WHY NEX FLOW RING BLADE AIR WIPES ARE SO MUCH BETTER THAN COMPETITIVE OLD TECHNOLOGIES AND EVEN OTHER OPTIONS

Older technology compressed air operated air wipes are built from UHMW blocks or similar material. These air wipe or circular air knife usually have a hinge to open and close the block around the extruded material which has some air holes drilled into it. With this style it is often tout that it uses less compressed air for blow off. However, in practice you normally need more than one unit. It may take as many as five units of this style to do the same job as a Nex Flow Ring Blade air wipe, so you actually end up using much less compressed air. In addition to being more effective, the Ring Blade air wipes are typically much less expensive and produce even a lower noise level.

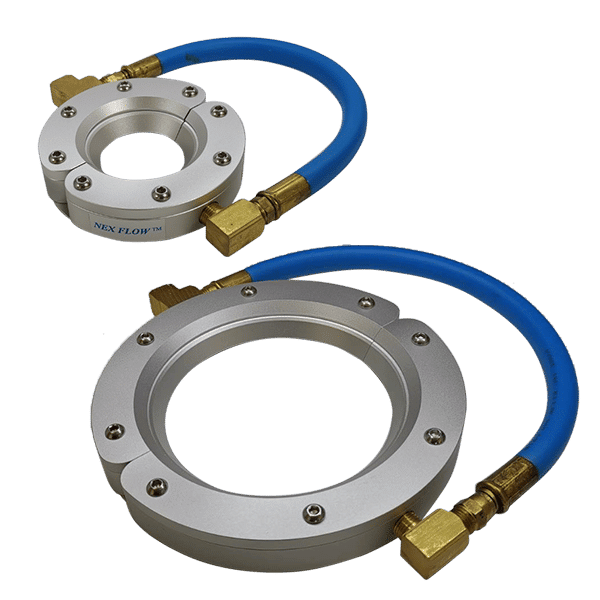

Let’s compare a typical situation. Take two units of a ½” UHMW version which uses 8.3 SCFM each or a total of 16.6 SCFM at 80 PSIG. Units of this design can produce noise levels of 85 dBA. One Nex Flow Model 20000 – ½” Ring Blade air wipe only requires 14 SCFM at 80 PSIG with a noise level of 75 dBA and can easily remove water from an extrusion in a single pass. Only one is required. The question is often asked “how many do you need” and the answer depends on many factors such as the smoothness and surface tension of the liquid on the surface of the material to be removed, speed and the distance from the air wipe to the material surface. The 360 degree uniform “amplified laminar flow” of air removes liquid evenly and quickly.

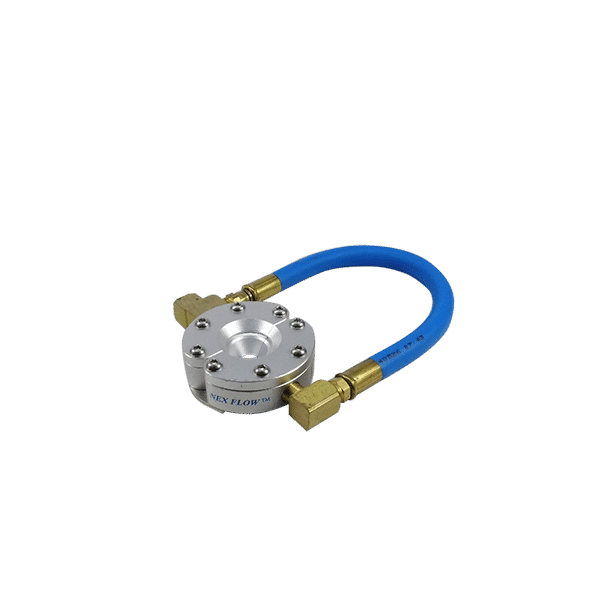

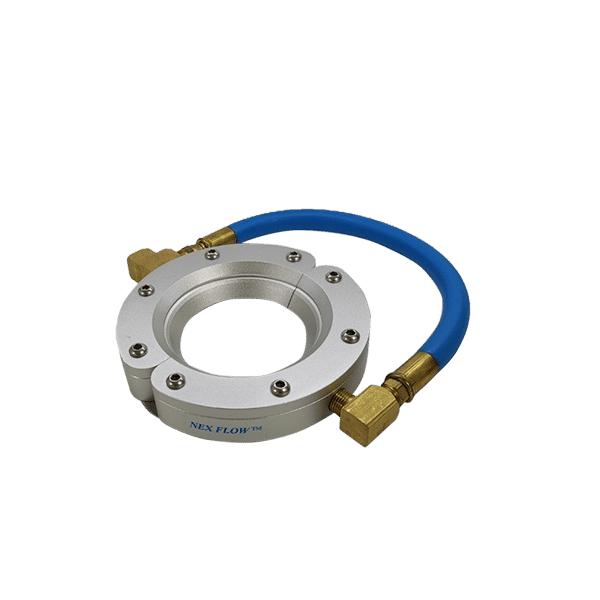

Nex Flow air wipes come in aluminum with rubber hose connecting each half of the mated semi-circular parts, or aluminum with brass fittings and stainless hose for temperatures up to 400 degrees F and in 316L stainless steel with a braided stainless-steel hose and fittings for temperatures up to 800 degrees F and for highly corrosive environments. Nex Flow Ring Blade can reduce noise levels compared to older designs by as much as 10 dBA.

