Alternative to Refrigerant for Industrial Cooling

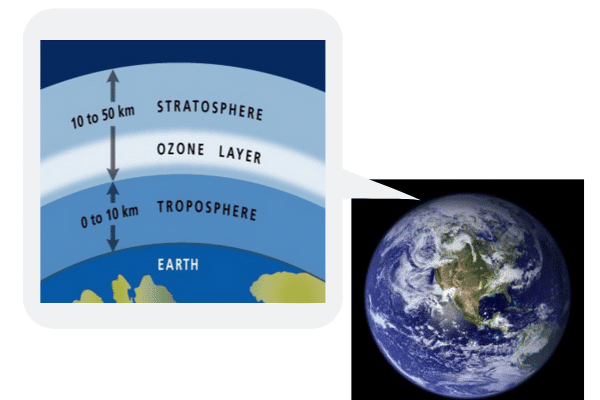

One of the major contributors to the destruction of the ozone layer was chlorofluorocarbons or CFC’s used in air conditioning and refrigeration. Work on alternatives for CFC’s in refrigerants began in the late 1970s after the first warnings of damage to stratospheric ozone were published. This led to the creation of Hydrochlorofluorocarbons (HCFCs) which are less stable in the lower atmosphere. This resulted in the redesign of some equipment as well as replacement of materials which were negatively affected by using the new HCFC’s. The main advantage that HCFCs have over CFC’s is that they are much less stable and more reactive with their additional hydrogen atom(s), meaning they can usually break down in the troposphere before reaching the stratosphere and attacking the ozone. The HCFC’s are actually interim replacements for CFC’s because they still deplete stratospheric ozone, but to a much lesser extent. Ultimately, hydrofluorocarbons (HFCs) will replace HCFCs. Unlike CFCs and HCFCs, HFCs have an ozone depletion potential (ODP) of 0. HFCs were developed in the 1990’s as a replacement to the ozone-damaging chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs). They are now the most dominant cooling agent in new refrigeration, air-conditioning (AC) and heat-pump equipment.

While most modern-day refrigerants are hydrofluorocarbons (HFCs) – they have recently been scrutinized as being a potent greenhouse gas. a problem. HFC’s are widely used in air conditioning systems and their usage is anticipated to rise, with their negative impact on global warming also being predicted to increase.

So now there are plans to phase-out HFCs in air-conditioning systems and new replacement fluids are currently being investigated but options are limited.

HFCs replaced HCFCs in many AC systems, but even now HCFCs are still used in developing countries. Even though the replacement of CFCs and HCFCs by HFCs reduced the risk to the ozone layer, they still possess enough high global-warming-potential (GWP) to warrant research efforts into finding an alternative solution. Refrigerants are the essential working fluids in a vapor compression refrigeration cycle. They absorb heat at low temperatures in the evaporator and release it at high temperatures through a condenser.

There are only a few pure liquids and blends that have the potential to be used as refrigerants to replace HFC’s. Most of the fluids that seemed to have potential at first turned out to be classed as flammable or mildly flammable. Six of these slightly flammable, novel molecules were identified, but present unknown risks, are tetrafluorodioxole, trifluoromethanethiol, trifluoropropyne, difluoromethanethiol, (E)-1,2-difluoroethene (R-1132(E)) and tetrafluoromethaneamine. The flammability of course is a problem.

The other potential is refrigerant blends. 1,1,2,2-Tetrafluoroethane (commercially known as R-134) is a molecule that has been previously considered but was never used commercially. It is now being stipulated that it could be a good candidate for refrigerant blends. Refrigerant blends are currently being developed and tested, and although they don’t perform as efficiently as pure fluids, they minimize the flammability and in some cases, can remove the risk completely. It is a compromise that is being considered and developed, but it does not offer the ‘ideal’ refrigerant that many people are searching for. The problems in finding a new pure refrigerant not only lies in flammability. There are also limitations on size, as the thermodynamics only allows for small molecules, of which there are a finite amount. The unknown risks of some molecules promote the apprehensiveness to use such molecules as years of R&D could yield a useable molecule, so a number of people willing to take a chance on these molecules will be low- even if there is potential. Barring the discovery of a fantastic refrigerant blend, or dealing with the flammability issues, if these are the best choices, what chance do we have of efficiently replacing HFCs?

