIGID-X™ Enclosure Cooler Only + hose kit + filter (90007) - continuous system + 69506 Kit | $821.00 |

| 61108X-X | NEMA 4-4X FRIGID-X™ Enclosure Cooler Only + hose kit + filter (90007) - continuous system + 69506 Kit | $821.00 |

| 61110X-X | NEMA 4-4X FRIGID-X™ Enclosure Cooler Only + hose kit + filter (90007) - continuous system + 69505 Kit | $863.00 |

| 61115X-X | NEMA 4-4X FRIGID-X™ Enclosure Cooler Only + hose kit + filter (90007) - continuous system + 69505 Kit | $863.00 |

| 61125X-X | NEMA 4-4X FRIGID-X™ Enclosure Cooler Only + hose kit + filter (90007) - continuous system + 69505 Kit | $863.00 |

| 61130X-X | NEMA 4-4X FRIGID-X™ Enclosure Cooler Only + hose kit + filter (90007) - continuous system + 69505 Kit | $863.00 |

| 61140X-X | NEMA 4-4X FRIGID-X™ Enclosure Cooler Only + hose kit + filter (90007) - continuous system + 69505 Kit | $863.00 |

| 63002A-X | NEMA 12 FRIGID-X™ Cl. + hose kit + filter + therm. (90017) & sol.(90020) - on/off control std therm. + 69506 Kit | $1,050.00 |

| 63004A-X | NEMA 12 FRIGID-X™ Cl. + hose kit + filter + therm. (90017) & sol.(90020) - on/off control std therm. + 69506 Kit | $1,050.00 |

| 63008A-X | NEMA 12 FRIGID-X™ Cl. + hose kit + filter + therm. (90017) & sol.(90020) - on/off control std therm. + 69506 Kit | $1,050.00 |

| 63010A-X | NEMA 12 FRIGID-X™ Cl. + hose kit + filter + therm. (90017) & sol.(90020) - on/off control std therm + 69505 Kit | $1,173.00 |

| 63015A-X | NEMA 12 FRIGID-X™ Cl. + hose kit + filter + therm. (90017) & sol.(90020) - on/off control std therm + 69505 Kit | $1,173.00 |

| 63025A-X | NEMA 12 FRIGID-X™ Cl. + hose kit + filter + therm. (90017) & sol.(90020) - on/off control std therm + 69505 Kit | $1,173.00 |

| 63030A-X | NEMA 12 FRIGID-X™ Cl. + hose kit + filter + therm. (90017) & sol.(90020) - on/off control std therm + 69505 Kit | $1,173.00 |

| 63040A-X | NEMA 12 FRIGID-X™ Cl. + hose kit + filter + therm. (90017) & sol.(90020) - on/off control std therm + 69505 Kit | $1,173.00 |

| 63002R-X | NEMA 3R FRIGID-X™ Cl. + hose kit + filter + therm. (90017) & sol.(90020) - on/off control std therm + 69506 Kit | $1,065.00 |

| 63004R-X | NEMA 3R FRIGID-X™ Cl. + hose kit + filter + therm. (90017) & sol.(90020) - on/off control std therm + 69506 Kit | $1,065.00 |

| 63008R-X | NEMA 3R FRIGID-X™ Cl. + hose kit + filter + therm. (90017) & sol.(90020) - on/off control std therm + 69506 Kit | $1,065.00 |

| 63010R-X | NEMA 3R FRIGID-X™ Cl. + hose kit + filter + therm. (90017) & sol.(90020) - on/off control std therm + 69505 Kit | $1,188.00 |

| 63015R-X | NEMA 3R FRIGID-X™ Cl. + hose kit + filter + therm. (90017) & sol.(90020) - on/off control std therm + 69505 Kit | $1,188.00 |

| 63025R-X | NEMA 3R FRIGID-X™ Cl. + hose kit + filter + therm. (90017) & sol.(90020) - on/off control std therm + 69505 Kit | $1,188.00 |

| 63030R-X | NEMA 3R FRIGID-X™ Cl. + hose kit + filter + therm. (90017) & sol.(90020) - on/off control std therm + 69505 Kit | $1,188.00 |

| 63040R-X | NEMA 3R FRIGID-X™ Cl. + hose kit + filter + therm. (90017) & sol.(90020) - on/off control std therm + 69505 Kit | $1,188.00 |

| 63102X-X | NEMA 4-4X FRIGID-X™ Encl. Cl. + hs kit + fr + ther. (90017) & sol.(90018) - on/off control std therm + 69506 Kit | $1,197.00 |

