Compressed air is a very important tool for food processing and packaging. Food production includes processes like canning, freezing, and dehydration. In this industry – compressed air is used for blow-off applications, cleaning, sorting, cutting, shaping, and conveying food products. It is also used to help form, fill, and seal cartons. The food production industry has approximately 1,300 facilities and employs 112,000 people for processing fruits and vegetables in the United States. The air must be free of contaminants before contact or non-contact with food products. It is the manufacturer’s responsibility to know the composition of the air used to avoid product contamination. The air quality is the measure of these contaminants in the pressurized air. If a component of the air has a harmful effect or makes the condition of the product worse – it is considered a compressed air contaminant. The sources of contaminants in compressed air food processing environments could be physical, chemical, or biological hazards. They include: particles, microorganisms, water, and oil.

Each food processing plant has unique requirements. The goals are to guarantee compliance with standards, levels of food safety, and quality set forth by the FDA and other regulatory entities. This is critical since food products are ingested by humans and animals.

To apply the appropriate regulatory process to for compressed air and food management systems, recognize the following regulatory organizations:

| Regulatory Body | Guideline |

| Safe Quality Food (SQF) Institute | The New SQF Code, Edition 8: Compressed Air Changes |

| Food and Drug Administration (FDA) | Food Safety Modernization Act (FSMA) |

| International Organization for Standardization (ISO)

|

ISO 8573.1:2010 – Contains purity classes for components/contaminants in pressurized air ISO 8573-3:1999 – Describes methods for measuring water vapor, level of uncertainty, and detection range. ISO 8573-2:2007 – Describes Methods A and B for collecting oil aerosol and liquid samples |

| British Retail Consortium (BRC) and British Compressed Air Society (BCAS) | Food and Beverage Grade Compressed Air Best Practice Guideline 102 |

| Global Food Safety Initiative (GFSI) | Benchmark requirements and food safety certification programs for companies to meet high regulatory standards |

| Food Safety System Certification (FSSC) | Recognized by the GFSI

FSSC 22000 certifies and audits food manufacturers using standards from the International Organization for Standardization, ISO 22000 and ISO 22003. |

| International Featured Standards on Food (IFS) | Focuses on Food safety systems during processing and production.

Recognized by the GFSI. |

| Hazard Analysis Critical Control Point (HACCP) | A code of practice for the food and beverage industry. Includes recommendation for compressed air that comes into indirect as well as direct contact with the product.

Goes beyond inspecting finished food product. It finds, corrects, and prevents hazards throughout the production process. |

Sources of Contaminants

The possible sources of contaminants in food processing using compressed air are:

- Ambient air can contain anywhere between 5-25 grams of water, 1-5 micrograms of oil, and 10-100 bacterial parts per cubic meter

- Pipes may contain rust, shed metal, or plastic pipes may shed polymer particles

- Charcoal filters and canisters shed particles

- Sealing tape

- Rubber gasket pieces

- Condensed water, liquid, and oil already present in the system form vapor or aerosol.

- Airborne microbes

- Relative Humidity is a source of moisture in the air

NOTE: ISO 8573.1:2010, British Retail Consortium (BRC) and British Compressed Air Society (BCAS) are specifications that identify potential hazards in the food processing industry.

Impacts of Contaminants

One cubic meter of untreated compressed air contains almost 200 million dirt particles and a lot of water, oil, lead, cadmium and mercury. (Validation of System for Air Quality, https://rastgar-co.com/air-quality/, retrieved November 2, 2018) The impacts of contaminants in a food processing plant are:

- Microbial and bacterial growth on products and equipment

- Corrosive particles landing on sterilized food

- Hazardous consequences to consumer health including the ingestion of hydrocarbons

- Contaminates could accumulate on food products.

- Corrode pipes causing blockages and reduces the life of filters, drains, and machinery in plants.

- Increased energy and money waste.

Understanding Air Quality Factors?

The factors that need to be understood in a food processing environment to improve air quality are:

- Assess the activities and operations that could harm the food product. This is a multistep process:

-

- Identify potential hazards

- Assess the risk of harm

- Assess the controls measures in place for appropriateness

- Prioritize controls and hazards for management

- Assess the need for extra controls by taking preventative steps to remove or reduce the chance of product harm or harm to the customer

- Schedule regular reviews to assess the adequacy of the controls in place

- Determine the extent that the food product is harmed by a potential contaminant

- Determine the likelihood of contamination.

