When purchasing a vortex tube device, you must examine the material, construction, adjustability, and noise abatement.

The vortex tube is a unique device that separates compressed air into a hot and cold stream. The concept was discovered in the 1800s but commercialized in the 20th century in the late 1960s. It still took well into the 1980s and 1990s to become more widely known, understood, and applied.

Even today, the concept of the vortex tube has yet to be discovered in many places worldwide. The main advantages of the vortex tube are its ability to “spot cool” with a very small footprint, using only compressed air.

It has found significant use in cooling electrical and electronic control panels, especially in factory environments that are very dirty and humid and where maintenance costs can be high since vortex tubes operate essentially maintenance-free.

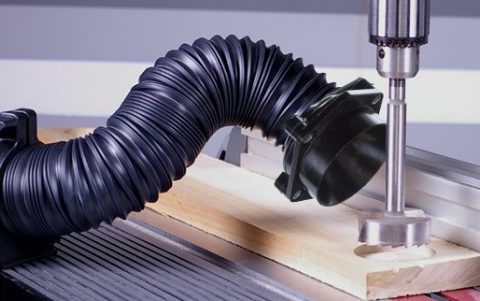

Another growing market is tool cooling in dry machining applications as new materials are developed to replace the need for coolants and their detrimental environmental effects. Nex Flow, in particular, works to improve the efficiency and function of its vortex tube products.

The material of the vortex tube can be anything from aluminum to brass to stainless steel. However, stainless steel has now become the primary material used for the body of the vortex tube by most suppliers of importance.

This is because of the environment where vortex tubes are commonly used. As they are used to cool, it only stands to reason that they are used in hot areas or a hot factory environment. Many of these environments can negatively affect materials such as aluminum and shorten the product’s life span.

The quality of construction is essential. Brazed or welded parts must be done correctly, so they do not break off. Any welds should be clean with no weak spots. Any vortex tube and especially vortex tube packages (including unique sleeves, special attachments, etc.) should be appropriately assembled.

The material of O-rings used and the quality of the material can be very important for some applications. For example, vortex tubes are often packaged as electrical and electronic cabinet enclosure coolers such as Nex Flow Panel Coolers.

Material quality is essential and mandatory for electrical certification in most countries. Nex Flow has these certifications. Quality of construction and assembly is also necessary for optimum performance to optimize its energy use in producing the cold air required.

Adjustability in a vortex tube is achieved by controlling the airflow out of the cold and hot ends. A relationship exists between the temperature drop at the cold end and the flows out the cold end. The smaller the flow out of the cold end, the greater the temperature drop, and vice versa. In some applications, you want to avoid adjustability, but Nex Flow can advise and provide the appropriate setting for the application.

Vortex tubes can be pretty noisy, and adequate muffling at both the hot and cold ends (especially at the cold end) is important. How the mufflers are designed, and the materials used can affect that muffling level. Most companies use plastic as a muffling material. Nex Flow uses a biodegradable natural material that is also fire retardant keeping safety and the environment in mind.

When tested against plastic, usually a foam material, it even proves to be better at a sound reduction.