| 63104X-X | NEMA 4-4X FRIGID-X™ Encl. Cl. + hs kit + fr + ther. (90017) & sol.(90018) - on/off control std therm + 69506 Kit | $1,197.00 |

| 63108X-X | NEMA 4-4X FRIGID-X™ Encl. Cl. + hs kit + fr + ther. (90017) & sol.(90018) - on/off control std therm + 69506 Kit | $1,197.00 |

| 63110X-X | NEMA 4-4X FRIGID-X™ Encl. Cl. + hs kit + fr + ther. (90017) & sol.(90018) - on/off control std therm + 69505 Kit | $1,239.00 |

| 63115X-X | NEMA 4-4X FRIGID-X™ Encl. Cl. + hs kit + fr + ther. (90017) & sol.(90018) - on/off control std therm + 69505 Kit | $1,239.00 |

| 63125X-X | NEMA 4-4X FRIGID-X™ Encl. Cl. + hs kit + fr + ther. (90017) & sol.(90018) - on/off control std therm + 69505 Kit | $1,239.00 |

| 63130X-X | NEMA 4-4X FRIGID-X™ Encl. Cl. + hs kit + fr + ther. (90017) & sol.(90018) - on/off control std therm + 69505 Kit | $1,239.00 |

| 63140X-X | NEMA 4-4X FRIGID-X™ Encl. Cl. + hs kit + fr + ther. (90017) & sol.(90018) - on/off control std therm + 69505 Kit | $1,239.00 |

| More Information or Buy Here |

| Frigid-X™ By-Pass System for Panel cooler | ||

|---|---|---|

| PART NO. | DESCRIPTION | PRICE US DOLLARS |

| 69700 | Bypass System to make a constant purge system – One system for each cooler is necessary | $250.00 |

| More Information or Buy Here |

- Overview

-

Product Overview

The Silent Frigid-X® Panel Cooler series for electronic control panels provide a low cost method of both purging and cooling electrical and electronic control panels by using a stainless steel vortex tube to create cold air from ordinary compressed air. By Utilizing a hot and cold end muffling kit the unit is made extra quiet to under 64 dBA depending on capacity. The hot end muffler also acts as a “heat guard” – you can wrap your hand around it without feeling much heat. The hot air is exhausted safely underneath the hot end muffler.

The panel cooler series are compact and can be installed in minutes through a standard electrical knockout. There are virtually no moving parts.

* US patent number 8,616,010 / Other countries: Patented or Patent Pending *

Note: Always question non-approved units used on electrical enclosures to ensure that your panels are not damaged by inferior products.

You can use our online panel cooler calculator,

or, If you would like us to do the calculation for you, or purchase consultation and we will followup with you.

If you have any questions please email: support@nexflow.com

- Advantages

-

Features / Advantages

- Low cost

- Compact

- No CFCs

- Fast installation

- Stabilize enclosure temperature and humidity

- Virtually maintenance free (No Moving Parts)

- Mounts in a standard electrical knockout

- Stops heat damage and nuisance tripping

- Eliminates fans and filters

- Prevents dirt contamination by keeping enclosure at positive pressure

- Units applicable to all environments including high temperature to 200ºF

- Videos

-

Videos

How The Silent Frigid X Cabinet Enclosure Cooler Works

The regular Frigid-X® Panel Coolers are under 78 dBA for noise level but in some instances it is not enough and a quieter version is necessary. This is where the Silent X-Stream® Panel Cooler can be utilized. It can reduce noise levels to 65 dBA It works the same way as a regular Panel Cooler where compressed air enters at point (A) into the vortex tube component of the panel cooler. The vortex tube creates two streams of compressed air – a hot stream at (B) and a cold stream at (C). The hot air stream from the vortex tube is vented outside the system at (D) after internal muffling. An additional Hot End muffler (I) reduces the noise further and also acts a protection cover over the hot end should anyone try to grab the unit. Hot air from inside the control panel is vented at point (E) to the outside. Cold air goes into the control panel at (F) into an additional cold end muffler (J) and then into the cold distribution hose (G). Holes (H) are punched into the hose kit to distribute the cold air inside the panel. A muffler (I) further reduces the noise level of the exhausting at the end of the hose.

Silent Frigid X Panel Cooler

As with the standard Panel Cooler there is the optional Thermostats and Solenoid Valve System and Electronic Thermostats System for on-off control and Bypass system if constant purge is required inside (to keep out a dirty environment).