- Understand the impact of air quality on the work zone, workers, and the product or service manufactured.

- Review Direct Product Contact, Indirect Product Contact, USP, and ISO 8573 air standards.

- Understand your requirements for safe food production.

- Engage the production engineers who are most familiar with air quality requirements. They are the resource to determine what needs to be removed from the air and which filter to use for the correct solution. The production engineer would also know the dampness of the air required: moist or dry.

- Determine the amount of moisture required in the air.

- Be aware that pressure reducers and valves can also discharge particles.

- Determine the type of pipes used in the plant

Solutions

The solution depends if the compressed air is in contact with the food product or not.

Contact Application Solutions

Contact application is when the air is used for moving, packaging and transportation of food production. The pressurized air in direct contact with the product needs to be purified to a higher standard than for non-contact applications usually to the -40 oF (-40 oC) dew point, with oil free air and very fine filtration to keep out particulate. Methods to achieve this include:

- Absorption-type compressed air dryers located in the compressor room (centralized air treatment).

- Point-of-use air dryers may be of either desiccant (adsorption) or membrane-type technology.

- Coalescing filters remove solid particulates and total oil (aerosol + vapor).

- Activated carbon filters remove oil vapors.

- De-centralized filtration may be needed in addition to the centralized filtration system.

Engineered nozzles and air knives are used to blow off on a product or packaging while conserving compressed air use by using the Coandă effect to entrain surrounding air along with the compressed air. These products create high velocity, flow and energy air stream. The applications for these compressed air products include:

- Blow off water after washing a product prior to packaging

- Bottling operations to blow off water, especially under “caps” to avoid subsequent problem in potential corrosion issues

- Blow off excess sugar from muffins prior to oven to avoid burnt product

- Cool a product prior to packaging to increase line speed and shorten conveyor length

