The Patented Frigid-X® NEMA Type 4-4X-316L (IP66) Stainless Steel Panel Coolers are ideal for the pharmaceutical industry and extreme corrosive environments where 303/304 stainless steel is not adequate.

Product Overview

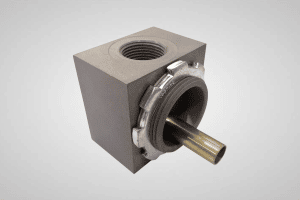

The Frigid-X® series Cabinet Enclosure Cooler for electronic control panels provides a low cost method of both purging and cooling electrical and electronic control panels by using a stainless steel vortex tube to create cold air from ordinary compressed air.

Our Cabinet Enclosure Coolers are compact and can be installed in minutes through a standard electrical knockout. They are also made from stainless steel to hold up in rain, snow, humidity, general outdoor use, and corrosive environments.

You can use our online panel cooler calculator,

or, If you would like us to do the calculation for you, or purchase consultation and we will followup with you.

If you have any questions please email: support@nexflow.com

Nex Flow® Offers 4 Types of UL Listed NEMA Rated Electrical Panel Coolers:

Frigid-X® Cabinet Panel Coolers NEMA Type 12 (IP-54) For Electronic Control Panels for General use in industrial environments where no direct liquid spray is applied to the unit.Frigid-X® Cabinet Panel Coolers NEMA Type 3R (IP-24) For Electronic Control Panels for Outdoor Use.

Frigid-X® Panel Coolers NEMA Type 4-4X (IP-66) For Electronic Control Panels – splash resistant, for use in washdown environments as well as outdoor use. Unique patented design * for secure watertight protection. Frigid-X® Panel Coolers NEMA Type 4-4X-316L (IP-66) The Patented* NEMA TYPE 4-4X-316L (IP 66) Frigid-X® Panel Cooler are constructed of 316L Stainless Steel. Dust, oil-tight,spray resistant and used in environments where there are liquids and for food service and corrosive environments.

* US patent number 8,616,010 / Other countries: Patented or Patent Pending

Note: Always question non-approved units used on electrical enclosures to assure that your panels are not damaged by inferior products.

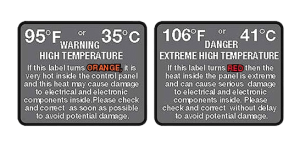

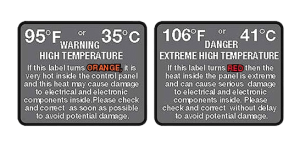

Nex Flow® offers a High Temperature Warning Sticker free with every Frigid-X® Panel Cooler purchased for the air conditioning of electrical and electronic control panels. High temperature inside a control panel can be damaging to internal equipment and lead to unplanned shutdown of factory operations. The label provides for an effective warning with a color change indicator to ORANGE and a danger warning with a color change indicator to RED. Color change is reversible so when the temperature problem is corrected, the label can continue to be used indefinitely. While it is a qualitative measurement only, it provides an ideal cautionary monitoring of possible temperature problems within a control panel.

Features / Advantages

- Low in cost

- Compact

- No CFCs

- Fast installation

- Stabilize enclosure temperature and humidity

- Virtually maintenance free (No Moving Parts)

- Mounts in a standard electrical knockout

- Stops heat damage and nuisance tripping

- Eliminates fans and filters

- Prevents dirt contamination by keeping enclosure at positive pressure

- Units applicable to all environments including high temperature to 200ºF

Videos

How Cabinet Panel Coolers Work

Overheating electrical and electronic control panels cause plant shutdowns and costly maintenance issues if not addressed. In many cases regular air conditioning is adequate to address cooling. But some factory environments are better suited to vortex tube operated systems such as the Frigid-XTM Panel Cooler. If you find that your air conditioners are breaking down often because of a nasty factory environment or high vibration causing damage or frequent service and recharging, or if filters require frequent change (and disposal which is an extra cost) then these cooling systems are economical to use.

Compressed air enters at point (A) into the vortex tube component of the panel cooler. The vortex tube splits the compressed air into a hot (B) and cold (C) stream of air. The hot air from the vortex tube is vented to the atmosphere at point (D) after being muffled to reduce noise. Hot air is displaced from inside the cabinet enclosure and exhausted through point (E) via a built in venting system. Cold air enters into the panel at point (F) and distributed via the cold distribution hose (G). Holes (H) are punched into the hose kit to deliver the cold air inside the panel cooler where cooling is required the most. A muffler (I) at the end of the hose further reduces the noise level of the cooled air.

The Frigid-X® Panel Coolers are all RUL tested and approved with three NEMA ratings with equivalent IP rating for other countries – NEMA 12 (IP 54) versions for most control panels, NEMA 3R (IP 24) for outside use, and NEMA 4-4X (IP 66) for corrosive atmospheres. Material is normally 304 stainless bit 316L stainless steel versions also available if required.

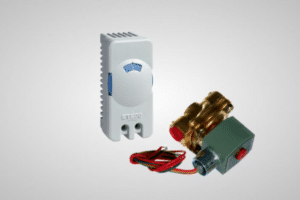

Normally Panel Coolers are mounted on the top of control cabinets but if there is no room, side mount systems are available. A Thermostat and Solenoid valve package or Electronic Control System will turn the Panel Cooler on or off as required saving compressed air. In very dirty environments, where a small amount of compressed flow is desired in the enclosure for purging (to keep out a dirty environment) and optional ByPass System is available.

