When a compressed air flow amplifier gets dirty, there is no need to remove the units from the line.

Nex Flow compressed air-operated Air Amplifiers are annular flow amplifiers often called “air movers.” They utilize the Coanda effect which operates by taking the energy normally lost as pressure drop and noise and then converting that energy into functional high kinetic energy flow.

This output energy is used for cleaning, drying, and even effectively and efficiently cooling manufactured parts. These assemblies are rugged, with long life, and essentially no maintenance as long as the compressed air supply is kept clean and dry with good drying and filtration.

The reality, however, is that a compressed air system, for whatever reason, is sometimes lacking this clean and dry air at the point where the Air Amplifiers are installed. The issue of dry and clean compressed air may or may not be endemic to the entire compressed air system and may only be an issue where the units are installed.

This is why Nex Flow always recommends point-of-use filtration and even point-of-use compressed air driers (all of which are offered as an option) to ensure that the compressed air supply entering the devices is adequately clean and dry,

Regardless of why there may be a cleanliness problem, should cleanliness issues occur, it is always recommended that it be investigated and corrected after any cleaning to avoid the necessity of cleaning in the future.

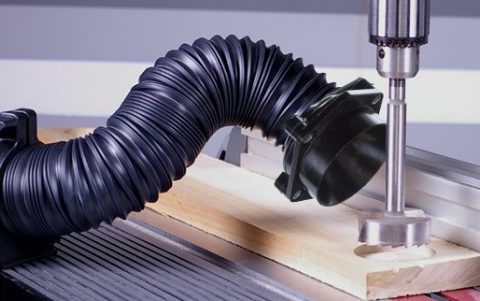

Even with a clean system, there may still be some dirt buildup in the Air Amplifiers, although hopefully an infrequent occurrence. For a minor buildup, this video shows an easy way to remove this particulate but simply loosening the bolts that hold the body and cap together of the Air Amplifier while the compressed air is still flowing and letting the air blow out any deposit. Then just re-tighten.

For any questions on the use of compressed air for blowing, drying, cleaning, moving, or cooling “as Les”