How can panel coolers prevent factory downtime?

Electrical and electronic control panels are the heart of factory production. Any problems that occur with them can cause minor to major production hiccups, slow downs and potential need for a factory shut down. Just as you would take care of your own heart, it only makes sense that you recognize the heart of production and take good care of it.

But often this does not happen. How many times do you see control panel doors left open because they get “hot” inside. This creates a potential safety hazard and if the environment is not clean, it may cause dirt buildup inside the panels, on the controls – eventually leading to potential costly, premature failure.

As often as not, these control panels that are left open due to heat buildup is because of a lack of maintenance on whatever cooling system they may already have. It could be a simple external fans, external blowers, or traditional panel air conditioners. Even with water cooled systems, maintenance is necessary. External fans need filters, especially in dirty environments and these filters get dirty and require regular cleaning and/or replacement. Similarly with blowers, perhaps even more often. Water cooled systems have small water lines and can scale up, preventing adequate cooling. Traditional air conditions are an even more critical machines for regular maintenance. Not only do filters need to be cleaned and/or changed regularly, especially in dirty environments, if air conditioners are on machines that have vibration the refrigerant inside may leak out the unit. It is important to recognize the cost of the smallest downtime due to a control panel “going down”.

So what can be done? If whatever cooling system is working well and you do not have issues with control panels overheating, then of course nothing. Keep doing what you are doing. But if you have even once have to open a cabinet door to vent out some heat – then you have a problem. Would you ignore a sharp pain in your own heart? Well, that overheating is the panel’s pain.

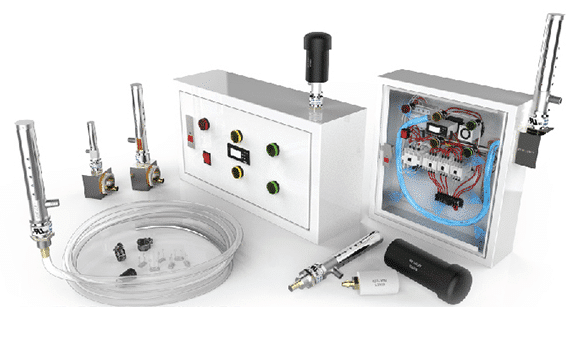

One solution is to overhaul the maintenance program on the control panels as that can certainly be a source of the problem but that in itself may reveal and create other costs. But it is one option. Another option is to use a Nex Flow Panel Cooler.

Despite the use of compressed air for operation the Nex Flow Panel Cooler is essentially maintenance free. Once installed, it can be left to operate under the worst conditions of a dirty factory environment, with high humidity, high ambient temperature and even on equipment that vibrates. How it works is simple – compressed air enters the Nex Flow Panel Cooler and the vortex tube component separates the compressed air into a hot and cold stream. The hot end is exhausted as waste but the cold air goes inside the control panel to cool and keep the cabinet from overheating. The connection to the cabinet has a built in exhaust to vent out the hot air displaced by the cold air. Since there are no moving parts, and no refrigerant chemical inside the unit, the Panel Cooler can handle equipment vibration. The air entering the cabinet keeps the cabinet at a slightly positive pressure keeping out any humidity and any dirt and particulate in the environment. The effectiveness of the air conditioning depends solely on the temperature of the compressed air and not the environment making Panel Coolers ideal to use in hot and humid locations. There is no condensate produced that needs to be disposed of and you do not have to worry about replacing filters. The only basic requirement is to properly filter the supplied compressed air. To conserve energy, a thermostat and solenoid valve control system can turn the air on and off as required. Alternatively an electronic thermostat system can be used. To keep the cabinet constantly at positive pressure to keep out a very nasty environment, a bypass system can be installed around the solenoid to always have a very small amount of compressed air flowing even when the unit is off.

If maintenance is not adequate or perhaps the environment is just so unfriendly it causes serious and costly issues for whatever the reason for problems with traditional air conditioning or other cooling systems, the Nex Flow Panel Cooler can be a viable option and the extra energy costs often offset by the shorter life span, or damage to controls and other problems created using other systems.