- Dimensions

-

Dimensions

- Selection

-

Selection

All units 303/304 stainless steel for corrosive environments and long life. Utilizing a hot and cold end muffling kit the unit is made extra quiet to under 64 dBA depending on capacity. The hot end muffler also acts a “heat guard” – you can wrap your hand around it without feeling much heat.

All units 303/304 stainless steel for corrosive environments and long life. Utilizing a hot and cold end muffling kit the unit is made extra quiet to under 64 dBA depending on capacity. The hot end muffler also acts a “heat guard” – you can wrap your hand around it without feeling much heat.Silent Frigid-X® NEMA 12 (IP56) Quiet Panel Coolers

- Silent Frigid-X® NEMA 12 (IP56) Quiet Panel Coolers for standard cabinet enclosures and panels.

Silent Frigid-X® NEMA 3R (IP24) Quiet Panel Coolers

- Silent Frigid-X® NEMA 3R (IP24) Quiet Panel Coolers for cabinet enclosures and panels in outdoor use.

Silent Frigid-X® NEMA 4-4x (IP66) Quiet Panel Coolers

- Silent Frigid-X® NEMA 4-4x (IP66) Quiet Panel Coolers for cabinet enclosures and panels in wash down applications.

Contact Nex Flow® for assistance in sizing cabinet enclosure cooler – Frigid-X series. See Below for Sizing Specifications

TYPE MODEL CAPACITY

BTU/hr

(Watts)*Thermostat

ControlSound

Level

dBA at 80 PSIG (5.5 bar)NEMA TYPE 12 (IP 54) 61004A-X 290 (85) Not included 58 NEMA TYPE 12 (IP 54) 61008A-X 580 (170) Not included 60 NEMA TYPE 12 (IP 54) 61015A-X 1100 (322) Not included 67 NEMA TYPE 12 (IP 54) 61025A-X 1800 (527) Not included 68 NEMA TYPE 12 (IP 54) 61030A-X 2100 (615) Not included 68 NEMA TYPE 12 (IP 54) 61040A-X 2900 (849) Not included 69 NEMA TYPE 12 (IP 54) 63004A-X 290 (85) Included 58 NEMA TYPE 12 (IP 54) 63008A-X 580(170) Included 60 NEMA TYPE 12 (IP 54) 63015A-X 1100 (322) Included 67 NEMA TYPE 12 (IP 54) 63025A-X 1800 (527) Included 68 NEMA TYPE 12 (IP 54) 63030A-X 2100 (615) Included 68 NEMA TYPE 12 (IP 54) 63040A-X 2900 (849) Included 69 NEMA TYPE 3R (IP 24) 61004R-X 290 (85) Not included 58 NEMA TYPE 3R (IP 24) 61008R-X 580(170) Not included 60 NEMA TYPE 3R (IP 24) 61015R-X 1100 (322) Not included 67 NEMA TYPE 3R (IP 24) 61025R-X 1800 (527) Not included 68 NEMA TYPE 3R (IP 24) 61030R-X 2100 (615) Not included 68 NEMA TYPE 3R (IP 24) 61040R-X 2900 (849) Not included 67 NEMA TYPE 3R (IP 24) 63004R-X 290 (85) Included 58 NEMA TYPE 3R (IP 24) 63008R-X 580(170) Included 60 NEMA TYPE 3R (IP 24) 63015R-X 1100 (322) Included 67 NEMA TYPE 3R (IP 24) 63025R-X 1800 (527) Included 68 NEMA TYPE 3R (IP 24) 63030R-X 2100 (615) Included 68 NEMA TYPE 3R (IP 24) 63040R-X 2900 (849) Included 69 Patented*NEMA TYPE 4-4X (IP 66) 61104X-X 290 (85) Not included 58 Patented*NEMA TYPE 4-4X (IP 66) 61125X-X 580(170) Not included 60 Patented*NEMA TYPE 4-4X (IP 66) 61130X-X 1100 (322) Not included 67 Patented*NEMA TYPE 4-4X (IP 66) 61140X-X 1800 (527) Not included 68 Patented*NEMA TYPE 4-4X (IP 66) 63104X-X 2100 (615) Not included 68 Patented*NEMA TYPE 4-4X (IP 66) 63108X-X 2900 (849) Not included 69 Patented*NEMA TYPE 4-4X (IP 66) 63104X-X 290 (85) Included 58 Patented*NEMA TYPE 4-4X (IP 66) 63108X-X 580(170) Included 60 Patented*NEMA TYPE 4-4X (IP 66) 63115X-X 1100 (322) Included 67 Patented*NEMA TYPE 4-4X (IP 66) 63125X-X 1800 (527) Included 68 Patented*NEMA TYPE 4-4X (IP 66) 63130X-X 2100 (615) Included 68 Patented*NEMA TYPE 4-4X (IP 66) 63140X-X 2900 (849) Included 69 ** In 316 environments normally customers will already have special filtration systems. *Cooling effect based on 95°F temperature inside cabinet, 100 PSIG (6.9 BAR) compressor inlet pressure, and 70ºF (21ºC) inlet temperature. BTU/hr. figures rounded to nearest 100 BTU/hr (1 WATT). All Continuous Operation models include the cooling unit, filter with auto drain and cold air distribution kit. All On-Off control units include the cooling unit, filter with auto drain, cold air distribution kit, solenoid valve and thermostat.