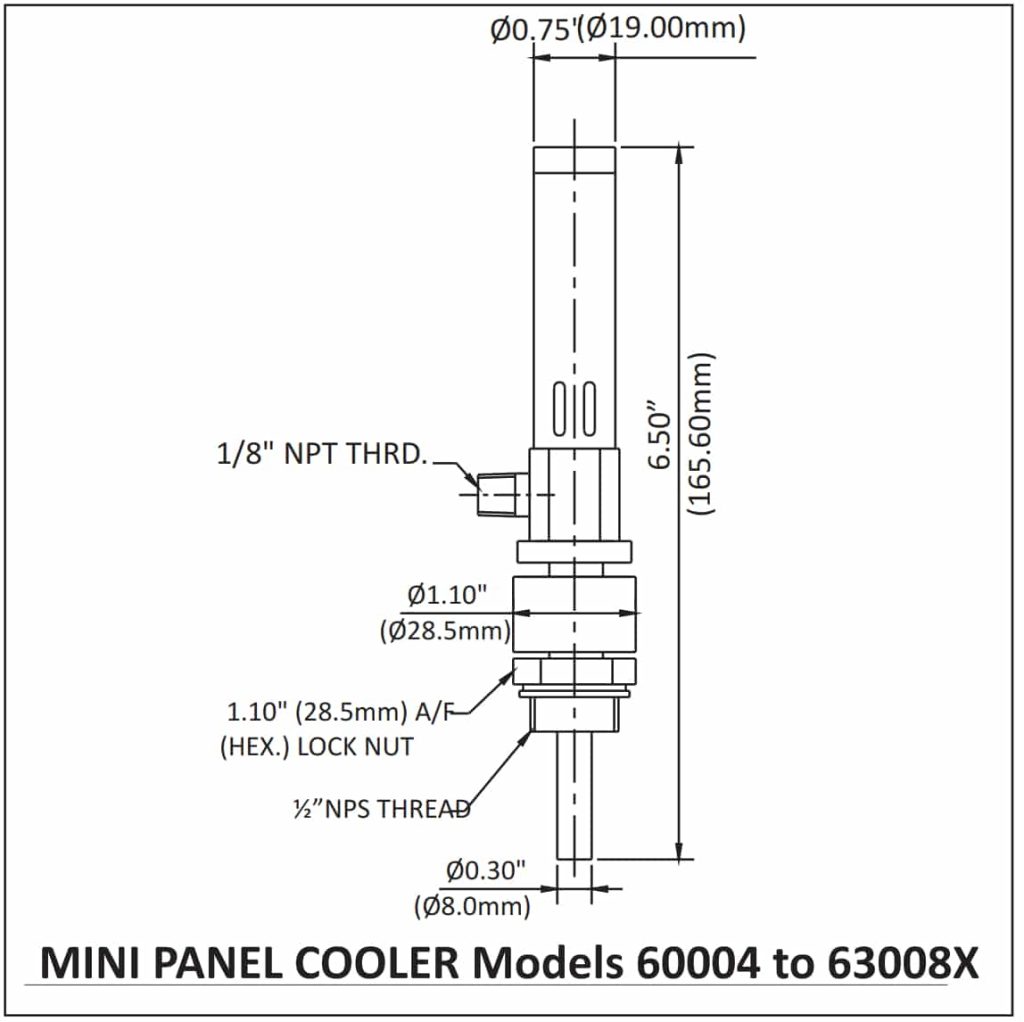

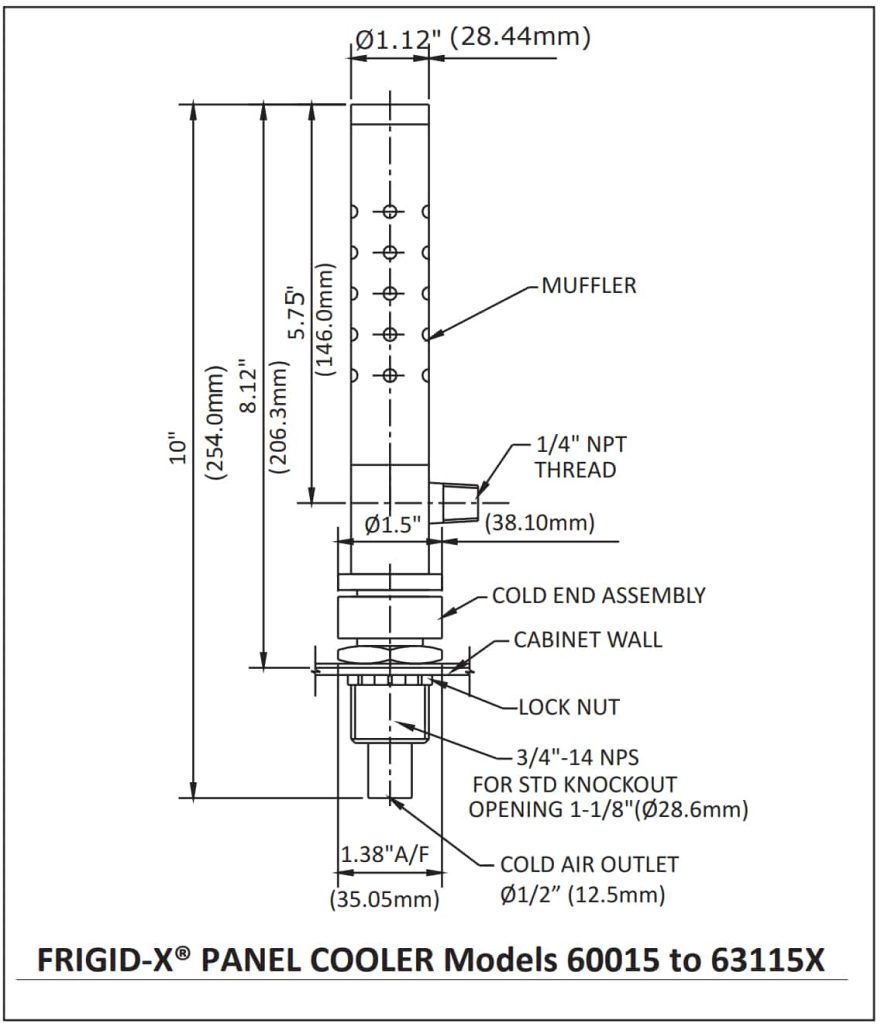

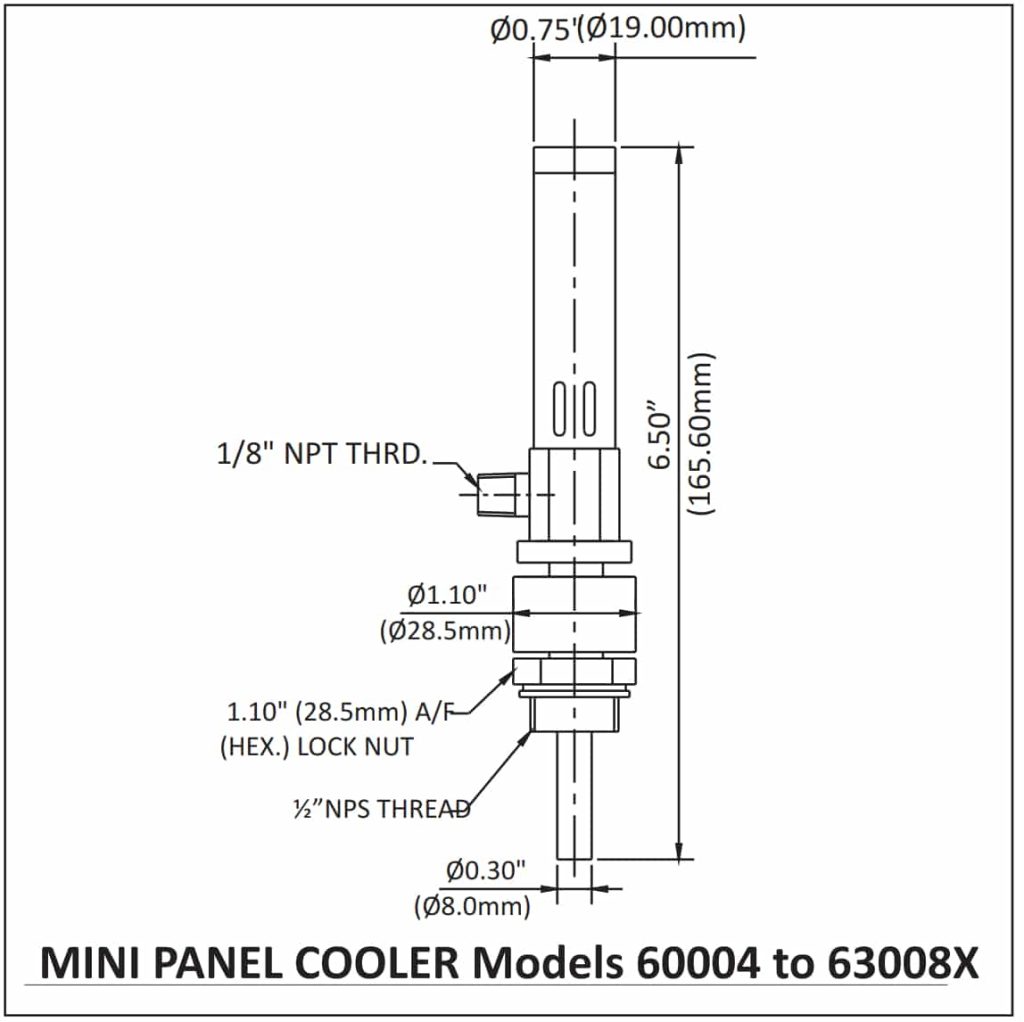

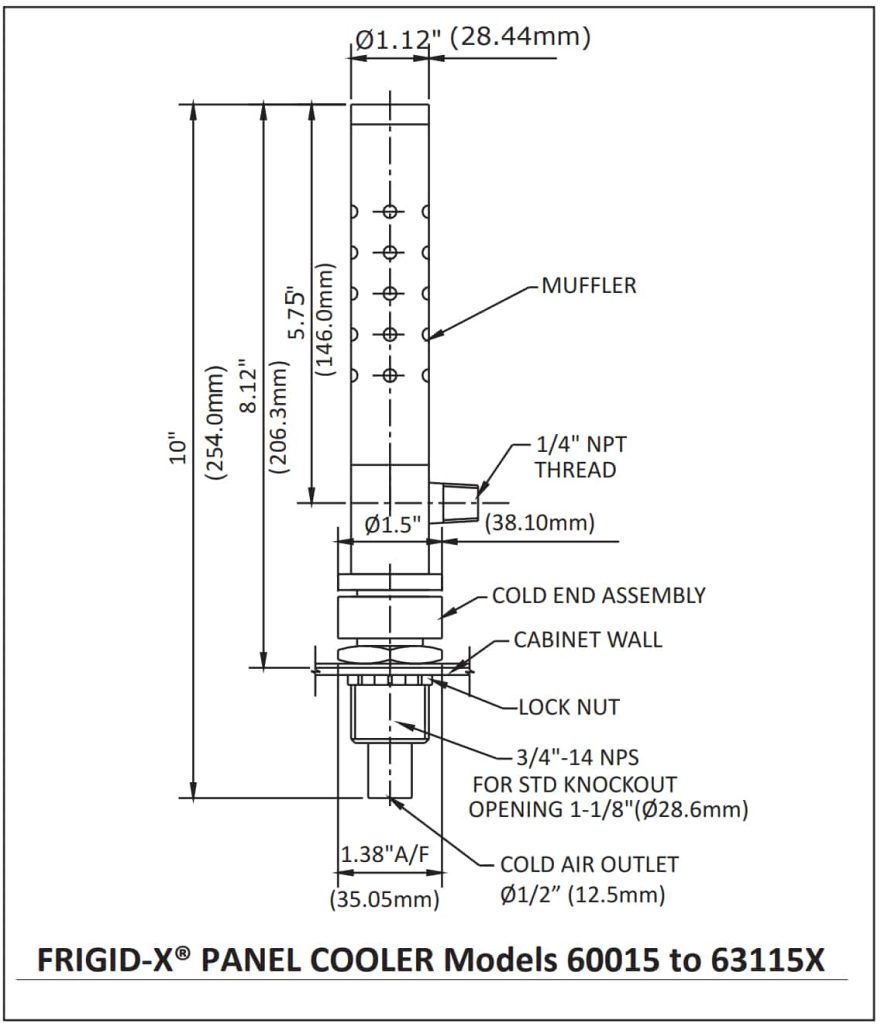

Dimensions

Selection

Cabinet enclosure coolers come with a 5 micron filter with an automatic drain (except for the 316L stainless steel units) for the compressed air supply to insure clean, dry air and an air distribution kit to circulate the cold air inside the enclosure for even cooling.

Cabinet enclosure coolers come with a 5 micron filter with an automatic drain (except for the 316L stainless steel units) for the compressed air supply to insure clean, dry air and an air distribution kit to circulate the cold air inside the enclosure for even cooling.

Cabinet enclosure coolers are available with or without thermostat control.

When constant cooling and a constant positive purge is required we recommend the continuous operating version without the thermostat and solenoid valve. The cooling effect can be controlled by adding a regulator in line to reduce pressure for reduced cooling when it is not required and to conserve energy.

Systems utilizing a thermostat and solenoid valve saves air by activating the air conditioner only when the internal temperature reaches a critical level. The adjustable thermostat is factory set at 95°F but can be readjusted on site.

Thermostat and solenoid valve systems are recommended where the heat load can fluctuate (such as for frequency drives) and where a continual purge is not required. The thermostat and solenoid “package” can also be added at a later date to a continuous system. An Electronic Thermostat System is also available replacing the thermostat and solenoid valve with a control box to “set” the temperature (ELC System).

If mounting cannot be on the top of the control panel an optional side mount is available (except or the 316L stainless units). Panel Coolers must be mounted vertical either at the top or at the side using the side mount.

You can use our online panel cooler calculator,

or, If you would like us to do the calculation for you, or purchase consultation and we will followup with you.

