To choose the perfect blow off product for your manufacturing environment it is important to consider the application, placement in the factory, energy savings, health and safety, and finally material durability.

Application

One of the primary criteria for deciding which blow off product is right for your manufacturing plant is the application desired. This section describes the primary application for the following devices: air amplifier, air jet, air blade air knives, and air guns.

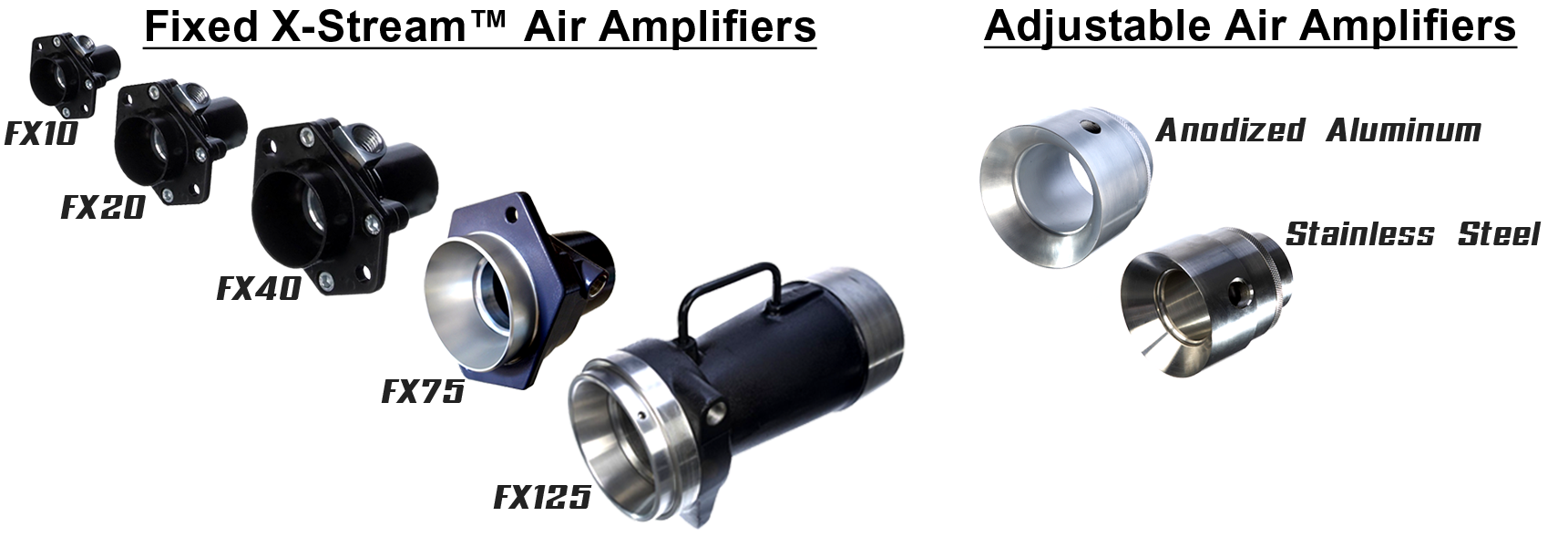

An air amplifier is an air mover that is virtually maintenance free. The primary applications of air amplifiers include cooling, venting exhaust, drying, cleaning, distributing heat in molds or ovens, and collecting dust.

Air Jets entrain large volumes of surrounding air. They are similar to air amplifiers but comes in a smaller size yet are more efficient flow amplifiers than nozzles. These jets cover a larger blow off area than a nozzle and are ideal for part ejection. They are primarily used for cooling, part drying, chip removal, and air assist.

Air BladeTM Air Knives consist of a body with a plenum chamber, cap, and either a machined gap in the body or a shim to maintain an even gap along the length of the air knife. It uses compressed air for industrial blow off and cooling. The laminar sheet of air created by the unit is often used to replace rows of nozzles or jets to reduce energy costs. Air Knife is most commonly used to dry, clean, and cool. Examples of applications include removal of liquid, dust, and excess oils from flat and curved surfaces, conveyor cleaning, blow off before painting surfaces, and scrap removal.

Unlike any of the above units, air guns are not integrated into the factory line but instead are handheld units for blowing off work surfaces and other applications that require a high force or flow application. Safety blow guns are used to blow off metal chips during drilling operations, removing “stuck” material such as tape, gasket material, caulk, adhesive, paint, and labels. With the addition of air, the detached material is blown away during scraping, keeping the area clean.

Location

Although these pressurized air equipment may be ideal for specific applications, they are sometimes interchangeably used based on space availability, desired orientation, and even the factory environment. It is important to keep in mind that these blow off devices must have room for exhaust. Furthermore, if the device is used by a worker, comfortability and ease of maneuver is key.