Silent Frigid X Panel Cooler

- Calculating Heat Load

-

Calculating Heat Load

You can use our online panel cooler calculator,

or, If you would like us to do the calculation for you, or purchase consultation and we will followup with you.

If you have any questions please email: support@nexflow.com

Total heat load consists of the heat transfer from outside your panel and from the heat dissipated inside the control unit.

Useful terms and conversions:

1 BTU/hr = 0.293 watts

1 BTU/hr – 0.000393 horsepower

1 Watt = 3.415 BTU/hr

1 horsepower = 2544 BTU/hr

1 Watt = 0.00134 horsepower

1 Square Foot = 0.0929 square meters

1 Square Meter = 10.76 square footTypical fan capacity:

4″ fan: 100 CFM (2832 LPM)

6″ fan: 220 CFM (6230 LPM)

8″ fan: 340 CFM (9628 LPM)

10″ fan 550 CFM (15574 LPM)BTU/hr. cooling effect from fan 1.08 x (temp. inside panel in °F – temp. outside panel in degrees F) x CFM.

Watts cooling effect from fan: 0.16 x (temp. inside panel in °C – temp. outside panel in degrees C) x LPM.

Calculating BTU/hr. or Watts:

- Determine the heat generated inside the enclosure. Approximations may be necessary. For example, if you know the power generated inside the unit, assume 10% of the energy is dissipated as heat.

- For heat transfer from the outside, calculate the area exposed to the atmosphere except for the top of the control panel.

- Choose the internal temperature you wish to have, and choose the temperature difference between it and the maximum external temperature expected.

- From the conversion table that follows, determine the BTU/hr. per square foot (or watts per square meter) for the temperature difference.

- Multiply the panel surface area times the BTU/hr. per square foot (or watts per square meter) to get the external heat transfer in BTU/hr or in watts.

- Sum the internal and external heat loads calculated.

- If you do not know the power used in the enclosure but you can measure temperatures, then measure the temperature difference between the outside at current temperature, and the present internal cabinet temperature.

- Note size and number of any external fans. Provide this information to Nex Flow® to assist in sizing the appropriate cooling system.

Temperature Difference in °F BTU/hr./sq. ft. Temperature Difference in °C Watts/sq.m 5 1.5 3 5.2 10 3.3 6 11.3 15 5.1 9 17.6 20 7.1 12 24.4 25 9.1 15 31.4 30 11.3 18 39.5 35 13.8 21 47.7 40 16.2 24 55.6 Example:

The control panel coolers have two frequency drives totaling 10 horsepower and one module rated at 100 watts. The maximum outside temperature expected is 105°F or 40.5°C. The area of the control panel cooler exposed sides, except for the top is 42 square feet or 3.9 square meters. We want the internal temperature to be 95° or 35°C.

Total internal power is 10 hp x 746 watts/hp – 7460 plus 100 watts = 7560 watts.

Assume 10% forms heat = an internal heat load of 756 watts.Or

Total internal power is 10 hp x 2544 BTU/hp = 25440 BTU/hr plus 100 watts x 3.415 BTU/hr/watt = 25782 BTU/hr.

Assume 10% forms heat = an internal heat load of 2578 BTU/hr.

External heat load: The temperature difference between the desired temperature and the outside is 10°F or 5.5°C. Using the conversions (and interpolating where necessary) we multiply the area by the conversion factor:

42 sq. ft x 3.3 – 139 BTU/hr or 3.9 sq. m x 10.3 = 40 watts

Total Heat Load: 756 + 40 – 796 watts or 2578 + 139 – 2717 BTU/hr.