If you have any questions please email: support@nexflow.com

Contact Nex Flow® for assistance in sizing cabinet enclosure cooler – Frigid-X® series. See Below for Sizing Specifications

| MODEL NO. | VERSION | BTU/Hr. cooling*(WATTS) | dBA at 80 PSIG (5.5 bar) |

|---|---|---|---|

| 61004A | NEMA Type 12 (IP-54) Continuous Operation | 290 (85) | 64 |

| 61008A | NEMA Type 12 (IP-54) Continuous Operation | 580 (170) | 66 |

| 61015A | NEMA Type 12 (IP-54) Continuous Operation | 1100 (322) | 72 |

| 61025A | NEMA Type 12 (IP-54) Continuous Operation | 1800 (527) | 73 |

| 61030A | NEMA Type 12 (IP-54) Continuous Operation | 2100 (615) | 74 |

| 61040A | NEMA Type 12 (IP-54) Continuous Operation | 2900 (849) | 76 |

| 63004A | NEMA Type 12 (IP-54) Continuous Operation | 290 (85) | 64 |

| 63008A | NEMA Type 12 (IP-54) on-off control | 580 (170) | 66 |

| 63015A | NEMA Type 12 (IP-54) on-off control | 1100 (322) | 72 |

| 63025A | NEMA Type 12 (IP-54) on-off control | 1800 (527) | 73 |

| 63030A | NEMA Type 12 (IP-54) on-off control | 2100 (615) | 74 |

| 63040A | NEMA Type 12 (IP-54) on-off control | 2900 (849) | 76 |

| 61004R | NEMA Type 3R (IP-24) Continuous Operation | 290 (85) | 64 |

| 61008R | NEMA Type 3R (IP-24) Continuous Operation | 580 (170) | 66 |

| 61015R | NEMA Type 3R (IP-24) Continuous Operation | 1100 (322) | 72 |

| 61025R | NEMA Type 3R (IP-24) Continuous Operation | 1800 (527) | 73 |

| 61030R | NEMA Type 3R (IP-24) Continuous Operation | 2100 (615) | 74 |

| 61040R | NEMA Type 3R (IP-24) Continuous Operation | 2900 (849) | 76 |

| 63004R | NEMA Type 3R (IP-24) on-off control | 290 (85) | 64 |

| 63008R | NEMA Type 3R (IP-24) on-off control | 580 (170) | 66 |

| 63015R | NEMA Type 3R (IP-24) on-off control | 1100 (322) | 72 |

| 63025R | NEMA Type 3R (IP-24) on-off control | 21800 (527) | 73 |

| 63030R | NEMA Type 3R (IP-24) on-off control | 2100 (615) | 74 |

| 63040R | NEMA Type 3R (IP-24) on-off control | 2900 (849) | 76 |

| 61104X | NEMA Type 4-4X (IP-66) Continuous Operation | 290 (85) | 64 |

| 61108X | NEMA Type 4-4X (IP-66) Continuous Operation | 580 (170) | 66 |

| 61115X | NEMA Type 4-4X (IP-66) Continuous Operation | 1100 (322) | 72 |

| 61125X | NEMA Type 4-4X (IP-66) Continuous Operation | 1800 (527) | 73 |

| 61130X | NEMA Type 4-4X (IP-66) Continuous Operation | 2100 (615) | 74 |

| 61140X | NEMA Type 4-4X (IP-66) Continuous Operation | 2900 (849) | 76 |

| 63104X | NEMA type 4-4X (IP-66) on-off control | 290 (85) | 64 |

| 63108X | NEMA Type 4-4X (IP-66) on-off control | 580 (170) | 66 |

| 63115X | NEMA Type 4-4X (IP-66) on-off control | 1100 (322) | 72 |

| 63125X | NEMA Type 4-4X (IP-66) on-off control | 1800 (527) | 73 |

| 63130X | NEMA Type 4-4X (IP-66) on-off control | 2100 (615) | 74 |

| 63140X | NEMA Type 4-4X (IP-66) on-off control | 2900 (849) | 76 |

| 60115X-316L | 316 L Stainless Steel NEMA Type 4-4X (IP-66) on-off control (customer supplies own filter)** | 1100 (322) | 72 |

| 60125X-316L | 316 L Stainless Steel NEMA Type 4-4X (IP-66) on-off control (customer supplies own filter)** | 21800 (527) | 73 |

| 60130X-316L | 316 L Stainless Steel NEMA Type 4-4X (IP-66) on-off control (customer supplies own filter)** | 2100 (615) | 74 |

| 60140X-316L | 316 L Stainless Steel NEMA Type 4-4X (IP-66) on-off control (customer supplies own filter)** | 2900 (849) | 76 |

** In 316 environments customers will normally have special filtration systems already in place.

*Cooling effect based on 95°F temperature inside cabinet, 100 PSIG (6.9 BAR) compressor inlet pressure, and 70ºF (21ºC) inlet temperature.

BTU/hr. figures rounded to nearest 100 BTU/hr (1 WATT).

All Continuous Operation models include the cooling unit, filter with auto drain and cold air distribution kit.

All On-Off control units include the cooling unit, filter with auto drain, cold air distribution kit, solenoid valve and thermostat.

Calculating Head Load

You can use our online panel cooler calculator,

or, If you would like us to do the calculation for you, or purchase consultation and we will followup with you.

If you have any questions please email: support@nexflow.com

Total heat load consists of the heat transfer from outside your panel and from the heat dissipated inside the control unit.

Useful terms and conversions:

1 BTU/hr = 0.293 watts

1 BTU/hr – 0.000393 horsepower

1 Watt = 3.415 BTU/hr

1 horsepower = 2544 BTU/hr

1 Watt = 0.00134 horsepower

1 Square Foot = 0.0929 square meters

1 Square Meter = 10.76 square foot

Typical fan capacity:

4″ fan: 100 CFM (2832 LPM)

6″ fan: 220 CFM (6230 LPM)

8″ fan: 340 CFM (9628 LPM)

10″ fan 550 CFM (15574 LPM)

BTU/hr. cooling effect from fan 1.08 x (temp. inside panel in °F – temp. outside panel in degrees F) x CFM.

Watts cooling effect from fan: 0.20 x (temp. inside panel in °C – temp. outside panel in degrees C) x LPM.

Calculating BTU/hr. or Watts:

- Determine the heat generated inside the enclosure. Approximations may be necessary. For example, if you know the power generated inside the unit, assume 10% of the energy is dissipated as heat.

- For heat transfer from the outside, calculate the area exposed to the atmosphere except for the top of the control panel.

- Choose the internal temperature you wish to have, and choose the temperature difference between it and the maximum external temperature expected.

- From the conversion table that follows, determine the BTU/hr. per square foot (or watts per square meter) for the temperature difference.

- Multiply the panel surface area times the BTU/hr. per square foot (or watts per square meter) to get the external heat transfer in BTU/hr or in watts.

- Sum the internal and external heat loads calculated.

- If you do not know the power used in the enclosure but you can measure temperatures, then measure the temperature difference between the outside at current temperature, and the present internal cabinet temperature.

- Note size and number of any external fans. Provide this information to Nex Flow® to assist in sizing the appropriate cooling system.

| Temperature Difference in °F | BTU/hr./sq. ft. | Temperature Difference in °C | Watts/sq.m |

|---|---|---|---|

| 5 | 1.5 | 3 | 5.2 |

| 10 | 3.3 | 6 | 11.3 |

| 15 | 5.1 | 9 | 17.6 |

| 20 | 7.1 | 12 | 24.4 |

| 25 | 9.1 | 15 | 31.4 |

| 30 | 11.3 | 18 | 39.5 |

| 35 | 13.8 | 21 | 47.7 |

| 40 | 16.2 | 24 | 55.6 |

Example:

The control panel cooler has two frequency drives totaling 10 horsepower and one module rated at 100 watts. The maximum outside temperature expected is 105°F or 40.5°C. The area of the control panel cooler exposed sides, except for the top is 42 square feet or 3.9 square meters. We want the internal temperature to be 95° or 35°C.

Total internal power is 10 hp x 746 watts/hp – 7460 plus 100 watts = 7560 watts.

Assume 10% forms heat = an internal heat load of 756 watts.

Or

Total internal power is 10 hp x 2544 BTU/hp = 25440 BTU/hr plus 100 watts x 3.415 BTU/hr/watt = 25782 BTU/hr.

Assume 10% forms heat = an internal heat load of 2578 BTU/hr.

External heat load: The temperature difference between the desired temperature and the outside is 10°F or 5.5°C. Using the conversions (and interpolating where necessary) we multiply the area by the conversion factor:

42 sq. ft x 3.3 – 139 BTU/hr or 3.9 sq. m x 10.3 = 40 watts

Total Heat Load: 756 + 40 – 796 watts or 2578 + 139 – 2717 BTU/hr.

You would use a Model 61040 for constant operation or a Model 63040 for one-off control. (Rated at 2900 BTU/hr or 849 watts).

| Panel Coolers | ||

|---|---|---|

| PART NO. | DESCRIPTION | PRICE US DOLLARS |

| 60002A | NEMA 12 FRIGID-X Enclosure Cooler Only | $350.00 |

| 60004A | NEMA 12 FRIGID-X Enclosure Cooler Only | $350.00 |

| 60008A | NEMA 12 FRIGID-X Enclosure Cooler Only | $350.00 |

| 60010A | NEMA 12 FRIGID-X Enclosure Cooler Only | $430.00 |

| 60015A | NEMA 12 FRIGID-X Enclosure Cooler Only | $430.00 |

| 60025A | NEMA 12 FRIGID-X Enclosure Cooler Only | $430.00 |

| 60030A | NEMA 12 FRIGID-X Enclosure Cooler Only | $430.00 |

| 60040A | NEMA 12 FRIGID-X Enclosure Cooler Only | $430.00 |

| 60002R | NEMA 3R FRIGID-X Enclosure Cooler Only | $365.00 |

| 60004R | NEMA 3R FRIGID-X Enclosure Cooler Only | $365.00 |

| 60008R | NEMA 3R FRIGID-X Enclosure Cooler Only | $365.00 |

| 60010R | NEMA 3R FRIGID-X Enclosure Cooler Only | $445.00 |

| 60015R | NEMA 3R FRIGID-X Enclosure Cooler Only | $445.00 |

| 60025R | NEMA 3R FRIGID-X Enclosure Cooler Only | $445.00 |

| 60030R | NEMA 3R FRIGID-X Enclosure Cooler Only | $445.00 |

| 60040R | NEMA 3R FRIGID-X Enclosure Cooler Only | $445.00 |

| 60102X | NEMA 4-4X FRIGID-X Enclosure Cooler Only | $471.00 |

| 60104X | NEMA 4-4X FRIGID-X Enclosure Cooler Only | $471.00 |

| 60108X | NEMA 4-4X FRIGID-X Enclosure Cooler Only | $471.00 |

| 60110X | NEMA 4-4X FRIGID-X Enclosure Cooler Only | $496.00 |

| 60115X | NEMA 4-4X FRIGID-X Enclosure Cooler Only | $496.00 |

| 60125X | NEMA 4-4X FRIGID-X Enclosure Cooler Only | $496.00 |

| 60130X | NEMA 4-4X FRIGID-X Enclosure Cooler Only | $496.00 |

| 60140X | NEMA 4-4X FRIGID-X Enclosure Cooler Only | $496.00 |

| 60102X-316L | NEMA 4-4X FRIGID-X 316L Stainless Enclosure Cooler Only | $942.00 |