The shape and size of the unit are important considerations. Air amplifiers and jets are both circular products but jets are smaller in size than amplifiers. Hence the amplifiers can blow off a larger area but with less force than a jet.

Air knives are straight and vary in lengths anywhere between 3” to 36” and can be used as part of an automated conveyor system. Air guns, on the other hand, are typically used at work stations. Extensions and swivels of various lengths and gun tips (i.e. nozzle and air edger) are available, making the safety gun a very flexible handheld unit.

Energy Savings

Depending on the required application, finding the best fitting blow off product allows the equipment to do the same job at less pressure. Energy savings is accomplished by finding blow off products that have the highest force/air consumption ratio. Reducing compressed air use and noise levels translates into an efficient high output air with lower energy use.

Here at Nex FlowTM – we continuously research and design better engineered products for our customers. For instance – our standard air blades have been proven to reduce energy by 30% – 90% as it is designed to produce the most force over the length at the lowest possible input pressure. Taking it a step further – our silent air knives are designed to further reduce energy lost as noise and is 25% more efficient than the standard design.

The best blow off customized product and technical support is obtained by choosing Nex Flow systems. During installation, our highly trained customer technical support advises our customers to install equipment that provides the most accurate blowing angles and direction All Nex Flow compressed air blow off products have a five-year warranty against manufacturer’s defects.

Health and Safety

The most important reason to use Nex Flow® blow off equipment is safety. Air equipment exhaust can be loud. Noise and vibration that are detected by the human ear are classified as sound. “Noise” is the term to describe unwanted sound. Extended exposure to unwanted sound or at high levels can harm workers and can result in profound hearing loss. Hearing loss can also occur as the result of one-time repeated contact to loud sounds or uncomfortable sound pressure over an extended period.

Occupational Safety and Health Administration (OSHA) sets legal limits on noise exposure in the workplace. Guidelines are available that describe permittable duration of exposure for occupational exposure limits (OELs) for various noise levels. These OELs are determined using a weighted average over an 8-hour work day. With unnecessary noise, all workers should be exposed to OSHA’s permissible exposure limit (PEL) of 90 dBA during an 8-hour work day. Note: The OSHA standard uses a 5-dBA exchange rate.

Nex Flow takes noise levels into consideration very seriously because we understand that reducing noise levels from very loud and damaging compressed air equipment is important. Noise levels are much lower when using air nozzles and air jets. The added bonus is that the use of air nozzles and air jets, not only lower noise levels but also lowers energy use.

All Nex Flow blow off products provide noise reduction in factories to ensure the safety of your workers in a factory environment.

Some Air Gun suppliers do not provide energy effective nozzles or are not safe to use. All Nex Flow® air guns are safe to use, have energy efficient nozzles, and meet OSHA guidelines for safety.

Reducing unwanted noise can be achieved through using noise-canceling headphones, mufflers on any exhausting air, or by adding low-cost air amplifying nozzles on blow off devices. To further enhance safety in the manufacturing environment, Nex Flow® monitoring devices can detect sources of noise previously missed or unidentified. Use the Nex Flow Digital Sound Level Meter to accurately monitor noise levels and ensure that high levels of sounds do not exceed OSHA limited standard 29 CFR – 1910.95 (a) which limits an 8-hour exposure of constant noise to 90 dBA. The maximum hold setting will provide the highest noise level and will update continuously if a higher noise level comes into play. If you need to keep a record of sound measurements, a complete data logging system is available.

All of Nex Flow blow off equipment provides noise reduction, meets OSHA safety standards, and are safe to use in any factory environment.

Material Durability

Compressed air operated equipment is generally simple to use, compact, rugged, and portable.

To keep our products durable – we do not use plastic shims to save costs like other manufacturers. Nex FlowTM only uses stainless steel shims to guarantee longer life with still very competitive prices.

It is also important to choose the correct material used to construct the accessories. In a high temperature and corrosive environment, 303/304 Stainless Steel is recommended. The 316L Stainless Steel is recommended for very corrosive or high temperature applications and when the application is food or pharmaceutical grade. Anodized Aluminum is usually suitable for most other application but for oily environment it may be worth choosing the hard-anodized aluminum. Learn more about “Why we do what we do with our materials” here (Link to article).

Nex Flow is the best supplier of blow off products. Our trained customer service and installation technicians can help you identify the criteria that is most important for your blow off application. Educating your workers, while performing regular inspections will enhance their work environment, prevent leaks, and extend the life of your blow off equipment. When choosing the best blow off solution, understanding the benefits of a well-engineered Air Knife, Air Amplifier, Air Jet, and Air Guns to withstand a harsh factory environment with safety in mind is important. Remember Nex Flow is happy to help you and your company to meet all your compressed air needs.