You would use a Model 61040 for constant operation or a Model 63040 for one-off control. (Rated at 2900 BTU/hr or 849 watts).

- Pricing

-

Silent Frigid-X™ Panel Coolers PART NO. DESCRIPTION PRICE US DOLLARS 61002A-X NEMA 12 FRIGID-X™ Enclosure Cooler Only + hose kit + filter (90004) - continuous system + 69506 Kit $674.00 61004A-X NEMA 12 FRIGID-X™ Enclosure Cooler Only + hose kit + filter (90004) - continuous system + 69506 Kit $674.00 61008A-X NEMA 12 FRIGID-X™ Enclosure Cooler Only + hose kit + filter (90004) - continuous system + 69506 Kit $674.00 61010A-X NEMA 12 FRIGID-X™ Enclosure Cooler Only + hose kit + filter (90004) - continuous system + 69505 Kit $797.00 61015A-X NEMA 12 FRIGID-X™ Enclosure Cooler Only + hose kit + filter (90004) - continuous system + 69505 Kit $797.00 61025A-X NEMA 12 FRIGID-X™ Enclosure Cooler Only + hose kit + filter (90004) - continuous system + 69505 Kit $797.00 61030A-X NEMA 12 FRIGID-X™ Enclosure Cooler Only + hose kit + filter (90004) - continuous system + 69505 Kit $797.00 61040A-X NEMA 12 FRIGID-X™ Enclosure Cooler Only + hose kit + filter (90004) - continuous system + 69505 Kit $797.00 61002R-X NEMA 3R FRIGID-X™ Enclosure Cooler Only + hose kit + filter (90004) - continuous system + 69506 Kit $689.00 61004R-X NEMA 3R FRIGID-X™ Enclosure Cooler Only + hose kit + filter (90004) - continuous system + 69506 Kit $689.00 61008R-X NEMA 3R FRIGID-X™ Enclosure Cooler Only + hose kit + filter (90004) - continuous system + 69506 Kit $689.00 61010R-X NEMA 3R FRIGID-X™ Enclosure Cooler Only + hose kit + filter (90004) - continuous system + 69505 Kit $812.00 61015R-X NEMA 3R FRIGID-X™ Enclosure Cooler Only + hose kit + filter (90004) - continuous system + 69505 Kit $812.00 61025R-X NEMA 3R FRIGID-X™ Enclosure Cooler Only + hose kit + filter (90004) - continuous system + 69505 Kit $812.00 61030R-X NEMA 3R FRIGID-X™ Enclosure Cooler Only + hose kit + filter (90004) - continuous system + 69505 Kit $812.00 61040R-X NEMA 3R FRIGID-X™ Enclosure Cooler Only + hose kit + filter (90004) - continuous system + 69505 Kit $812.00 61102X-X NEMA 4-4X FRIGID-X™ Enclosure Cooler Only + hose kit + filter (90007) - continuous system + 69506 Kit $821.00 61104X-X NEMA 4-4X FRIGID-X™ Enclosure Cooler Only + hose kit + filter (90007) - continuous system + 69506 Kit $821.00 61108X-X NEMA 4-4X FRIGID-X™ Enclosure Cooler Only + hose kit + filter (90007) - continuous system + 69506 Kit $821.00 61110X-X NEMA 4-4X FRIGID-X™ Enclosure Cooler Only + hose kit + filter (90007) - continuous system + 69505 Kit $863.00 61115X-X NEMA 4-4X FRIGID-X™ Enclosure Cooler Only + hose kit + filter (90007) - continuous system + 69505 Kit $863.00 61125X-X NEMA 4-4X FRIGID-X™ Enclosure Cooler Only + hose kit + filter (90007) - continuous system + 69505 Kit $863.00 61130X-X NEMA 4-4X FRIGID-X™ Enclosure Cooler Only + hose kit + filter (90007) - continuous system + 69505 Kit $863.00 61140X-X NEMA 4-4X FRIGID-X™ Enclosure Cooler Only + hose kit + filter (90007) - continuous system + 69505 Kit $863.00 63002A-X NEMA 12 FRIGID-X™ Cl. + hose kit + filter + therm. (90017) & sol.(90020) - on/off control std therm. + 69506 Kit $1,050.00 63004A-X NEMA 12 FRIGID-X™ Cl. + hose kit + filter + therm. (90017) & sol.