Choosing the best Spot Cooler

What are Spot coolers and their Importance?

Spot coolers are self-contained air conditioning systems that have all the components of larger air conditioning systems but are compact and easy to move. Spot cooling for industrial applications are used short term to cool a small area on a part or in an enclosure – such as a cabinet. Spot coolers are ideal for cooling electronics, computer server rooms, and humans in small confined work environments. They are often praised for their portability, ease of use, and installation.

Fans cannot cool below ambient temperature because they cool by moving air and cool a wider area. Compressed air amplifiers cool better than fans because of the higher velocity but they also do not cool below ambient temperatures. Air amplifiers also cool a wider area. This blog discusses the three most popular ways to cool below ambient temperature, namely Vortex Tubes, thermoelectric, and cryogenic gas (CO2 and Nitrogen Gas) cooling systems.

It is important that the spot cooling system chosen is reliable because sudden or frequent break downs can cause costly equipment damage, repair, or replacement. Keeping humans cool in a small work area is important as well for health and safety concerns. All Spot coolers come with accessories that allow you to direct the cooled air where it is needed most. Any condensation that results from the cooling process is drained through a hose or bucket.

Vortex Tube Cooling System

Vortex Tube Cooling systems are powered by compressed air. The vortex action separates the compressed air into extremely cold and hot streams. The cylindrical form causes the compressed air to rotate at a high speed (reaching 1 million rpm). A small portion of the air exits through a needle valve as hot exhaust. The remaining air is forced through the center of the incoming air stream at a slower speed. The action of the slower moving air dissipates any remaining heat into the faster moving air. The super-cooled air flows through the center of the generator and exits the cold air exhaust. Depending on the temperature and pressure of the incoming compressed air, it is possible to achieve cold end temperatures as low as – 40 and even – 50 degrees F. The hot air (end) can be up to 260° F (127° C). The Vortex cooling system, or cold end of the Vortex Tube, is often used for “spot cooling” of cabinets, such as control panels and industrial cameras.

Vortex Tubes normally come with the “hot end” adjustable to control the flow and temperature out the cold end. The more flow out the hot side, the lower the temperature out the cold side. The cooling effect (BTU/hour) is determined by both flow and temperature drop. Therefore, for cooling applications, the cold end should be between 60% – 80%. If the cold temperature is most important, then the flow out the cold end should be under 50%.

Choosing the best Spot Cooler

Factors in selection:

Vortex Tube cooling systems that use compressed air is considered where conventional enclosure cooling by air conditioners or heat exchangers is not possible. Ideally, Vortex Tube cooling systems are used to cool small to medium size enclosures, nonmetallic enclosures, and areas where the size of cooling devices is restricted.

For optimum cooling results when using a Vortex Tube cooling system, the following items are required when installing:

- Clean, dry, oil-free compressed air

- 80 to 100 PSIG / 70 degrees F or below. Lower pressures and higher temperatures will reduce BTU/H ratings.

- A 5-micron water and particulate removal

- A 5-micron oil removal filter when oil is present

- Thermostats or temperature indicator sticker

- Valve (optional)

- Muffler go minimize exhaust noise

Advantages:

The Vortex Tube cooling system has many advantages. The small, portable, light weight, and compact system creates extremely cold air without refrigerants, included CFCs or HCFCs. It is exceptionally reliable since there are no moving parts and virtually maintenance free. It uses minimal electricity (only for the compressor). Vortex Tube cooling systems are useful in harsh and high temperature environments. Customers can expect a long life from Vortex Tubes because Nex Flow uses only Stainless-Steel with a brass generator. Compressed air is not the only gas that can be used to produce cold air, Nitrogen and other natural gases that can be compressed can be used as well.

Applications:

Vortex Tube cooling systems can be used to cool:

- electronic and electrical control instruments

- machine operations/tooling

- CCTV cameras

- Set hot melt adhesives

- soldered parts

- gas samples

- heat seals

- environmental chambers

- workers wearing protective gear

- data centers

- plastic machined parts and molded plastics

- Electronic components

It is understood that cold and hot gas (bi-product) is generated when using a Vortex Tube cooling system.

Choosing the best Spot Cooler

Thermoelectric Coolers (Peltier Effect)

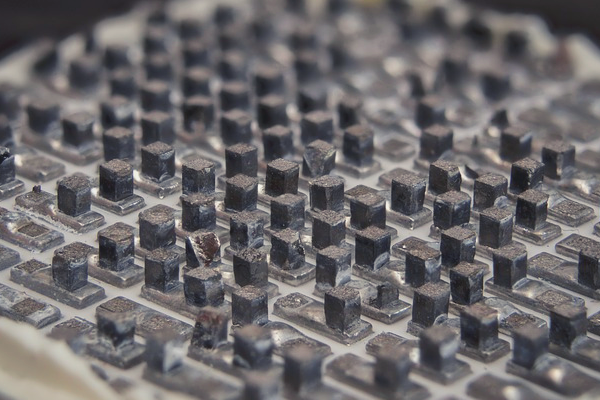

Thermoelectric cooling (TEC) became a viable option for spot cooling in the late 1950s with the development of semiconductor materials. The thermoelectric cooler (TEC), often called the Peltier module, is named after Jean Peltier who discovered heating/cooling effect when passing electric current through the junction of two conductors in the early 1800s. It is a semiconductor-based electronic component that functions as a small heat pump.