| 60104X-316L | NEMA 4-4X FRIGID-X 316L Stainless Enclosure Cooler Only | $942.00 |

| 60108X-316L | NEMA 4-4X FRIGID-X 316L Stainless Enclosure Cooler Only | $942.00 |

| 60110X-316L | NEMA 4-4X FRIGID-X 316L Stainless Enclosure Cooler Only | $992.00 |

| 60115X-316L | NEMA 4-4X FRIGID-X 316L Stainless Enclosure Cooler Only | $992.00 |

| 60125X-316L | NEMA 4-4X FRIGID-X 316L Stainless Enclosure Cooler Only | $992.00 |

| 60130X-316L | NEMA 4-4X FRIGID-X 316L Stainless Enclosure Cooler Only | $992.00 |

| 60140X-316L | NEMA 4-4X FRIGID-X 316L Stainless Enclosure Cooler Only | $992.00 |

| 60002AD | NEMA 12 FRIGID-X Enclosure Cooler Only + hose kit (69005) | $385.00 |

| 60004AD | NEMA 12 FRIGID-X Enclosure Cooler Only + hose kit (69005) | $385.00 |

| 60008AD | NEMA 12 FRIGID-X Enclosure Cooler Only + hose kit (69005) | $385.00 |

| 60010AD | NEMA 12 FRIGID-X Enclosure Cooler Only + hose kit (69004) | $472.00 |

| 60015AD | NEMA 12 FRIGID-X Enclosure Cooler Only + hose kit (69004) | $472.00 |

| 60025AD | NEMA 12 FRIGID-X Enclosure Cooler Only + hose kit (69004) | $472.00 |

| 60030AD | NEMA 12 FRIGID-X Enclosure Cooler Only + hose kit (69004) | $472.00 |

| 60040AD | NEMA 12 FRIGID-X Enclosure Cooler Only + hose kit (69004) | $472.00 |

| 60002RD | NEMA 3R FRIGID-X Enclosure Cooler Only + hose kit (69005) | $400.00 |

| 60004RD | NEMA 3R FRIGID-X Enclosure Cooler Only + hose kit (69005) | $400.00 |

| 60008RD | NEMA 3R FRIGID-X Enclosure Cooler Only + hose kit (69005) | $400.00 |

| 60010RD | NEMA 3R FRIGID-X Enclosure Cooler Only + hose kit (69004) | $487.00 |

| 60015RD | NEMA 3R FRIGID-X Enclosure Cooler Only + hose kit (69004) | $487.00 |

| 60025RD | NEMA 3R FRIGID-X Enclosure Cooler Only + hose kit (69004) | $487.00 |

| 60030RD | NEMA 3R FRIGID-X Enclosure Cooler Only + hose kit (69004) | $487.00 |

| 60040RD | NEMA 3R FRIGID-X Enclosure Cooler Only + hose kit (69004) | $487.00 |

| 60102XD | NEMA 4-4X FRIGID-X Enclosure Cooler Only + hose kit (69005) | $506.00 |

| 60104XD | NEMA 4-4X FRIGID-X Enclosure Cooler Only + hose kit (69005) | $506.00 |

| 60108XD | NEMA 4-4X FRIGID-X Enclosure Cooler Only + hose kit (69005) | $506.00 |

| 60110XD | NEMA 4-4X FRIGID-X Enclosure Cooler Only + hose kit (69004) | $538.00 |

| 60115XD | NEMA 4-4X FRIGID-X Enclosure Cooler Only + hose kit (69004) | $538.00 |

| 60125XD | NEMA 4-4X FRIGID-X Enclosure Cooler Only + hose kit (69004) | $538.00 |

| 60130XD | NEMA 4-4X FRIGID-X Enclosure Cooler Only + hose kit (69004) | $538.00 |

| 60140XD | NEMA 4-4X FRIGID-X Enclosure Cooler Only + hose kit (69004) | $538.00 |

| 60102X-316L-D | NEMA 4-4X FRIGID-X 316L Stainless Cooler + hose kit (69005) | $977.00 |

| 60102X-316L-D | NEMA 4-4X FRIGID-X 316L Stainless Cooler + hose kit (69005) | $977.00 |

| 60102X-316L-D | NEMA 4-4X FRIGID-X 316L Stainless Cooler + hose kit (69005) | $977.00 |

| 60110X-316L-D | NEMA 4-4X FRIGID-X 316L Stainless Cooler + hose kit (69004) | $1,034.00 |

| 60115X-316L-D | NEMA 4-4X FRIGID-X 316L Stainless Cooler + hose kit (69004) | $1,034.00 |

| 60125X-316L-D | NEMA 4-4X FRIGID-X 316L Stainless Cooler + hose kit (69004) | $1,034.00 |

| 60130X-316L-D | NEMA 4-4X FRIGID-X 316L Stainless Cooler + hose kit (69004) | $1,034.00 |

| 60140X-316L-D | NEMA 4-4X FRIGID-X 316L Stainless Cooler + hose kit (69004) | $1,034.00 |

| 61002A | NEMA 12 FRIGID-X Enclosure Cooler Only + hose kit + filter (90004) – continuous system | $484.00 |

| 61004A | NEMA 12 FRIGID-X Enclosure Cooler Only + hose kit + filter (90004) – continuous system | $484.00 |

| 61008A | NEMA 12 FRIGID-X Enclosure Cooler Only + hose kit + filter (90004) – continuous system | $484.00 |

| 61010A | NEMA 12 FRIGID-X Enclosure Cooler Only + hose kit + filter (90004) – continuous system | $597.00 |

| 61015A | NEMA 12 FRIGID-X Enclosure Cooler Only + hose kit + filter (90004) – continuous system | $597.00 |

| 61025A | NEMA 12 FRIGID-X Enclosure Cooler Only + hose kit + filter (90004) – continuous system | $597.00 |

| 61030A | NEMA 12 FRIGID-X Enclosure Cooler Only + hose kit + filter (90004) – continuous system | $597.00 |

| 61040A | NEMA 12 FRIGID-X Enclosure Cooler Only + hose kit + filter (90004) – continuous system | $597.00 |

| 61002R | NEMA 3R FRIGID-X Enclosure Cooler Only + hose kit + filter (90004) – continuous system | $499.00 |

| 61004R | NEMA 3R FRIGID-X Enclosure Cooler Only + hose kit + filter (90004) – continuous system | $499.00 |

| 61008R | NEMA 3R FRIGID-X Enclosure Cooler Only + hose kit + filter (90004) – continuous system | $499.00 |

| 61010R | NEMA 3R FRIGID-X Enclosure Cooler Only + hose kit + filter (90004) – continuous system | $612.00 |

| 61015R | NEMA 3R FRIGID-X Enclosure Cooler Only + hose kit + filter (90004) – continuous system | $612.00 |

| 61025R | NEMA 3R FRIGID-X Enclosure Cooler Only + hose kit + filter (90004) – continuous system | $612.00 |

| 61030R | NEMA 3R FRIGID-X Enclosure Cooler Only + hose kit + filter (90004) – continuous system | $612.00 |

| 61040R | NEMA 3R FRIGID-X Enclosure Cooler Only + hose kit + filter (90004) – continuous system | $612.00 |

| 61102X | NEMA 4-4X FRIGID-X Enclosure Cooler Only + hose kit + filter (90007) – continuous system | $631.00 |

| 61104X | NEMA 4-4X FRIGID-X Enclosure Cooler Only + hose kit + filter (90007) – continuous system | $631.00 |

| 61108X | NEMA 4-4X FRIGID-X Enclosure Cooler Only + hose kit + filter (90007) – continuous system | $631.00 |

| 61110X | NEMA 4-4X FRIGID-X Enclosure Cooler Only + hose kit + filter (90007) – continuous system | $663.00 |

| 61115X | NEMA 4-4X FRIGID-X Enclosure Cooler Only + hose kit + filter (90007) – continuous system | $663.00 |

| 61125X | NEMA 4-4X FRIGID-X Enclosure Cooler Only + hose kit + filter (90007) – continuous system | $663.00 |

| 61130X | NEMA 4-4X FRIGID-X Enclosure Cooler Only + hose kit + filter (90007) – continuous system | $663.00 |

| 61140X | NEMA 4-4X FRIGID-X Enclosure Cooler Only + hose kit + filter (90007) – continuous system | $663.00 |

| 63002A | NEMA 12 FRIG-X Cl. + hose kit + filter + therm. (90017) & sol.(90020) – on/off control standard thermostat | $860.00 |

| 63004A | NEMA 12 FRIG-X Cl. + hose kit + filter + therm. (90017) & sol.(90020) – on/off control standard thermostat | $860.00 |

| 63008A | NEMA 12 FRIG-X Cl. + hose kit + filter + therm. (90017) & sol.(90020) – on/off control standard thermostat | $860.00 |

| 63010A | NEMA 12 FRIG-X Cl. + hose kit + filter + therm. (90017) & sol.(90020) – on/off control standard thermostat | $973.00 |

| 63015A | NEMA 12 FRIG-X Cl. + hose kit + filter + therm. (90017) & sol.(90020) – on/off control standard thermostat | $973.00 |

| 63025A | NEMA 12 FRIG-X Cl. + hose kit + filter + therm. (90017) & sol.(90020) – on/off control standard thermostat | $973.00 |

| 63030A | NEMA 12 FRIG-X Cl. + hose kit + filter + therm. (90017) & sol.(90020) – on/off control standard thermostat | $973.00 |

| 63040A | NEMA 12 FRIG-X Cl. + hose kit + filter + therm. (90017) & sol.(90020) – on/off control standard thermostat | $973.00 |