(90020) - on/off control std therm. + 69506 Kit $1,050.00 63008A-X NEMA 12 FRIGID-X™ Cl. + hose kit + filter + therm. (90017) & sol.(90020) - on/off control std therm. + 69506 Kit $1,050.00 63010A-X NEMA 12 FRIGID-X™ Cl. + hose kit + filter + therm. (90017) & sol.(90020) - on/off control std therm + 69505 Kit $1,173.00 63015A-X NEMA 12 FRIGID-X™ Cl. + hose kit + filter + therm. (90017) & sol.(90020) - on/off control std therm + 69505 Kit $1,173.00 63025A-X NEMA 12 FRIGID-X™ Cl. + hose kit + filter + therm. (90017) & sol.(90020) - on/off control std therm + 69505 Kit $1,173.00 63030A-X NEMA 12 FRIGID-X™ Cl. + hose kit + filter + therm. (90017) & sol.(90020) - on/off control std therm + 69505 Kit $1,173.00 63040A-X NEMA 12 FRIGID-X™ Cl. + hose kit + filter + therm. (90017) & sol.(90020) - on/off control std therm + 69505 Kit $1,173.00 63002R-X NEMA 3R FRIGID-X™ Cl. + hose kit + filter + therm. (90017) & sol.(90020) - on/off control std therm + 69506 Kit $1,065.00 63004R-X NEMA 3R FRIGID-X™ Cl. + hose kit + filter + therm. (90017) & sol.(90020) - on/off control std therm + 69506 Kit $1,065.00 63008R-X NEMA 3R FRIGID-X™ Cl. + hose kit + filter + therm. (90017) & sol.(90020) - on/off control std therm + 69506 Kit $1,065.00 63010R-X NEMA 3R FRIGID-X™ Cl. + hose kit + filter + therm. (90017) & sol.(90020) - on/off control std therm + 69505 Kit $1,188.00 63015R-X NEMA 3R FRIGID-X™ Cl. + hose kit + filter + therm. (90017) & sol.(90020) - on/off control std therm + 69505 Kit $1,188.00 63025R-X NEMA 3R FRIGID-X™ Cl. + hose kit + filter + therm. (90017) & sol.(90020) - on/off control std therm + 69505 Kit $1,188.00 63030R-X NEMA 3R FRIGID-X™ Cl. + hose kit + filter + therm. (90017) & sol.(90020) - on/off control std therm + 69505 Kit $1,188.00 63040R-X NEMA 3R FRIGID-X™ Cl. + hose kit + filter + therm. (90017) & sol.(90020) - on/off control std therm + 69505 Kit $1,188.00 63102X-X NEMA 4-4X FRIGID-X™ Encl. Cl. + hs kit + fr + ther. (90017) & sol.(90018) - on/off control std therm + 69506 Kit $1,197.00 63104X-X NEMA 4-4X FRIGID-X™ Encl. Cl. + hs kit + fr + ther. (90017) & sol.(90018) - on/off control std therm + 69506 Kit $1,197.00 63108X-X NEMA 4-4X FRIGID-X™ Encl. Cl. + hs kit + fr + ther. (90017) & sol.(90018) - on/off control std therm + 69506 Kit $1,197.00 63110X-X NEMA 4-4X FRIGID-X™ Encl. Cl. + hs kit + fr + ther. (90017) & sol.(90018) - on/off control std therm + 69505 Kit $1,239.00 63115X-X NEMA 4-4X FRIGID-X™ Encl. Cl. + hs kit + fr + ther. (90017) & sol.(90018) - on/off control std therm + 69505 Kit $1,239.00 63125X-X NEMA 4-4X FRIGID-X™ Encl. Cl. + hs kit + fr + ther. (90017) & sol.(90018) - on/off control std therm + 69505 Kit $1,239.00 63130X-X NEMA 4-4X FRIGID-X™ Encl. Cl. + hs kit + fr + ther. (90017) & sol.(90018) - on/off control std therm + 69505 Kit $1,239.00 63140X-X NEMA 4-4X FRIGID-X™ Encl. Cl. + hs kit + fr + ther. (90017) & sol.(90018) - on/off control std therm + 69505 Kit $1,239.00 More Information or Buy Here Frigid-X™ By-Pass System for Panel cooler PART NO. DESCRIPTION PRICE US DOLLARS 69700 Bypass System to make a constant purge system – One system for each cooler is necessary $250.00 More Information or Buy Here