Using a low-voltage positive DC voltage to a TEC, electrons pass from one element (p-type) to another (n-type), and the cold-side temperature decreases as the electron current absorbs heat, until equilibrium is reached. The cooling is proportional to the current and the number of thermoelectric couples. This heat is transferred to the hot side of the cooler, where it is dissipated into the heat sink and surrounding environment. The result is a quick and large temperature differential.

Factors in Selection:

To use Thermoelectric spot cooling, a DC voltage required. This type of spot cooling is ideal when refrigerants are not desired, and space is limited. It a cost effective, reliable, efficient way to spot cool. Multiple thermoelectric coolers are connected side by side and then placed between two metal plates. It is ideal for intermittent heating and cooling applications because TEC seamlessly switches between heating and cooling.

Advantages:

Thermoelectric spot cooling has come to dominate certain applications because of the following benefits:

- Precise temperature control and stabilization to 0.01 degree C

- reliable

- noise-free operation

- vibration-free operation

- scalable

- compact

Choosing the best Spot Cooler

Applications:

TEC is used for spot cooling for the following applications:

- Telecommunication applications:

- 980nm and 1480nm Pump Lasers

- Digital Transmission Lasers

- Planar Lightwave Circuits

- Optical Channel Monitors

- CATV Transmission Lasers

- Avalanche Photodiodes

- Wavelength Lockers

- Medical samples

- Cold storage

- Electronic cabinets

- Self-powered appliances

- Small scale refrigeration

- Harsh environmental protection for critical components

- Computer microprocessors and robotics

- Cabinet cooling

Cryogenic Cooling (Carbon Dioxide or Nitrogen gas)

Cryogenics is the scientific study of materials and their behaviors at temperatures well below conventional refrigeration. The word comes from the Greek cryo “cold” and “genic”, which means “producing”. Cryogenic temperature ranges can be reported using any temperature scale, but Kelvin and Rankine scales are most commonly used because they are absolute scales that have only positive numbers. The U.S. National Institute of Standards and Technology (NIST) considers cryogenics to include temperatures below −180 °C (93.15 K; −292.00 °F), which is a temperature above which common refrigerants (e.g., hydrogen sulfide, freon) are gases and below which “permanent gases” (e.g., air, nitrogen, oxygen, neon, hydrogen, helium) are liquids. At 250 F below zero, many gases are liquid. Below is a list of temperatures where these gases boil.

| Fluid | Boiling (Celsius) | Boiling (Fahrenheit) |

| Oxygen | -183° | -297° |

| Nitrogen | -196° | -320° |

| Neon | -246° | -411° |

| Hydrogen | -253° | -423° |

| Helium | -270° | -452° |

Before the fluid’s temperature rise, all the liquid must boil away and turn into a gas. None of these gases exist naturally as a liquid. Each of the gases are cooled to put them into a liquid state.

Latent heat absorption during the phase change from solid to liquid or liquid to gas causes cooling in the immediate area. According to the American Society of Heating, Refrigerating and Air Conditioning Engineers (ASHRAE), liquid CO2 (LCO2), known as Refrigerant R-744, is the most widely used method used during vaporization of a liquid to a gas. When liquid CO2 is introduced to the system through the nozzle of a spray gun or cooling injector tube on a temperature chamber or thermal platform (cold plate), the liquid quickly turns to solid state CO2 or dry ice. As the dry ice warms up or sublimates (direct change from solid to gas), a great release of the latent heat occurs.

Latent heat absorption during the phase change from solid to liquid or liquid to gas causes cooling in the immediate area. According to the American Society of Heating, Refrigerating and Air Conditioning Engineers (ASHRAE), liquid CO2 (LCO2), known as Refrigerant R-744, is the most widely used method used during vaporization of a liquid to a gas. When liquid CO2 is introduced to the system through the nozzle of a spray gun or cooling injector tube on a temperature chamber or thermal platform (cold plate), the liquid quickly turns to solid state CO2 or dry ice. As the dry ice warms up or sublimates (direct change from solid to gas), a great release of the latent heat occurs.

Liquid CO2:

Spot-cooling method uses liquid CO2 injected in controlled pulses through tiny capillary tubes inserted into hard-to-cool areas to the same level as the rest of plastic mold cores. This approach is meant to complement conventional water cooling by ensuring uniform mold temperature without hot spots.

When the cooling cycle begins, LCO2 is fed under high pressure (approximately 850 psi (58.6 bar)) through the thin, flexible stainless-steel capillary tubes with solenoid valves to time injections and to the points where cooling is required. The high sublimation energy of the CO2 from solid to gas phase, along with the resulting cold gas, provides a very high local cooling capacity. The CO2 withdraws heat from the steel of the mold and escapes out of the expansion room in gaseous form through an annular gap between the hole and capillary tube.

