Corrosion and Vortex Tube.

When choosing a product, several choices and brands may seem similar. However, significant differences emerge beyond operating specifications.

Often, factories overlook the materials used in products. This becomes crucial in special environments.

In pharmaceutical operations, materials exposed to products or the factory atmosphere need 316 or 316L stainless steel. Fertilizer production facilities may also require 316 stainless steel.

Blow-off products like air nozzles, air amplifiers, and air knives made of aluminum should be anodized. Even a passive manufacturing atmosphere can wear these products quickly.

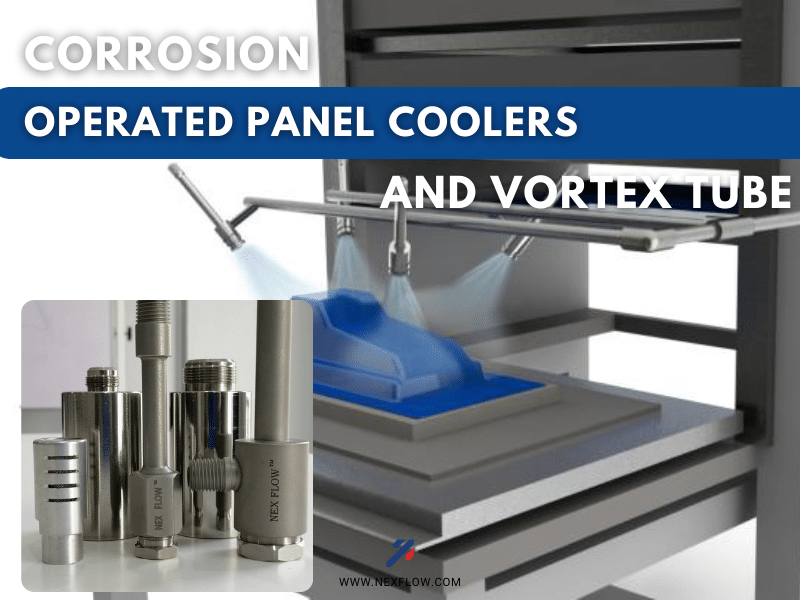

Some vortex-tube-operated panel coolers use stainless steel vortex tubes with non-anodized aluminum covers. This works in dry environments, but wash-downs or high humidity can cause issues.

Dissimilar metals, especially when one is active like aluminum, may face cathodic corrosion when wet. This occurs in wash-down situations.

Corrosion and Vortex Tube

Cathodic corrosion happens when two metals in an electrolyte cause one to corrode. Water, often with detergent, can act as the electrolyte.

In damp conditions, aluminum bodies may corrode and compromise the vortex cooler’s integrity. Corrosion can collect water over time, breeding bacteria, which is disastrous in food production.

Properly designed vortex-tube-operated Cabinet Enclosure Coolers need proper approvals. Nex Flow units meet NEMA Type 12, NEMA Type 3R (for outdoor use), and NEMA Type 4-4X for wash-down applications.

NEMA Type approvals and their IP equivalents (IP 54, IP 14, and IP 66) ensure no moisture enters the enclosure. This includes approved and tested o-rings.

Approvals do not consider water collection or corrosion. Suppliers with engineering expertise recognize the importance of these factors. Knock-off products often ignore these aspects due to ignorance.

Many companies do not highlight corrosion considerations for vortex coolers. This issue is often delegated to maintenance after the fact.

However, considering construction materials, proper approvals, and quality design early on can prevent future headaches.