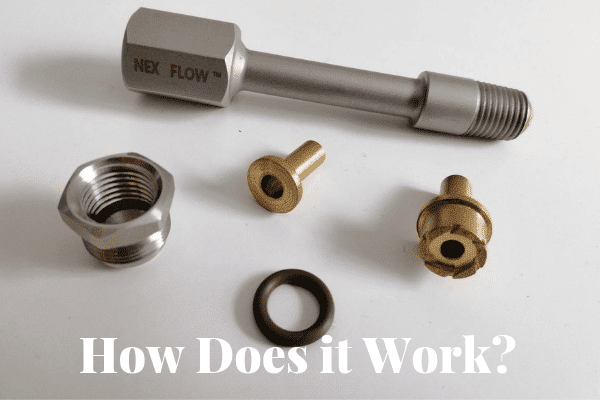

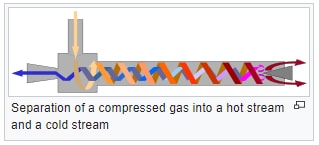

There is however, an alternative that should be considered at least for smaller applications when compressed air is available in industrial applications. That is vortex tube technology. The vortex tube, also known as the Ranque-Hilsch vortex tube, is a mechanical device that takes compressed air and splits the air flow up in such a way that it exits the tube hot at one end and cold at the other. Invented in 1931 by the French physicist Georges J. Ranque, it was commercialized in the 1960’s and still used extensively to day for spot applications (spot cooling) but also to cool electrical and electronic control panels, in particularly very harsh factory environments. One of the issues with vortex tubes is that they operate using compressed air. While great for the environment (they only use the air we breathe!) the high energy cost of compressed air has to be considered. In very dirty factory environments however, this higher energy cost is offset by the higher maintenance costs saved when using traditional air conditioners. In difficult manufacturing environments, standard air conditions have to contend with frequent filter changes, higher levels of breakdown and therefore higher repair costs, shorter life, and more frequent refrigerant replacement due to vibration (which only harms the environment more). Vortex tube technology can actually produce temperatures as low as -40 C or even lower in some cases with virtually zero harm to the environment and require very little maintenance.

Vortex tube technology has not changed much since the 1960’s but is due for efficiency enhancement. If these devices can be improved in efficiency even modestly, they can be used more and more in at least industrial environments. Compressed air is not flammable, does not harm the ozone layer and does not contribute to global warming. If a manufacturing facility is using air conditioners for cooling control panels and even for other cooling applications, they should evaluate their maintenance costs, machine life, the internal labor costs to maintain them, and even the cost of disposing used filters. If the cost is relatively high, they should consider vortex tube technology as an alternative. Vortex tubes have virtually zero maintenance and as long as the compressed air supply is filtered to keep out moisture and dirt, the devices have a lifetime of use with zero maintenance. Apart from cooling control panels and any electrical and electronic cabinets, they find use in all sorts of spot cooling applications because they are so rugged and compact. They are used to cool tooling for example in dry machining. The technology is finding increased usage for machining in the move away from coolant for environmental reasons. CO2 is sometimes used to cool in dry machining but again, you have global warming issues.

Cooling molds with vortex tubes is possible by blowing cold air into the mold cavity. Welds are cooled in metal can production using vortex tubes. Cooling cameras or sensors in factories that are exposed to a hot environment is a major application where vortex tubes are used and provide a great benefit where traditional air conditioning devices would not work well. Basically any open “spot” or any hot enclosure can potentially benefit from vortex tube technology.

There tends to be a stigma against the use of compressed air due to the high energy cost but when considered against environmental cost of alternatives, and against the traditional capital costs, and maintenance costs, it becomes more and more attractive as time goes on. Traditional air conditions will become more costly as alternative refrigerants are adopted for the simple reason that their lower stability means change of internal materials and the cost of the refrigerants themselves. Vortex tube technology will only become more attractive, at least for industrial applications. It does not deplete the ozone, does not contribute to global warming, and uses only the air everyone breathes.