Product Overview

The Nex Flow® Ion Blaster Beam® neutralizes static electricity and can remove static charge on a statically charged part and blow off dust up to 15 feet (4.6 m) away with no moving parts. Its compact design allows it to be used in hard to reach areas or confined spaces. The air volume and velocity are infinitely adjustable over a wide range using a pressure regulator to address any application from light to heavy duty.

The Ion Blaster Beam® makes use of an “air amplifier” (Model FX40) mounted on a sturdy metal stand to be able to mount the unit and aim it in the desired direction. On the head of the air amplifier is a plastic attachment with an Ion Point. The amplified airflow passes by the Ion Point, ionizing the air. The plastic attachment is used as metal will tend to draw away some of the ionization weakening the overall effect of static elimination. This maximized, ionized airflow with large entrained volume uses only a minimal amount of compressed air while providing a long, laminar cone of ionized air that will eliminate static charge on the target part.

In most applications only 10 psig (0.7 bar) is required to operate effectively. The Ionizing Point is a powerful ionizer which remains effective because the air exit “plastic PET head” of the unit prevents weakening if ions which metal attachments may do. This makes the Ion Blaster Beam® far more effective than systems using metal.

The Ion Blaster Beam® has a wide range of applications where a static bar with an air knife or other air support cannot be used. An example is blowing ionized air into a cavity such as a plastic container to neutralize it faster and easier, and to loosen dirt and dust stocking due to a static charge.

It is important that the compressed air supply be clean and to have a filter upstream and an automatic drain to remove unwanted moisture. If there is a possibility of oil in the air lines, an oil removal filter with an automatic drain is also recommended. And of course, a regulator to set the line pressure to the lowest level required will minimize compressed air cost.

The unit is rugged, compact, easily mountable, quiet, and uses very little compressed air. It is shockless and safe to use.

Applications

- Eliminate static charge and cleaning parts

- neutralize shrink wrap

- Form fill and seal applications for bag opening

- Neutralizing and cleaning the inside of blow molded parts

- Eliminate static and cleaning of plastic assemblies

- Dust removal from parts prior to painting

- Remove static charge in slitting applications

- Cleaning of packaging

- Neutralization of static charge inside containers.

Features / Advantages

- Effective Static Elimination

- Can clean static free dust at a distance

- Compact design to fit in small spaces

- Stand is pre-drilled for easy mounting

- Low compressed air use

- Rapid static decay

- Quiet Operation

- Shockless and non-radioactive

- Compact and rugged design

- Intake may be ducted to bring in atmospheric air from another area

- No moving parts and minimal maintenance

- Variable flow and force

How The Ion Blaster Beam® Works

Compressed air is supplied at (A) where it enters the air amplifier section of the Ion Blaster Beam and follows the Coanda profile inside the amplifier. Ambient air is entrained at (B) into the amplifier. The Ionizing Point (C) ionizes the amplified airflow exiting as a powerful high flow of static removing, ionized air (D). The unit is mounted on a stand (E) for convenient installation.

Specifications

Certification: North American Power Supplies certified to UL and CSA standards and Spot Ionizer used with the Ion Blaster beam is included with the certification. European Power Supplies CE approved and Spot Ionizer used with the Ion Blaster Beam is included with the certification. Stainless steel emitters on the ionizer.

Electrical: For use with 7 kV rms, 5 milliamperes (max) power supply which will last much longer than 5 kv power supplies.

Electrical Hazard: Shockless (less or equal to 5mA)

Maximum Ambient Temperature: 122 degrees F or 50 degrees C.

| Part NO. | Description |

|---|---|

| 17040 | Ion Blaster Beam® includes Air Amplifier, Spot Ionizers, Stand and 2 meters shielded cable |

| 17140 | Ion Blaster Beam® and Power Supply |

| 17340 | Ion Blaster Beam® Kit (c/w Ion Blaster Beam®, Power supply, Model 90001 water removal filter and Model 90008 regulator with gauge) |

