Drying complex parts may require a combination of nozzles, jets, and air knives.

A complex cart can have an odd shape, plus holes and crevices where water can collect. In such cases, it may require several steps in the drying process. Complex parts often have personnel drying manually with a compressed air blowgun. As labor shortages occur, the necessity to automate the drying increases.

The more complex the part, the more steps may be required to clean and dry. Often if the parts were manually dried, they are on a conveyor and an attempt is made to dry the part in the same process. Sometimes this is possible, but sometimes the part may be so complex it needs to be robotically handled, perhaps turned in different directions to dry adequately.

This would be the case if the part were picked up and otherwise handled and dried when it was dried manually.

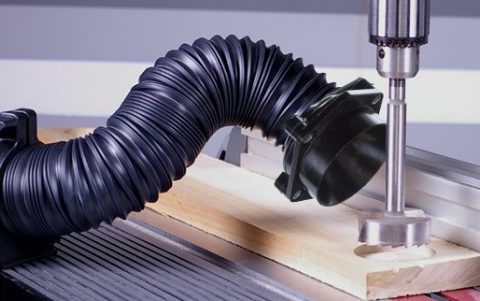

But if it was manually dried before on a conveyor and not handled, it’s usually possible to keep the same process. Small holes and crevices can be blown dry with small nozzles and if they are larger, you can utilize air jets or larger nozzles and even annular air flow amplifiers to splash out the water.

It is essential to ensure that the water does not splash from one hole or crevice into another so the order in which these areas are dried is essential. This can be complicated and may entail an additional drying step or more.

Once the holes and crevice and any other difficult spot holding water are dried, residual water on the part surface is left from splashing, it is sometimes appropriate to sweep the part with a halo of air knives to do a final wipe.

Compressed air drying is efficient because any remaining water droplets will be tiny and evaporate quickly.

Video url : https://youtu.be/gaBFVXZWFuY