Old technology plastic block air wipes that are used for larger diameter extrusions tend to be longer and take up more space. They can still be loud at over 80 dBA as well. The Nex Flow Ring Blade design is much shorter and compact, even for large diameters and can still reduce noise levels significantly while doing a better job in drying with less number of units and less space for each installation.

Blower operated may offer lower energy consumption, but the same issues can arise in blow off. The biggest complaint from such systems is insufficient drying (just as in the old plastic block design), requiring multiple units, much higher noise levels, and a higher footprint. All this leads to higher capital cost, and increased maintenance which can offset energy savings. When the job really needs to be done, the Nex Flow Ring Blade is an obvious choice.

FEATURED PRODUCTS

The Nex Flow air wipes use a special series of Coanda angles to convert noise and pressure drop high velocity flow. The angles and even the positioning of how the air exists the plenum chamber and goes over the angles can make a difference. One of the factors to consider is something called “blowback”. This is where the air existing the air wipe can actually reverse flow at some point. Some designs similar to the Nex Flow Ring Blade do not seem to take this effect into account but we do. Each Nex Flow unit is designed to avoid this “blowback” effect and perform optimally when drying extruded parts.

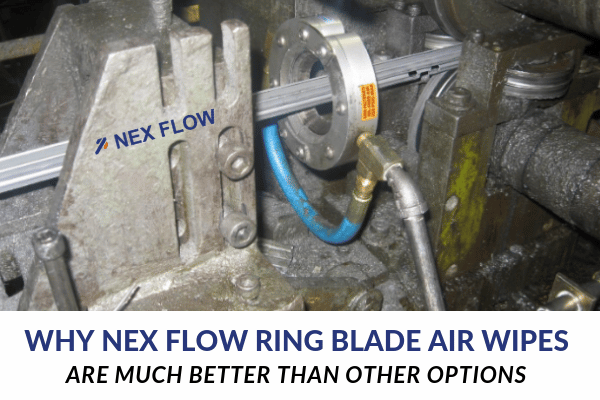

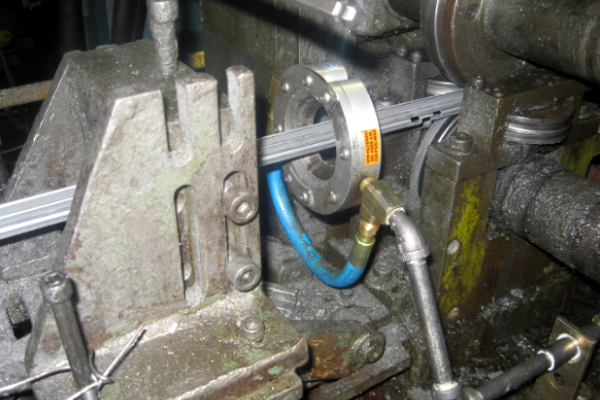

NEX FLOW RING BLADE AIR WIPE – COMPACT, EFFICIENT and QUIET and can clean and dry even complex shapes as this photo shows.

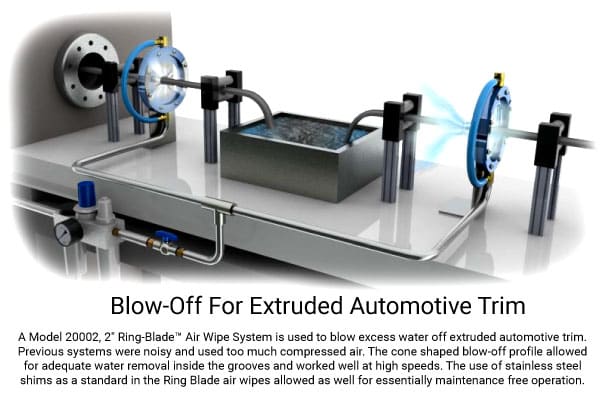

Two other important factors should be considered when comparing designs similar to the Ring Blade: One is that Nex Flow always uses stainless steel shims to maintain the air gap for longer life rather than plastic shims used by competitors. Secondly, all aluminum Ring Blades are anodized (most competitive units are NOT), again for longer life and metal protection. Stainless steel units are not just 303/304 stainless but are higher quality 316L stainless steel making them the best choice for applications like drying medical tube extrusions. All this at generally a much lower cost.

When using Nex Flow Ring Blade air wipes for all sorts of extrusions their design can even address complex shapes such as EPDM profiles like the trim on an automobile. The angled high velocity flow will get into corners and crevices to help dry in many cases, even at high speeds.

So when considering air wipes (air knives arranged in a ring shape), and even when checking existing systems, the things to consider are the number of unit being used (or being considered to use), space or footprint cost, noise levels and actual (or expected) performance.