| 80111 | 120 V Power Supply, 2 outlet |

| 80121 | 230 V Power Supply, 2 outlet |

| 80112 | 120 V Power Supply, 4 outlet |

| 80122 | 230 V Power Supply, 4 outlet |

| 90001 | Water Removal Filter c/w auto Drain |

| 90008 | Regulator with gauge |

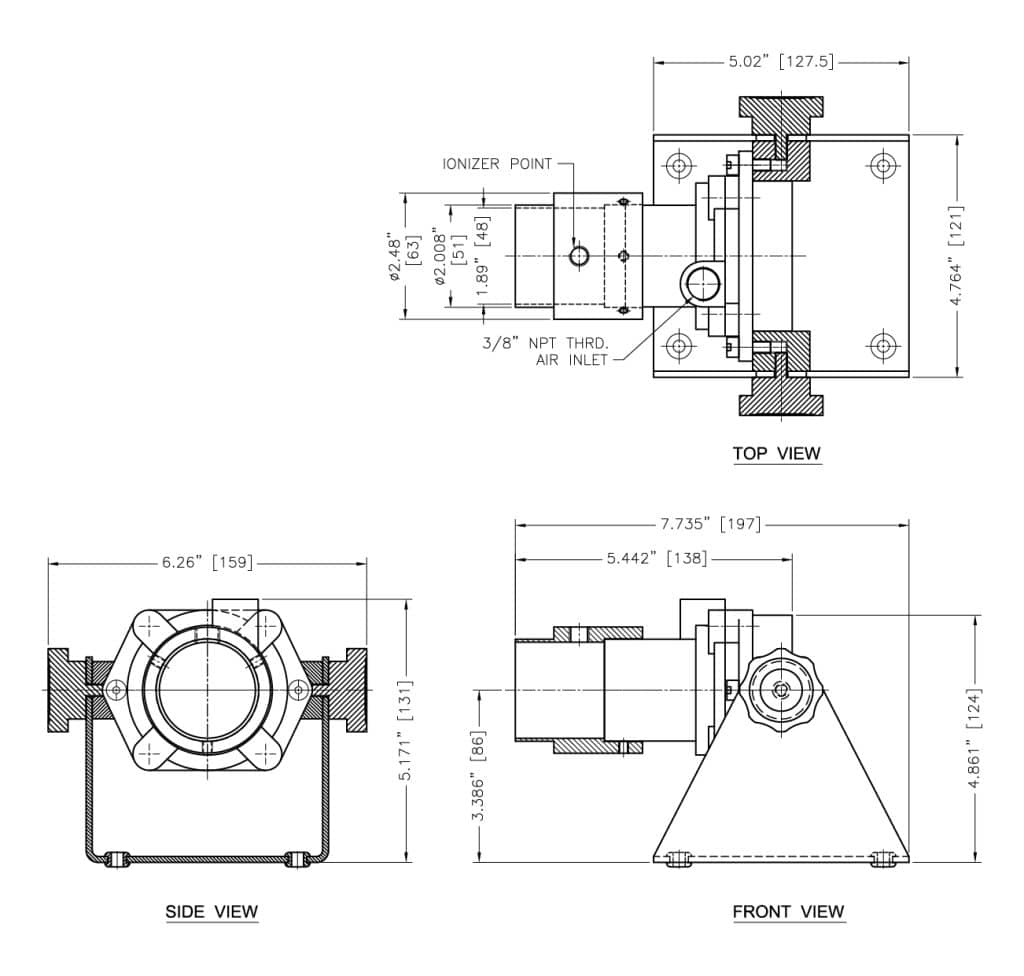

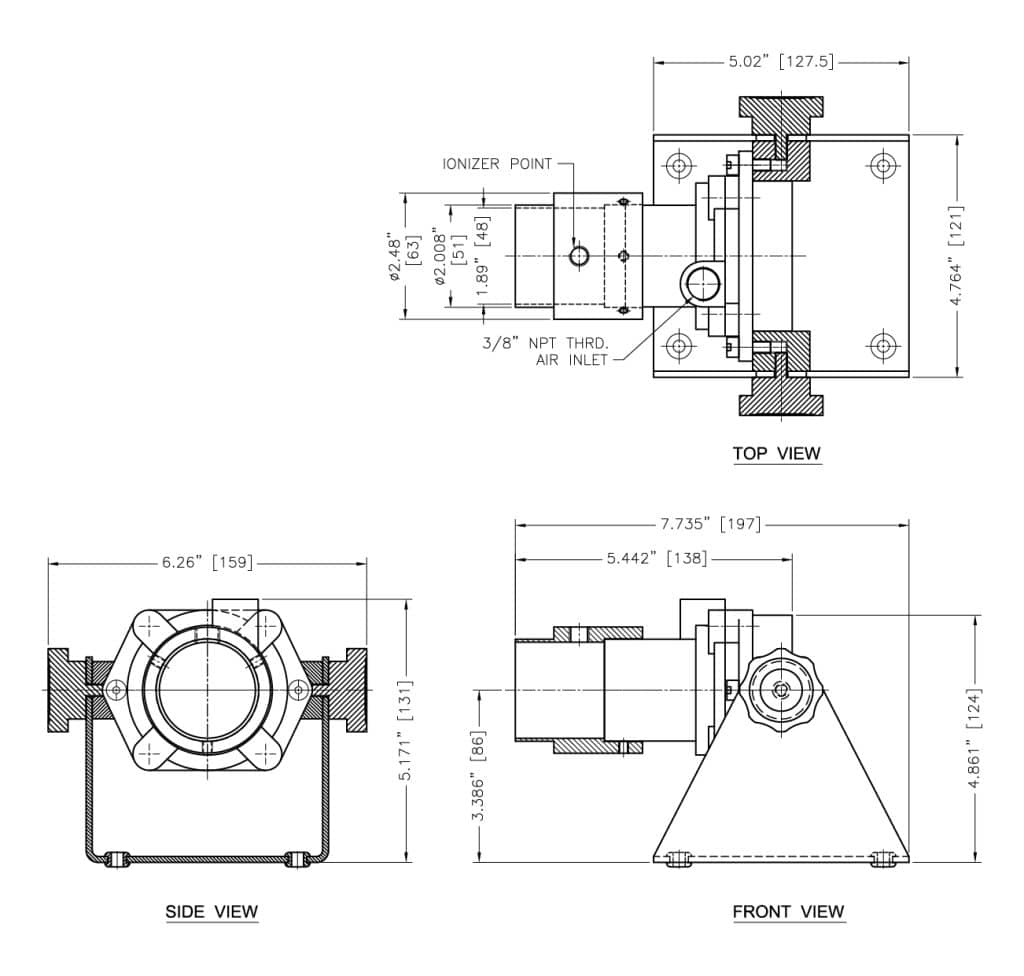

Dimensions

Ion Blaster Beam

Power Supplies

Ion Blaster Beam® power supplies are available in various models including a unit that will monitor the static bars for effectiveness.

| Voltage | Model | Description |

|---|---|---|

| 110V | ENC-110/2 | Two outlet (Can connect two static bars) |

| 220V | ENC-220/2 | Two outlet (Can connect two static bars) |

| 110V | ENC-110/4 | Four outlet (Can connect four static bars) |

| 220V | ENC-220/4 | Four outlet (Can connect four static bars) |

| 110V | Multistat 110 | Four outlet (Can connect four static bars, plus monitors performance. Can be connected into a system alarm or indicating light.) |

| 220V | Multistat 220 | Four outlet (Can connect four) |

NOTE: ENC-2 Power Supply has North American electrical approval

S-Line Power Supply has CE electrical approval

| Ion Blaster Beam™ | |||

|---|---|---|---|

| PART NO. | DESCRIPTION | SIZE | PRICE US DOLLARS |

| 17040 | ION BLASTER BEAM | - | $794.72 |

| 17140 | ION BLASTER BEAM WITH POWER SUPPLY | - | $1,252.72 |

| 17140-CE | ION BLASTER BEAM WITH S-LNE POWER SUPPLY | - | $1,500.72 |

| 17340 | ION BLASTER BEAM KIT (incl 17140 plus 90001 and 90008) | - | $1,452.72 |