| 63002R | NEMA 3R FRIG-X Cl. + hose kit + filter + therm. (90017) & sol.(90020) – on/off control standard thermostat | $875.00 |

| 63004R | NEMA 3R FRIG-X Cl. + hose kit + filter + therm. (90017) & sol.(90020) – on/off control standard thermostat | $875.00 |

| 63008R | NEMA 3R FRIG-X Cl. + hose kit + filter + therm. (90017) & sol.(90020) – on/off control standard thermostat | $875.00 |

| 63010R | NEMA 3R FRIG-X Cl. + hose kit + filter + therm. (90017) & sol.(90020) – on/off control standard thermostat | $988.00 |

| 63015R | NEMA 3R FRIG-X Cl. + hose kit + filter + therm. (90017) & sol.(90020) – on/off control standard thermostat | $988.00 |

| 63025R | NEMA 3R FRIG-X Cl. + hose kit + filter + therm. (90017) & sol.(90020) – on/off control standard thermostat | $988.00 |

| 63030R | NEMA 3R FRIG-X Cl. + hose kit + filter + therm. (90017) & sol.(90020) – on/off control standard thermostat | $988.00 |

| 63040R | NEMA 3R FRIG-X Cl. + hose kit + filter + therm. (90017) & sol.(90020) – on/off control standard thermostat | $988.00 |

| 63102X | NEMA 4-4X FRIG-X Encl. Cl. + hs kit + fr + ther. (90017) & sol.(90018) – on/off control standard thermostat | $1,007.00 |

| 63104X | NEMA 4-4X FRIG-X Encl. Cl. + hs kit + fr + ther. (90017) & sol.(90018) – on/off control standard thermostat | $1,007.00 |

| 63108X | NEMA 4-4X FRIG-X Encl. Cl. + hs kit + fr + ther. (90017) & sol.(90018) – on/off control standard thermostat | $1,007.00 |

| 63110X | NEMA 4-4X FRIG-X Encl. Cl. + hs kit + fr + ther. (90017) & sol.(90018) – on/off control standard thermostat | $1,039.00 |

| 63115X | NEMA 4-4X FRIG-X Encl. Cl. + hs kit + fr + ther. (90017) & sol.(90018) – on/off control standard thermostat | $1,039.00 |

| 63125X | NEMA 4-4X FRIG-X Encl. Cl. + hs kit + fr + ther. (90017) & sol.(90018) – on/off control standard thermostat | $1,039.00 |

| 63130X | NEMA 4-4X FRIG-X Encl. Cl. + hs kit + fr + ther. (90017) & sol.(90018) – on/off control standard thermostat | $1,039.00 |

| 63140X | NEMA 4-4X FRIG-X Encl. Cl. + hs kit + fr + ther. (90017) & sol.(90018) – on/off control standard thermostat | $1,039.00 |

| 63002A-ELC | NEMA 12 FRIG-X Cl. + hose kit + filter + ELECTRONIC CONTROL PACKAGED SYSTEM | $1,465.00 |

| 63004A-ELC | NEMA 12 FRIG-X Cl. + hose kit + filter + ELECTRONIC CONTROL PACKAGED SYSTEM | $1,465.00 |

| 63008A-ELC | NEMA 12 FRIG-X Cl. + hose kit + filter + ELECTRONIC CONTROL PACKAGED SYSTEM | $1,465.00 |

| 63010A-ELC | NEMA 12 FRIG-X Cl. + hose kit + filter + ELECTRONIC CONTROL PACKAGED SYSTEM | $1,578.00 |

| 63015A-ELC | NEMA 12 FRIG-X Cl. + hose kit + filter + ELECTRONIC CONTROL PACKAGED SYSTEM | $1,578.00 |

| 63025A-ELC | NEMA 12 FRIG-X Cl. + hose kit + filter + ELECTRONIC CONTROL PACKAGED SYSTEM | $1,578.00 |

| 63030A-ELC | NEMA 12 FRIG-X Cl. + hose kit + filter + ELECTRONIC CONTROL PACKAGED SYSTEM | $1,578.00 |

| 63040A-ELC | NEMA 12 FRIG-X Cl. + hose kit + filter + ELECTRONIC CONTROL PACKAGED SYSTEM | $1,578.00 |

| 63002R-ELC | NEMA 3RFRIG-X Cl. + hose kit + filter + ELECTRONIC CONTROL PACKAGED SYSTEM | $1,480.00 |

| 63004R-ELC | NEMA 3RFRIG-X Cl. + hose kit + filter + ELECTRONIC CONTROL PACKAGED SYSTEM | $1,480.00 |

| 63008R-ELC | NEMA 3RFRIG-X Cl. + hose kit + filter + ELECTRONIC CONTROL PACKAGED SYSTEM | $1,480.00 |

| 63010R-ELC | NEMA 3RFRIG-X Cl. + hose kit + filter + ELECTRONIC CONTROL PACKAGED SYSTEM | $1,593.00 |

| 63015R-ELC | NEMA 3RFRIG-X Cl. + hose kit + filter + ELECTRONIC CONTROL PACKAGED SYSTEM | $1,593.00 |

| 63025R-ELC | NEMA 3RFRIG-X Cl. + hose kit + filter + ELECTRONIC CONTROL PACKAGED SYSTEM | $1,593.00 |

| 63030R-ELC | NEMA 3RFRIG-X Cl. + hose kit + filter + ELECTRONIC CONTROL PACKAGED SYSTEM | $1,593.00 |

| 63040R-ELC | NEMA 3RFRIG-X Cl. + hose kit + filter + ELECTRONIC CONTROL PACKAGED SYSTEM | $1,593.00 |

| 63102X-ELC | NEMA 4-4X FRIG-X Encl. Cl. + hose kit + filter + ELECTR. CONTROL PACKAGED SYSTEM | $1,612.00 |

| 63104X-ELC | NEMA 4-4X FRIG-X Encl. Cl. + hose kit + filter + ELECTR. CONTROL PACKAGED SYSTEM | $1,612.00 |

| 63108X-ELC | NEMA 4-4X FRIG-X Encl. Cl. + hose kit + filter + ELECTR. CONTROL PACKAGED SYSTEM | $1,612.00 |

| 63110X-ELC | NEMA 4-4X FRIG-X Encl. Cl. + hose kit + filter + ELECTR. CONTROL PACKAGED SYSTEM | $1,644.00 |

| 63115X-ELC | NEMA 4-4X FRIG-X Encl. Cl. + hose kit + filter + ELECTR. CONTROL PACKAGED SYSTEM | $1,644.00 |

| 63125X-ELC | NEMA 4-4X FRIG-X Encl. Cl. + hose kit + filter + ELECTR. CONTROL PACKAGED SYSTEM | $1,644.00 |

| 63130X-ELC | NEMA 4-4X FRIG-X Encl. Cl. + hose kit + filter + ELECTR. CONTROL PACKAGED SYSTEM | $1,644.00 |

| 63140X-ELC | NEMA 4-4X FRIG-X Encl. Cl. + hose kit + filter + ELECTR. CONTROL PACKAGED SYSTEM | $1,644.00 |

| More Information or Buy Here |

| Frigid-X™ By-Pass System for Panel cooler | ||

|---|---|---|

| PART NO. | DESCRIPTION | PRICE US DOLLARS |

| 69700 | Bypass System to make a constant purge system – One system for each cooler is necessary | $250.00 |

| More Information or Buy Here |

| Muffling Kits for Panel Coolers | ||

|---|---|---|

| PART NO. | DESCRIPTION | PRICE US DOLLARS |

| 69501 | Cold End Muffler Kit for 10 to 40 SCFM Panel Cooler Units | $100.00 |

| 69502 | Hot End Muffler & Heat Guard Kit for 10 to 40 SCFM Panel Cooler Units | $100.00 |

| 69503 | Cold End Muffler Kit for 2 to 8 SCFM Panel Cooler Units | $95.00 |

| 69504 | Hot End Muffler & Heat Guard Kit for 2 to 8 SCFM Panel Cooler Units | $95.00 |

| 69505 | Hot and Cold End Muffler & Heat Guard Kit for 10 to 40 SCFM Panel Cooler Units | $200.00 |

| 69506 | Hot and Cold End Muffler & Heat Guard Kit for 2 to 8 SCFM Panel Cooler Units | $190.00 |

| More Information or Buy Here |

- Overview

-

Product Overview

The Frigid-X® series Cabinet Enclosure Cooler for electronic control panels provides a low cost method of both purging and cooling electrical and electronic control panels by using a stainless steel vortex tube to create cold air from ordinary compressed air.

Our Cabinet Enclosure Coolers are compact and can be installed in minutes through a standard electrical knockout. They are also made from stainless steel to hold up in rain, snow, humidity, general outdoor use, and corrosive environments.

You can use our online panel cooler calculator,

or, If you would like us to do the calculation for you, or purchase consultation and we will followup with you.

If you have any questions please email: support@nexflow.com

Nex Flow® Offers 4 Types of UL Listed NEMA Rated Electrical Panel Coolers:

Frigid-X® Cabinet Panel Coolers NEMA Type 12 (IP-54) For Electronic Control Panels for General use in industrial environments where no direct liquid spray is applied to the unit.Frigid-X® Cabinet Panel Coolers NEMA Type 3R (IP-24) For Electronic Control Panels for Outdoor Use.

Frigid-X® Panel Coolers NEMA Type 4-4X (IP-66) For Electronic Control Panels – splash resistant, for use in washdown environments as well as outdoor use. Unique patented design * for secure watertight protection. Frigid-X® Panel Coolers NEMA Type 4-4X-316L (IP-66) The Patented* NEMA TYPE 4-4X-316L (IP 66) Frigid-X® Panel Cooler are constructed of 316L Stainless Steel. Dust, oil-tight,spray resistant and used in environments where there are liquids and for food service and corrosive environments.

* US patent number 8,616,010 / Other countries: Patented or Patent Pending

Note: Always question non-approved units used on electrical enclosures to assure that your panels are not damaged by inferior products.

