Compressed Air Blow-Off Force is Too Low

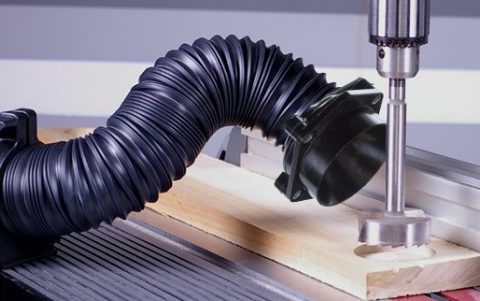

If your blow-off nozzle, air knife, jet, or amplifier force is too low, it could be from several factors that need to be checked.

Compressed air is an energy source that is only sometimes understood. When used for blow-off and the expected force is low, or drops low after some time, it can be consuming as to the cause.

Presuming near zero leaks and adequate compressed air capacity, the primary thing to check when the force seems too low is for pressure drop. You need to check what could be in the compressed air system causing excessive airflow resistance such that the pressure at the point of use is lower than necessary.

By installing a gauge near the point of use and taking a pressure reading while the compressed air-consuming device is operating, this can be confirmed.

One of the things NOT to do is to increase the pressure that the air compressor produces. This not only ends up consuming more energy, it will not solve the problem as explained in the video.

Increasing the size of the engineered air nozzle or the gap in an air amplifier by adding shims to open the gap in an air knife will also generally fail. This is because as you try to draw more air through the compressed air delivery system to the blow-off location, the pressure drop can be aggravated and the force can fall even further.

The source of access pressure drop can be improperly sized fittings, filters, and the air system itself. Replacing fittings and filters can be addressed but if its system design, then the solution can get much more complicated.

Nex Flow Air Products Corp. manufactures compressed air blow-off products and can assist you with blow off applications and issues.

Video url : https://youtu.be/jTnBQa7rzVg