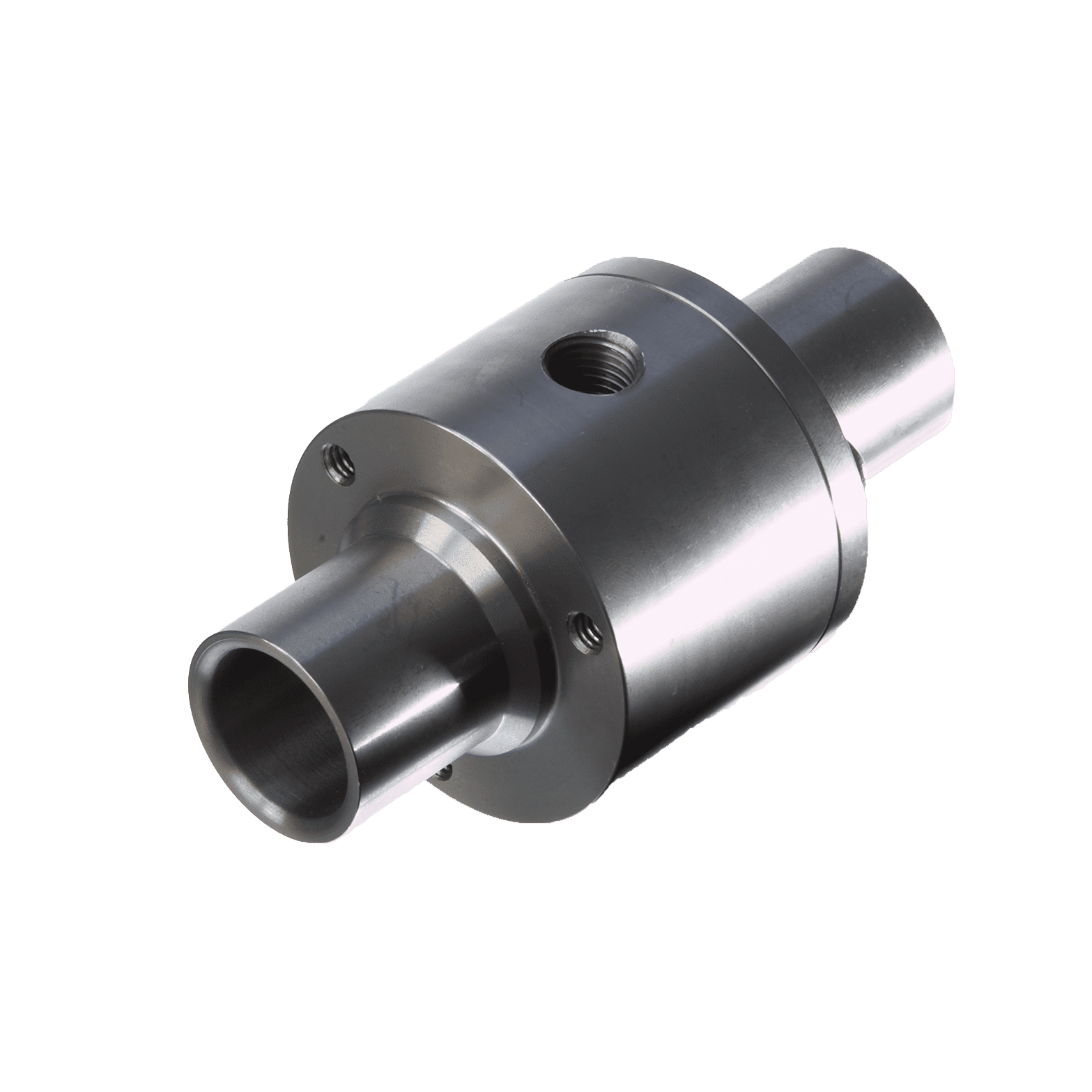

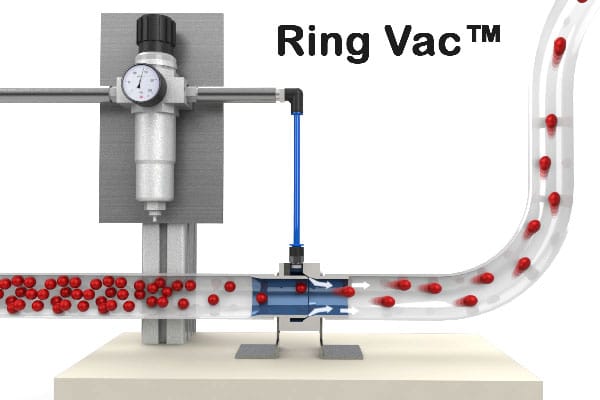

The Nex Flow Ring Vac compressed air operated conveyor (available in stainless steel and anodized aluminum) are ideal use in food industries. These systems are pneumatic conveying units with no moving parts. They are used to convey solid material at high rates and over long distances, such as:

- Convey bottle caps into a hopper for the bottling line. Rather than manually loading caps from smaller boxes, larger containers, which are less costly may be used and then the Ring Vac can be utilized to transfer the caps into the hopper.

- Convey solid food items in food blending operations. One specific application was at a company in SE Asia mixing powders for producing a special food spice. Stainless steel Ring Vacs were welding in line and used to transfer various spices from one place into a mixing tank.

Non-Contact Application Solutions

Non-contact application of compressed air in food production includes expelling air into the atmosphere near food preparation, packaging, storing, or conveying. Blow off is used to clean the packaging prior to filling but if there is a time delay after cleaning, there is a greater risk for contamination including oil, moisture, bacteria, and particulates landing on the product or the container. About 50% of compressed air use in food production facilities will have no contact with food products or packaging, so lower cost methods that treat compressed are acceptable. These solutions include:

- Refrigerated compressed air dryers

- Desiccant air dryers

- Coalescing filters are required to remove solid particles and oil (aerosol and vapor) to the same levels required for contact applications

- Activated carbon filters can be used to remove oil vapors

- Centralized or decentralized filtration depending on the food production facility.

General Solutions for Food Production

This is an incomplete list of possible solutions to meet air quality standards in food production environments:

- Guidelines set out by ISO 8573.1:2010, British Retail Consortium (BRC), and British Compressed Air Society (BCAS) specify that air quality should be tested and verified twice per year or per the manufacturer’s recommendations.

- Monitor equipment for particles, moisture, and oil contaminants

- Install and use oil free compressors and use equipment that is most efficient in your plant

- Use only stainless steel or aluminum pipes, which do not corrode

- Reduce relative humidity in the factory

- Use refrigerated air to remove water, then heat the air to room temperature so that the resulting air is low in humidity and bacterial growth

NOTE: When attached to an oiled pipe – the regulations do not state that the air needs to be tested.

Once the food surface is cleaned, it must be blown with compressed air to ensure no particles are on it.