Nex Flow® offers a High Temperature Warning Sticker free with every Frigid-X® Panel Cooler purchased for the air conditioning of electrical and electronic control panels. High temperature inside a control panel can be damaging to internal equipment and lead to unplanned shutdown of factory operations. The label provides for an effective warning with a color change indicator to ORANGE and a danger warning with a color change indicator to RED. Color change is reversible so when the temperature problem is corrected, the label can continue to be used indefinitely. While it is a qualitative measurement only, it provides an ideal cautionary monitoring of possible temperature problems within a control panel.

- Advantages

-

Features / Advantages

- Low in cost

- Compact

- No CFCs

- Fast installation

- Stabilize enclosure temperature and humidity

- Virtually maintenance free (No Moving Parts)

- Mounts in a standard electrical knockout

- Stops heat damage and nuisance tripping

- Eliminates fans and filters

- Prevents dirt contamination by keeping enclosure at positive pressure

- Units applicable to all environments including high temperature to 200ºF

- Videos

-

Videos

How Cabinet Panel Coolers Work

Overheating electrical and electronic control panels cause plant shutdowns and costly maintenance issues if not addressed. In many cases regular air conditioning is adequate to address cooling. But some factory environments are better suited to vortex tube operated systems such as the Frigid-XTM Panel Cooler. If you find that your air conditioners are breaking down often because of a nasty factory environment or high vibration causing damage or frequent service and recharging, or if filters require frequent change (and disposal which is an extra cost) then these cooling systems are economical to use.

Compressed air enters at point (A) into the vortex tube component of the panel cooler. The vortex tube splits the compressed air into a hot (B) and cold (C) stream of air. The hot air from the vortex tube is vented to the atmosphere at point (D) after being muffled to reduce noise. Hot air is displaced from inside the cabinet enclosure and exhausted through point (E) via a built in venting system. Cold air enters into the panel at point (F) and distributed via the cold distribution hose (G). Holes (H) are punched into the hose kit to deliver the cold air inside the panel cooler where cooling is required the most. A muffler (I) at the end of the hose further reduces the noise level of the cooled air.

The Frigid-X® Panel Coolers are all RUL tested and approved with three NEMA ratings with equivalent IP rating for other countries – NEMA 12 (IP 54) versions for most control panels, NEMA 3R (IP 24) for outside use, and NEMA 4-4X (IP 66) for corrosive atmospheres. Material is normally 304 stainless bit 316L stainless steel versions also available if required.

Normally Panel Coolers are mounted on the top of control cabinets but if there is no room, side mount systems are available. A Thermostat and Solenoid valve package or Electronic Control System will turn the Panel Cooler on or off as required saving compressed air. In very dirty environments, where a small amount of compressed flow is desired in the enclosure for purging (to keep out a dirty environment) and optional ByPass System is available. - Dimensions

-

Dimensions

- Selection

-

Selection

Cabinet enclosure coolers come with a 5 micron filter with an automatic drain (except for the 316L stainless steel units) for the compressed air supply to insure clean, dry air and an air distribution kit to circulate the cold air inside the enclosure for even cooling.

Cabinet enclosure coolers come with a 5 micron filter with an automatic drain (except for the 316L stainless steel units) for the compressed air supply to insure clean, dry air and an air distribution kit to circulate the cold air inside the enclosure for even cooling.Cabinet enclosure coolers are available with or without thermostat control.

When constant cooling and a constant positive purge is required we recommend the continuous operating version without the thermostat and solenoid valve. The cooling effect can be controlled by adding a regulator in line to reduce pressure for reduced cooling when it is not required and to conserve energy.

Systems utilizing a thermostat and solenoid valve saves air by activating the air conditioner only when the internal temperature reaches a critical level. The adjustable thermostat is factory set at 95°F but can be readjusted on site.

Thermostat and solenoid valve systems are recommended where the heat load can fluctuate (such as for frequency drives) and where a continual purge is not required. The thermostat and solenoid “package” can also be added at a later date to a continuous system. An Electronic Thermostat System is also available replacing the thermostat and solenoid valve with a control box to “set” the temperature (ELC System).

If mounting cannot be on the top of the control panel an optional side mount is available (except or the 316L stainless units). Panel Coolers must be mounted vertical either at the top or at the side using the side mount.

You can use our online panel cooler calculator,

or, If you would like us to do the calculation for you, or purchase consultation and we will followup with you.

If you have any questions please email: support@nexflow.com

Contact Nex Flow® for assistance in sizing cabinet enclosure cooler – Frigid-X® series. See Below for Sizing Specifications

MODEL NO. VERSION BTU/Hr. cooling*(WATTS) dBA at 80 PSIG (5.5 bar) 61004A NEMA Type 12 (IP-54) Continuous Operation 290 (85) 64 61008A NEMA Type 12 (IP-54) Continuous Operation 580 (170) 66 61015A NEMA Type 12 (IP-54) Continuous Operation 1100 (322) 72 61025A NEMA Type 12 (IP-54) Continuous Operation 1800 (527) 73 61030A NEMA Type 12 (IP-54) Continuous Operation 2100 (615) 74 61040A NEMA Type 12 (IP-54) Continuous Operation 2900 (849) 76 63004A NEMA Type 12 (IP-54) Continuous Operation 290 (85) 64 63008A NEMA Type 12 (IP-54) on-off control 580 (170) 66 63015A NEMA Type 12 (IP-54) on-off control 1100 (322) 72 63025A NEMA Type 12 (IP-54) on-off control 1800 (527) 73 63030A NEMA Type 12 (IP-54) on-off control 2100 (615) 74 63040A NEMA Type 12 (IP-54) on-off control 2900 (849) 76 61004R NEMA Type 3R (IP-24) Continuous Operation 290 (85) 64 61008R NEMA Type 3R (IP-24) Continuous Operation 580 (170) 66 61015R NEMA Type 3R (IP-24) Continuous Operation 1100 (322) 72 61025R NEMA Type 3R (IP-24) Continuous Operation 1800 (527) 73 61030R NEMA Type 3R (IP-24) Continuous Operation 2100 (615) 74 61040R NEMA Type 3R (IP-24) Continuous Operation 2900 (849) 76 63004R NEMA Type 3R (IP-24) on-off control 290 (85) 64 63008R NEMA Type 3R (IP-24) on-off control 580 (170) 66 63015R NEMA Type 3R (IP-24) on-off control 1100 (322) 72 63025R NEMA Type 3R (IP-24) on-off control 21800 (527) 73 63030R NEMA Type 3R (IP-24) on-off control 2100 (615) 74 63040R NEMA Type 3R (IP-24) on-off control 2900 (849) 76 61104X NEMA Type 4-4X (IP-66) Continuous Operation 290 (85) 64 61108X NEMA Type 4-4X (IP-66) Continuous Operation 580 (170) 66 61115X NEMA Type 4-4X (IP-66) Continuous Operation 1100 (322) 72 61125X NEMA Type 4-4X (IP-66) Continuous Operation 1800 (527) 73 61130X NEMA Type 4-4X (IP-66) Continuous Operation 2100 (615) 74 61140X NEMA Type 4-4X (IP-66) Continuous Operation 2900 (849) 76 63104X NEMA type 4-4X (IP-66) on-off control 290 (85) 64 63108X NEMA Type 4-4X (IP-66) on-off control 580 (170) 66 63115X NEMA Type 4-4X (IP-66) on-off control 1100 (322) 72 63125X NEMA Type 4-4X (IP-66) on-off control 1800 (527) 73 63130X NEMA Type 4-4X (IP-66) on-off control 2100 (615) 74 63140X NEMA Type 4-4X (IP-66) on-off control 2900 (849) 76 60115X-316L 316 L Stainless Steel NEMA Type 4-4X (IP-66) on-off control (customer supplies own filter)** 1100 (322) 72 60125X-316L 316 L Stainless Steel NEMA Type 4-4X (IP-66) on-off control (customer supplies own filter)** 21800 (527) 73 60130X-316L 316 L Stainless Steel NEMA Type 4-4X (IP-66) on-off control (customer supplies own filter)** 2100 (615) 74 60140X-316L 316 L Stainless Steel NEMA Type 4-4X (IP-66) on-off control (customer supplies own filter)** 2900 (849) 76 ** In 316 environments customers will normally have special filtration systems already in place.

*Cooling effect based on 95°F temperature inside cabinet, 100 PSIG (6.9 BAR) compressor inlet pressure, and 70ºF (21ºC) inlet temperature.

BTU/hr. figures rounded to nearest 100 BTU/hr (1 WATT).

All Continuous Operation models include the cooling unit, filter with auto drain and cold air distribution kit.

All On-Off control units include the cooling unit, filter with auto drain, cold air distribution kit, solenoid valve and thermostat.

- Calculating Heat Load

-

Calculating Head Load

You can use our online panel cooler calculator,

or, If you would like us to do the calculation for you, or purchase consultation and we will followup with you.

If you have any questions please email: support@nexflow.com

Total heat load consists of the heat transfer from outside your panel and from the heat dissipated inside the control unit.

Useful terms and conversions:

1 BTU/hr = 0.293 watts

1 BTU/hr – 0.000393 horsepower

1 Watt = 3.415 BTU/hr

1 horsepower = 2544 BTU/hr

1 Watt = 0.00134 horsepower

1 Square Foot = 0.0929 square meters

1 Square Meter = 10.76 square footTypical fan capacity:

4″ fan: 100 CFM (2832 LPM)

6″ fan: 220 CFM (6230 LPM)

8″ fan: 340 CFM (9628 LPM)

10″ fan 550 CFM (15574 LPM)BTU/hr. cooling effect from fan 1.08 x (temp. inside panel in °F – temp. outside panel in degrees F) x CFM.

Watts cooling effect from fan: 0.20 x (temp. inside panel in °C – temp. outside panel in degrees C) x LPM.

Calculating BTU/hr. or Watts:

- Determine the heat generated inside the enclosure. Approximations may be necessary. For example, if you know the power generated inside the unit, assume 10% of the energy is dissipated as heat.

- For heat transfer from the outside, calculate the area exposed to the atmosphere except for the top of the control panel.

- Choose the internal temperature you wish to have, and choose the temperature difference between it and the maximum external temperature expected.