| 17340-CE | ION BLASTER BEAM KIT (incl 17140 plus 90004 and 90008) | - | $1,700.72 |

| More Information or Buy Here |

- Overview

-

Product Overview

The Nex Flow® Ion Blaster Beam® neutralizes static electricity and can remove static charge on a statically charged part and blow off dust up to 15 feet (4.6 m) away with no moving parts. Its compact design allows it to be used in hard to reach areas or confined spaces. The air volume and velocity are infinitely adjustable over a wide range using a pressure regulator to address any application from light to heavy duty.

The Ion Blaster Beam® makes use of an “air amplifier” (Model FX40) mounted on a sturdy metal stand to be able to mount the unit and aim it in the desired direction. On the head of the air amplifier is a plastic attachment with an Ion Point. The amplified airflow passes by the Ion Point, ionizing the air. The plastic attachment is used as metal will tend to draw away some of the ionization weakening the overall effect of static elimination. This maximized, ionized airflow with large entrained volume uses only a minimal amount of compressed air while providing a long, laminar cone of ionized air that will eliminate static charge on the target part.

In most applications only 10 psig (0.7 bar) is required to operate effectively. The Ionizing Point is a powerful ionizer which remains effective because the air exit “plastic PET head” of the unit prevents weakening if ions which metal attachments may do. This makes the Ion Blaster Beam® far more effective than systems using metal.