Liquid Nitrogen:

Under normal atmospheric pressure, Nitrogen can exist as a liquid between the temperatures of 63 K and 77.2 K (-346°F and -320.44°F). Below 63 K, nitrogen freezes and becomes a solid. Above 77.2 K, nitrogen boils and becomes a gas. Since it is obtained from the atmosphere, liquid nitrogen is inexpensive and is rarely refrigerated. It is kept in insulated containers called Dewars and can boil away.

Advantages:

Given the purity of LCO2 supplied for this application (typically >99.98%), there is little danger of residue build-up or contamination of the hole as there would be with water cooling. Meanwhile, Liquid Nitrogen is colorless, odorless, and tasteless. It is an Inert element that is noncorrosive and does not support combustion, so it is safe.

Disadvantages:

There are several risks involved in cooling using cryogenic cooling systems. There is always a risk of asphyxiation, frostbite, or burns if not used and handled properly. Cryogenic gas has large expansion ratio for evaporation. For example, if one liter of liquid nitrogen can result in 700 liters of gas. If released in a small room, it can fill a room and make it an oxygen deficient atmosphere. It is also not safe to digest. It is essential that all the liquid nitrogen is evaporated before ingested otherwise it can boil and cause damage to internal organs.

Choosing the best Spot Cooler

Factors in Selection:

Cryogenic spot cooling systems are ideal for specific applications in automotive, medical, aerospace, consumer products, plumbing, and construction. CO2 is the preferred coolant for spot cooling because it is cheap to capture and compress. It is also ideal for large scale applications due to lower volume cost and longer storage times. The cooling requirements should be above -50 C. For repeated cooling, CO2 must be supplied at the right pressure and at the right temperature without gas bubbles. It stores longer than liquid nitrogen gas, which is stored at -190 C.

Liquid Nitrogen cryogenics is colder and has greater heat removing capabilities below -60˚C. Proper supply and control system design is crucial because if too much coolant sublimates to a solid state at once, blockages in the cooling system can occur.

It is highly recommended that oxygen monitoring equipment is used to test for oxygen deficient atmospheres during cryogenic spot cooling. The system must be properly maintained to prevent blockages.

Applications:

Applications of cryogenic spot cooling include:

- Cooling of construction mold

- Preserve experimental samples

- Coolant for computers

- Medicine to removed unwanted skin, warts, and pre-cancerous cells

- Instantly freeze food and cocktails – creating an impressive cloud of vapor or fog when exposed to air.

- Internet searches will find recipes for nitro-caramel popcorn and pumpkin-pie ice-cream

- Plastic and rubber deflashing and grinding

- Metal treating

- Biological sample preservation

- Pulverization

Summary

Vortex Tube cooling system is a low-cost choice for industrial applications. Simply adjust the hot end hot air valve to determine the temperature at the cold end. The more air escaping from the hot end reduces the temperature of the cold air flowing from the other end of the Vortex Tube.

It produces cold air instantly for enclosed environments. Since there are no moving parts, there is no spark or explosion hazard. Vortex Tube cooling system have two types of generators that are easily interchangeable. One generator has a cooling effect while the other one restricts the flow of the cold air, which creates extreme cold temperatures such as -40 or -50 F. Apart from special designs, the technology is available in the following configurations:

- Packaged Frigid-X® Panel Cooler for cooling control panels

- Packaged as an adjustable spot cooler

- Packaged as a tool cooler or mini cooler

- Packaged as a mist cooler

When you need require extreme cold temperatures, Nex Flow recommends using the Frigid-X® 50000C series. Nex flow vortex tub cooling system consists of a stainless-steel body with all metal parts. The cooling system is quiet and instantly creates sub-zero cold air temperatures from an ordinary compressed air supply for spot air cooling applications where precise adjustability of temperatures is important.

Like the Vortex Tube cooling system, Thermoelectric spot cooling is an ideal choice for intermittent cooling/heating applications. The disadvantage is that TEC requires a DC voltage because multiple thermoelectric coolers are connected side by side and then placed between two metal plates. Although equally effective for cooling to extreme temperatures as Vortex Tube or thermoelectric cooling systems for many industrial applications, cryogenic cooling appears to have the highest risks and the greatest need for monitoring equipment for health and safety concerns.

Nex Flow specializes in research and development of cooling technology required for industrial fic applications, such as spot cooling. Nex Flow® stays ahead of the competition by finding new applications for this unique technology, and to improve the efficiency of the products which depends on many proprietary factors. Corrosion-resistant, food-grade stainless steel means that all Nex Flow equipment is dependable, and long lasting. All spot cooling equipment is precision machined, assembled, and tested. Manufactured to withstand extreme temperatures and environmental conditions, the Vortex Tube cooling system is produced under strict quality control, which ensures years of reliable maintenance free operation.