- From the conversion table that follows, determine the BTU/hr. per square foot (or watts per square meter) for the temperature difference.

- Multiply the panel surface area times the BTU/hr. per square foot (or watts per square meter) to get the external heat transfer in BTU/hr or in watts.

- Sum the internal and external heat loads calculated.

- If you do not know the power used in the enclosure but you can measure temperatures, then measure the temperature difference between the outside at current temperature, and the present internal cabinet temperature.

- Note size and number of any external fans. Provide this information to Nex Flow® to assist in sizing the appropriate cooling system.

Temperature Difference in °F BTU/hr./sq. ft. Temperature Difference in °C Watts/sq.m 5 1.5 3 5.2 10 3.3 6 11.3 15 5.1 9 17.6 20 7.1 12 24.4 25 9.1 15 31.4 30 11.3 18 39.5 35 13.8 21 47.7 40 16.2 24 55.6 Example:

The control panel cooler has two frequency drives totaling 10 horsepower and one module rated at 100 watts. The maximum outside temperature expected is 105°F or 40.5°C. The area of the control panel cooler exposed sides, except for the top is 42 square feet or 3.9 square meters. We want the internal temperature to be 95° or 35°C.

Total internal power is 10 hp x 746 watts/hp – 7460 plus 100 watts = 7560 watts.

Assume 10% forms heat = an internal heat load of 756 watts.Or

Total internal power is 10 hp x 2544 BTU/hp = 25440 BTU/hr plus 100 watts x 3.415 BTU/hr/watt = 25782 BTU/hr.

Assume 10% forms heat = an internal heat load of 2578 BTU/hr.

External heat load: The temperature difference between the desired temperature and the outside is 10°F or 5.5°C. Using the conversions (and interpolating where necessary) we multiply the area by the conversion factor:

42 sq. ft x 3.3 – 139 BTU/hr or 3.9 sq. m x 10.3 = 40 watts

Total Heat Load: 756 + 40 – 796 watts or 2578 + 139 – 2717 BTU/hr.

You would use a Model 61040 for constant operation or a Model 63040 for one-off control. (Rated at 2900 BTU/hr or 849 watts).