The Ion Blaster Beam® has a wide range of applications where a static bar with an air knife or other air support cannot be used. An example is blowing ionized air into a cavity such as a plastic container to neutralize it faster and easier, and to loosen dirt and dust stocking due to a static charge.

It is important that the compressed air supply be clean and to have a filter upstream and an automatic drain to remove unwanted moisture. If there is a possibility of oil in the air lines, an oil removal filter with an automatic drain is also recommended. And of course, a regulator to set the line pressure to the lowest level required will minimize compressed air cost.

The unit is rugged, compact, easily mountable, quiet, and uses very little compressed air. It is shockless and safe to use.

Applications

- Eliminate static charge and cleaning parts

- neutralize shrink wrap

- Form fill and seal applications for bag opening

- Neutralizing and cleaning the inside of blow molded parts

- Eliminate static and cleaning of plastic assemblies

- Dust removal from parts prior to painting

- Remove static charge in slitting applications

- Cleaning of packaging

- Neutralization of static charge inside containers.

- Advantages

-

Features / Advantages

- Effective Static Elimination

- Can clean static free dust at a distance

- Compact design to fit in small spaces

- Stand is pre-drilled for easy mounting

- Low compressed air use

- Rapid static decay

- Quiet Operation

- Shockless and non-radioactive

- Compact and rugged design

- Intake may be ducted to bring in atmospheric air from another area

- No moving parts and minimal maintenance

- Variable flow and force

- Videos

-

How The Ion Blaster Beam® Works

Compressed air is supplied at (A) where it enters the air amplifier section of the Ion Blaster Beam and follows the Coanda profile inside the amplifier. Ambient air is entrained at (B) into the amplifier. The Ionizing Point (C) ionizes the amplified airflow exiting as a powerful high flow of static removing, ionized air (D). The unit is mounted on a stand (E) for convenient installation.

- Specs

-

Specifications

Certification: North American Power Supplies certified to UL and CSA standards and Spot Ionizer used with the Ion Blaster beam is included with the certification. European Power Supplies CE approved and Spot Ionizer used with the Ion Blaster Beam is included with the certification. Stainless steel emitters on the ionizer.

Electrical: For use with 7 kV rms, 5 milliamperes (max) power supply which will last much longer than 5 kv power supplies.

Electrical Hazard: Shockless (less or equal to 5mA)

Maximum Ambient Temperature: 122 degrees F or 50 degrees C.

Part NO. Description 17040 Ion Blaster Beam® includes Air Amplifier, Spot Ionizers, Stand and 2 meters shielded cable 17140 Ion Blaster Beam® and Power Supply 17340 Ion Blaster Beam® Kit

(c/w Ion Blaster Beam®, Power supply, Model 90001 water removal filter and Model 90008 regulator with gauge)80111 120 V Power Supply, 2 outlet 80121 230 V Power Supply, 2 outlet 80112 120 V Power Supply, 4 outlet 80122 230 V Power Supply, 4 outlet 90001 Water Removal Filter c/w auto Drain 90008 Regulator with gauge - Dimensions

-

Dimensions

Ion Blaster Beam

- Power Supplies

-

Power Supplies

Ion Blaster Beam® power supplies are available in various models including a unit that will monitor the static bars for effectiveness.

Voltage Model Description 110V ENC-110/2 Two outlet (Can connect two static bars) 220V ENC-220/2 Two outlet (Can connect two static bars) 110V ENC-110/4 Four outlet (Can connect four static bars) 220V ENC-220/4 Four outlet (Can connect four static bars) 110V Multistat 110 Four outlet (Can connect four static bars, plus monitors performance. Can be connected into a system alarm or indicating light.) 220V Multistat 220 Four outlet (Can connect four) - Pricing

-

NOTE: ENC-2 Power Supply has North American electrical approval

S-Line Power Supply has CE electrical approval

Ion Blaster Beam™ PART NO. DESCRIPTION SIZE PRICE US DOLLARS 17040 ION BLASTER BEAM - $794.72 17140 ION BLASTER BEAM WITH POWER SUPPLY - $1,252.72 17140-CE ION BLASTER BEAM WITH S-LNE POWER SUPPLY - $1,500.72 17340 ION BLASTER BEAM KIT (incl 17140 plus 90001 and 90008) - $1,452.72 17340-CE ION BLASTER BEAM KIT (incl 17140 plus 90004 and 90008) - $1,700.72 More Information or Buy Here