Why is the Compressed Air Pressure Too Low

As discussed in this video, there are causes and solutions to situations where the compressed air pressure is too low for some factory applications.

All equipment that uses this technology is designed to operate at a certain minimum pressure entering that equipment. If the pressure at the point of entry is too low, the equipment can slow down, not work as well, or cease to operate entirely.

One common mistake is increasing the pressure output of the air compressor. This action usually increases pressure at the entry point of the device but also raises energy consumption needlessly.

Addressing the causes of pressure loss in the transmission of compressed air to the device is better. Several factors can contribute to this issue, as explained in the blog.

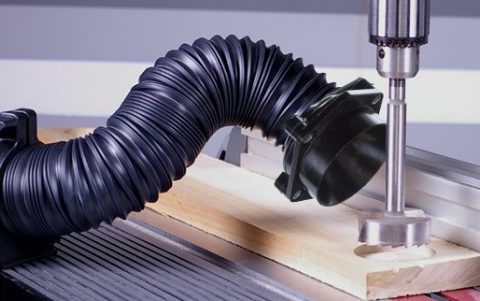

Nex Flow Air Products Corp. manufactures specialized compressed air products for blow-off, cooling, drying, and moving. They also provide accessories like special filtration technology to improve compressed air systems and optimize compressed air use.

Regularly maintain air supply lines. Ensure proper hose diameters and minimize leaks to maintain adequate pressure. These preventive measures help avoid unnecessary energy consumption and ensure efficient equipment operation. Invest in quality air filtration and monitoring systems to detect and resolve pressure issues early, enhancing overall system performance.

Video url : https://youtu.be/rdeoQjsmpWo