- Pricing

-

Panel Coolers PART NO. DESCRIPTION PRICE US DOLLARS 60002A NEMA 12 FRIGID-X Enclosure Cooler Only $350.00 60004A NEMA 12 FRIGID-X Enclosure Cooler Only $350.00 60008A NEMA 12 FRIGID-X Enclosure Cooler Only $350.00 60010A NEMA 12 FRIGID-X Enclosure Cooler Only $430.00 60015A NEMA 12 FRIGID-X Enclosure Cooler Only $430.00 60025A NEMA 12 FRIGID-X Enclosure Cooler Only $430.00 60030A NEMA 12 FRIGID-X Enclosure Cooler Only $430.00 60040A NEMA 12 FRIGID-X Enclosure Cooler Only $430.00 60002R NEMA 3R FRIGID-X Enclosure Cooler Only $365.00 60004R NEMA 3R FRIGID-X Enclosure Cooler Only $365.00 60008R NEMA 3R FRIGID-X Enclosure Cooler Only $365.00 60010R NEMA 3R FRIGID-X Enclosure Cooler Only $445.00 60015R NEMA 3R FRIGID-X Enclosure Cooler Only $445.00 60025R NEMA 3R FRIGID-X Enclosure Cooler Only $445.00 60030R NEMA 3R FRIGID-X Enclosure Cooler Only $445.00 60040R NEMA 3R FRIGID-X Enclosure Cooler Only $445.00 60102X NEMA 4-4X FRIGID-X Enclosure Cooler Only $471.00 60104X NEMA 4-4X FRIGID-X Enclosure Cooler Only $471.00 60108X NEMA 4-4X FRIGID-X Enclosure Cooler Only $471.00 60110X NEMA 4-4X FRIGID-X Enclosure Cooler Only $496.00 60115X NEMA 4-4X FRIGID-X Enclosure Cooler Only $496.00 60125X NEMA 4-4X FRIGID-X Enclosure Cooler Only $496.00 60130X NEMA 4-4X FRIGID-X Enclosure Cooler Only $496.00 60140X NEMA 4-4X FRIGID-X Enclosure Cooler Only $496.00 60102X-316L NEMA 4-4X FRIGID-X 316L Stainless Enclosure Cooler Only $942.00 60104X-316L NEMA 4-4X FRIGID-X 316L Stainless Enclosure Cooler Only $942.00 60108X-316L NEMA 4-4X FRIGID-X 316L Stainless Enclosure Cooler Only $942.00 60110X-316L NEMA 4-4X FRIGID-X 316L Stainless Enclosure Cooler Only $992.00 60115X-316L NEMA 4-4X FRIGID-X 316L Stainless Enclosure Cooler Only $992.00 60125X-316L NEMA 4-4X FRIGID-X 316L Stainless Enclosure Cooler Only $992.00 60130X-316L NEMA 4-4X FRIGID-X 316L Stainless Enclosure Cooler Only $992.00 60140X-316L NEMA 4-4X FRIGID-X 316L Stainless Enclosure Cooler Only $992.00 60002AD NEMA 12 FRIGID-X Enclosure Cooler Only + hose kit (69005) $385.00 60004AD NEMA 12 FRIGID-X Enclosure Cooler Only + hose kit (69005) $385.00 60008AD NEMA 12 FRIGID-X Enclosure Cooler Only + hose kit (69005) $385.00 60010AD NEMA 12 FRIGID-X Enclosure Cooler Only + hose kit (69004) $472.00 60015AD NEMA 12 FRIGID-X Enclosure Cooler Only + hose kit (69004) $472.00 60025AD NEMA 12 FRIGID-X Enclosure Cooler Only + hose kit (69004) $472.00 60030AD NEMA 12 FRIGID-X Enclosure Cooler Only + hose kit (69004) $472.00 60040AD NEMA 12 FRIGID-X Enclosure Cooler Only + hose kit (69004) $472.00 60002RD NEMA 3R FRIGID-X Enclosure Cooler Only + hose kit (69005) $400.00 60004RD NEMA 3R FRIGID-X Enclosure Cooler Only + hose kit (69005) $400.00 60008RD NEMA 3R FRIGID-X Enclosure Cooler Only + hose kit (69005) $400.00 60010RD NEMA 3R FRIGID-X Enclosure Cooler Only + hose kit (69004) $487.00 60015RD NEMA 3R FRIGID-X Enclosure Cooler Only + hose kit (69004) $487.00 60025RD NEMA 3R FRIGID-X Enclosure Cooler Only + hose kit (69004) $487.00 60030RD NEMA 3R FRIGID-X Enclosure Cooler Only + hose kit (69004) $487.00 60040RD NEMA 3R FRIGID-X Enclosure Cooler Only + hose kit (69004) $487.00 60102XD NEMA 4-4X FRIGID-X Enclosure Cooler Only + hose kit (69005) $506.00 60104XD NEMA 4-4X FRIGID-X Enclosure Cooler Only + hose kit (69005) $506.00 60108XD NEMA 4-4X FRIGID-X Enclosure Cooler Only + hose kit (69005) $506.00 60110XD NEMA 4-4X FRIGID-X Enclosure Cooler Only + hose kit (69004) $538.00 60115XD NEMA 4-4X FRIGID-X Enclosure Cooler Only + hose kit (69004) $538.00 60125XD NEMA 4-4X FRIGID-X Enclosure Cooler Only + hose kit (69004) $538.00 60130XD NEMA 4-4X FRIGID-X Enclosure Cooler Only + hose kit (69004) $538.00 60140XD NEMA 4-4X FRIGID-X Enclosure Cooler Only + hose kit (69004) $538.00 60102X-316L-D NEMA 4-4X FRIGID-X 316L Stainless Cooler + hose kit (69005) $977.00 60102X-316L-D NEMA 4-4X FRIGID-X 316L Stainless Cooler + hose kit (69005) $977.00 60102X-316L-D NEMA 4-4X FRIGID-X 316L Stainless Cooler + hose kit (69005) $977.00 60110X-316L-D NEMA 4-4X FRIGID-X 316L Stainless Cooler + hose kit (69004) $1,034.00 60115X-316L-D NEMA 4-4X FRIGID-X 316L Stainless Cooler + hose kit (69004) $1,034.00 60125X-316L-D NEMA 4-4X FRIGID-X 316L Stainless Cooler + hose kit (69004) $1,034.00 60130X-316L-D NEMA 4-4X FRIGID-X 316L Stainless Cooler + hose kit (69004) $1,034.00 60140X-316L-D NEMA 4-4X FRIGID-X 316L Stainless Cooler + hose kit (69004) $1,034.00 61002A NEMA 12 FRIGID-X Enclosure Cooler Only + hose kit + filter (90004) – continuous system $484.00 61004A NEMA 12 FRIGID-X Enclosure Cooler Only + hose kit + filter (90004) – continuous system $484.00 61008A NEMA 12 FRIGID-X Enclosure Cooler Only + hose kit + filter (90004) – continuous system $484.00 61010A NEMA 12 FRIGID-X Enclosure Cooler Only + hose kit + filter (90004) – continuous system $597.00 61015A NEMA 12 FRIGID-X Enclosure Cooler Only + hose kit + filter (90004) – continuous system $597.00 61025A NEMA 12 FRIGID-X Enclosure Cooler Only + hose kit + filter (90004) – continuous system $597.00 61030A NEMA 12 FRIGID-X Enclosure Cooler Only + hose kit + filter (90004) – continuous system $597.00 61040A NEMA 12 FRIGID-X Enclosure Cooler Only + hose kit + filter (90004) – continuous system $597.00 61002R NEMA 3R FRIGID-X Enclosure Cooler Only + hose kit + filter (90004) – continuous system $499.00 61004R NEMA 3R FRIGID-X Enclosure Cooler Only + hose kit + filter (90004) – continuous system $499.00 61008R NEMA 3R FRIGID-X Enclosure Cooler Only + hose kit + filter (90004) – continuous system $499.00 61010R NEMA 3R FRIGID-X Enclosure Cooler Only + hose kit + filter (90004) – continuous system $612.00 61015R NEMA 3R FRIGID-X Enclosure Cooler Only + hose kit + filter (90004) – continuous system $612.00 61025R NEMA 3R FRIGID-X Enclosure Cooler Only + hose kit + filter (90004) – continuous system $612.00 61030R NEMA 3R FRIGID-X Enclosure Cooler Only + hose kit + filter (90004) – continuous system $612.00 61040R NEMA 3R FRIGID-X Enclosure Cooler Only + hose kit + filter (90004) – continuous system $612.00 61102X NEMA 4-4X FRIGID-X Enclosure Cooler Only + hose kit + filter (90007) – continuous system $631.00 61104X NEMA 4-4X FRIGID-X Enclosure Cooler Only + hose kit + filter (90007) – continuous system $631.00 61108X NEMA 4-4X FRIGID-X Enclosure Cooler Only + hose kit + filter (90007) – continuous system $631.00 61110X NEMA 4-4X FRIGID-X Enclosure Cooler Only + hose kit + filter (90007) – continuous system $663.00 61115X NEMA 4-4X FRIGID-X Enclosure Cooler Only + hose kit + filter (90007) – continuous system $663.00 61125X NEMA 4-4X FRIGID-X Enclosure Cooler Only + hose kit + filter (90007) – continuous system $663.00 61130X NEMA 4-4X FRIGID-X Enclosure Cooler Only + hose kit + filter (90007) – continuous system $663.00 61140X NEMA 4-4X FRIGID-X Enclosure Cooler Only + hose kit + filter (90007) – continuous system $663.00 63002A NEMA 12 FRIG-X Cl. + hose kit + filter + therm. (90017) & sol.(90020) – on/off control standard thermostat $860.00 63004A NEMA 12 FRIG-X Cl. + hose kit + filter + therm. (90017) & sol.(90020) – on/off control standard thermostat $860.00 63008A NEMA 12 FRIG-X Cl. + hose kit + filter + therm. (90017) & sol.(90020) – on/off control standard thermostat $860.00 63010A NEMA 12 FRIG-X Cl. + hose kit + filter + therm. (90017) & sol.(90020) – on/off control standard thermostat $973.00 63015A NEMA 12 FRIG-X Cl. + hose kit + filter + therm. (90017) & sol.(90020) – on/off control standard thermostat $973.00 63025A NEMA 12 FRIG-X Cl. + hose kit + filter + therm. (90017) & sol.(90020) – on/off control standard thermostat $973.00 63030A NEMA 12 FRIG-X Cl. + hose kit + filter + therm. (90017) & sol.(90020) – on/off control standard thermostat $973.00 63040A NEMA 12 FRIG-X Cl. + hose kit + filter + therm. (90017) & sol.(90020) – on/off control standard thermostat $973.00 63002R NEMA 3R FRIG-X Cl. + hose kit + filter + therm. (90017) & sol.(90020) – on/off control standard thermostat $875.00 63004R NEMA 3R FRIG-X Cl. + hose kit + filter + therm. (90017) & sol.(90020) – on/off control standard thermostat $875.00 63008R NEMA 3R FRIG-X Cl. + hose kit + filter + therm. (90017) & sol.(90020) – on/off control standard thermostat $875.00 63010R NEMA 3R FRIG-X Cl. + hose kit + filter + therm. (90017) & sol.(90020) – on/off control standard thermostat $988.00 63015R NEMA 3R FRIG-X Cl. + hose kit + filter + therm. (90017) & sol.(90020) – on/off control standard thermostat $988.00 63025R NEMA 3R FRIG-X Cl. + hose kit + filter + therm. (90017) & sol.(90020) – on/off control standard thermostat $988.00 63030R NEMA 3R FRIG-X Cl. + hose kit + filter + therm. (90017) & sol.(90020) – on/off control standard thermostat $988.00 63040R NEMA 3R FRIG-X Cl. + hose kit + filter + therm. (90017) & sol.(90020) – on/off control standard thermostat $988.00 63102X NEMA 4-4X FRIG-X Encl. Cl. + hs kit + fr + ther. (90017) & sol.(90018) – on/off control standard thermostat $1,007.00 63104X NEMA 4-4X FRIG-X Encl. Cl. + hs kit + fr + ther. (90017) & sol.(90018) – on/off control standard thermostat $1,007.00 63108X NEMA 4-4X FRIG-X Encl. Cl. + hs kit + fr + ther. (90017) & sol.(90018) – on/off control standard thermostat $1,007.00 63110X NEMA 4-4X FRIG-X Encl. Cl. + hs kit + fr + ther. (90017) & sol.(90018) – on/off control standard thermostat $1,039.00 63115X NEMA 4-4X FRIG-X Encl. Cl. + hs kit + fr + ther. (90017) & sol.(90018) – on/off control standard thermostat $1,039.00 63125X NEMA 4-4X FRIG-X Encl. Cl. + hs kit + fr + ther. (90017) & sol.(90018) – on/off control standard thermostat $1,039.00 63130X NEMA 4-4X FRIG-X Encl. Cl. + hs kit + fr + ther. (90017) & sol.(90018) – on/off control standard thermostat $1,039.00 63140X NEMA 4-4X FRIG-X Encl. Cl. + hs kit + fr + ther. (90017) & sol.(90018) – on/off control standard thermostat $1,039.00 63002A-ELC NEMA 12 FRIG-X Cl. + hose kit + filter + ELECTRONIC CONTROL PACKAGED SYSTEM $1,465.00 63004A-ELC NEMA 12 FRIG-X Cl. + hose kit + filter + ELECTRONIC CONTROL PACKAGED SYSTEM $1,465.00 63008A-ELC NEMA 12 FRIG-X Cl. + hose kit + filter + ELECTRONIC CONTROL PACKAGED SYSTEM $1,465.00 63010A-ELC NEMA 12 FRIG-X Cl. + hose kit + filter + ELECTRONIC CONTROL PACKAGED SYSTEM $1,578.00 63015A-ELC NEMA 12 FRIG-X Cl. + hose kit + filter + ELECTRONIC CONTROL PACKAGED SYSTEM $1,578.00 63025A-ELC NEMA 12 FRIG-X Cl. + hose kit + filter + ELECTRONIC CONTROL PACKAGED SYSTEM $1,578.00 63030A-ELC NEMA 12 FRIG-X Cl. + hose kit + filter + ELECTRONIC CONTROL PACKAGED SYSTEM $1,578.00 63040A-ELC NEMA 12 FRIG-X Cl. + hose kit + filter + ELECTRONIC CONTROL PACKAGED SYSTEM $1,578.00 63002R-ELC NEMA 3RFRIG-X Cl. + hose kit + filter + ELECTRONIC CONTROL PACKAGED SYSTEM $1,480.00 63004R-ELC NEMA 3RFRIG-X Cl. + hose kit + filter + ELECTRONIC CONTROL PACKAGED SYSTEM $1,480.00 63008R-ELC NEMA 3RFRIG-X Cl. + hose kit + filter + ELECTRONIC CONTROL PACKAGED SYSTEM $1,480.00 63010R-ELC NEMA 3RFRIG-X Cl. + hose kit + filter + ELECTRONIC CONTROL PACKAGED SYSTEM $1,593.00 63015R-ELC NEMA 3RFRIG-X Cl. + hose kit + filter + ELECTRONIC CONTROL PACKAGED SYSTEM $1,593.00 63025R-ELC NEMA 3RFRIG-X Cl. + hose kit + filter + ELECTRONIC CONTROL PACKAGED SYSTEM $1,593.00 63030R-ELC NEMA 3RFRIG-X Cl. + hose kit + filter + ELECTRONIC CONTROL PACKAGED SYSTEM $1,593.00 63040R-ELC NEMA 3RFRIG-X Cl. + hose kit + filter + ELECTRONIC CONTROL PACKAGED SYSTEM $1,593.00 63102X-ELC NEMA 4-4X FRIG-X Encl. Cl. + hose kit + filter + ELECTR. CONTROL PACKAGED SYSTEM $1,612.00 63104X-ELC NEMA 4-4X FRIG-X Encl. Cl. + hose kit + filter + ELECTR. CONTROL PACKAGED SYSTEM $1,612.00 63108X-ELC NEMA 4-4X FRIG-X Encl. Cl. + hose kit + filter + ELECTR. CONTROL PACKAGED SYSTEM $1,612.00 63110X-ELC NEMA 4-4X FRIG-X Encl. Cl. + hose kit + filter + ELECTR. CONTROL PACKAGED SYSTEM $1,644.00 63115X-ELC NEMA 4-4X FRIG-X Encl. Cl. + hose kit + filter + ELECTR. CONTROL PACKAGED SYSTEM $1,644.00 63125X-ELC NEMA 4-4X FRIG-X Encl. Cl. + hose kit + filter + ELECTR. CONTROL PACKAGED SYSTEM $1,644.00 63130X-ELC NEMA 4-4X FRIG-X Encl. Cl. + hose kit + filter + ELECTR. CONTROL PACKAGED SYSTEM $1,644.00 63140X-ELC NEMA 4-4X FRIG-X Encl. Cl. + hose kit + filter + ELECTR. CONTROL PACKAGED SYSTEM $1,644.00 More Information or Buy Here Frigid-X™ By-Pass System for Panel cooler PART NO. DESCRIPTION PRICE US DOLLARS 69700 Bypass System to make a constant purge system – One system for each cooler is necessary $250.00 More Information or Buy Here Muffling Kits for Panel Coolers PART NO. DESCRIPTION PRICE US DOLLARS 69501 Cold End Muffler Kit for 10 to 40 SCFM Panel Cooler Units $100.00 69502 Hot End Muffler & Heat Guard Kit for 10 to 40 SCFM Panel Cooler Units $100.00 69503 Cold End Muffler Kit for 2 to 8 SCFM Panel Cooler Units $95.00 69504 Hot End Muffler & Heat Guard Kit for 2 to 8 SCFM Panel Cooler Units $95.00 69505 Hot and Cold End Muffler & Heat Guard Kit for 10 to 40 SCFM Panel Cooler Units $200.00 69506 Hot and Cold End Muffler & Heat Guard Kit for 2 to 8 SCFM Panel Cooler Units $190.00 More Information or Buy Here