Refer to ISO 8573 Class 1 or 2 requirements for more information. There is no single solution for all factories when considering the dew point and moisture air management. Dew points of the air at line pressure must be under minus 15 oF (-26 oC) to inhibit growth of microorganisms and fungi.

NOTE: The dew point is the temperature at which air is so saturated with water vapor that when further cooled – the vapor will condense into water droplets (dew).

When using compressed air to blow out bottles prior to inserting liquids for consumption, the most stringent air standards is not necessary because of the expense or the difficulty to regularly test the air quality. In this situation, it is recommended a point of use filter is installed since 1% of the factory uses very high-quality air for specific applications. The rest of the factory does not need high quality air. A point-of-use filter is the cheapest and most efficient solution for greater production.

FEATURED PRODUCTS

Air Quality Testing Strategies

Assessing the food production system’s controls is a customized activity. Keep in mind that compressed air systems are not static. They are dynamic systems because parts breakdown or malfunction, which requires maintenance. Air quality testing is critical to sanitation in the food industry. Although standards are not completely in place, the desire to protect consumers is enough to establish regular air testing. Before starting an air quality testing program, determine the following:

- Schedule routine testing for OSHA, FDA, and Current Good Manufacturing Practices (cGMP) verification and compliance at each facility

- Determine the particulate control level required for your environment: size and count.

- Determine the air testing equipment required with sampling media

- Know the type of oil present in the factory so the type of tube required for testing can be determined.

The testing programs should produce valid, repeatable testing results that reinforce the site’s air quality. Sampling strategies must ensure that air provided to all food production areas has consistent quality. Sampling options include:

- Determine the percentage of sampling points to be tested over time: 25%, 50%, or 100%

- Consider taking three samples: close to the compressor, midway through the process, and far away from purification as possible.

- Sample before and after the filter is changed. Data collected after 3 to 4 filter changes is useful for determining trend analysis.Monitoring of air quality can be done by either testing all critical points of application or randomly testing a representative portion. Although testing all critical points is expensive, it is the most accurate. Contamination can occur at any specific location without affecting other areas in the same plant. Results could later show that the one area not tested was contaminated. Additional testing should be performed after maintenance work is performed on the compressed air system. When maintenance is performed, a sample of air outlets shall be tested to ensure that the quality of the compressed air meets the relevant Purity Classes.

The following is a list of some types of air quality tests:

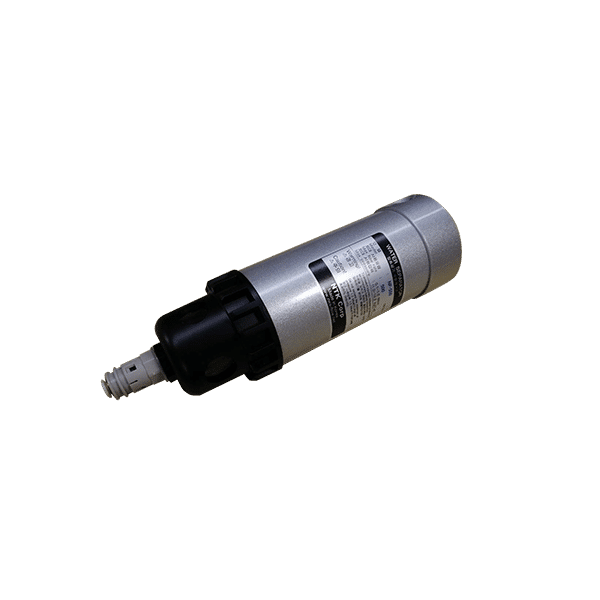

- Laser particle counter

- Filter collection with microscopy

- Solid Particle content by Mass concentration per ISO 8573-8:2004

When collecting samples, ensure that the collection process does not introduce contaminants. Make sure that the sampling equipment is short, straight and made of stainless steel. Any dead ends or bends in the sampling equipment may cause bacterial growth if not cleaned adequately. Straight sampling equipment is important because it will prevent trapping particles before they are sampled.

After the test results are received, ensure that the results fall within the acceptable thresholds by the standards listed in Table 1. Ensure that the controls you have in place are maintained by routine air quality testing. If the tests results show contamination in the plant, then either reassess the limits that were set to see if they were inappropriate for the application or add controls to the existing compressed air equipment. Additional controls could include additional filters or a refrigerant dryer where there are none. Although testing could be expensive, it is the best safeguard against damage or harm.