Product Overview

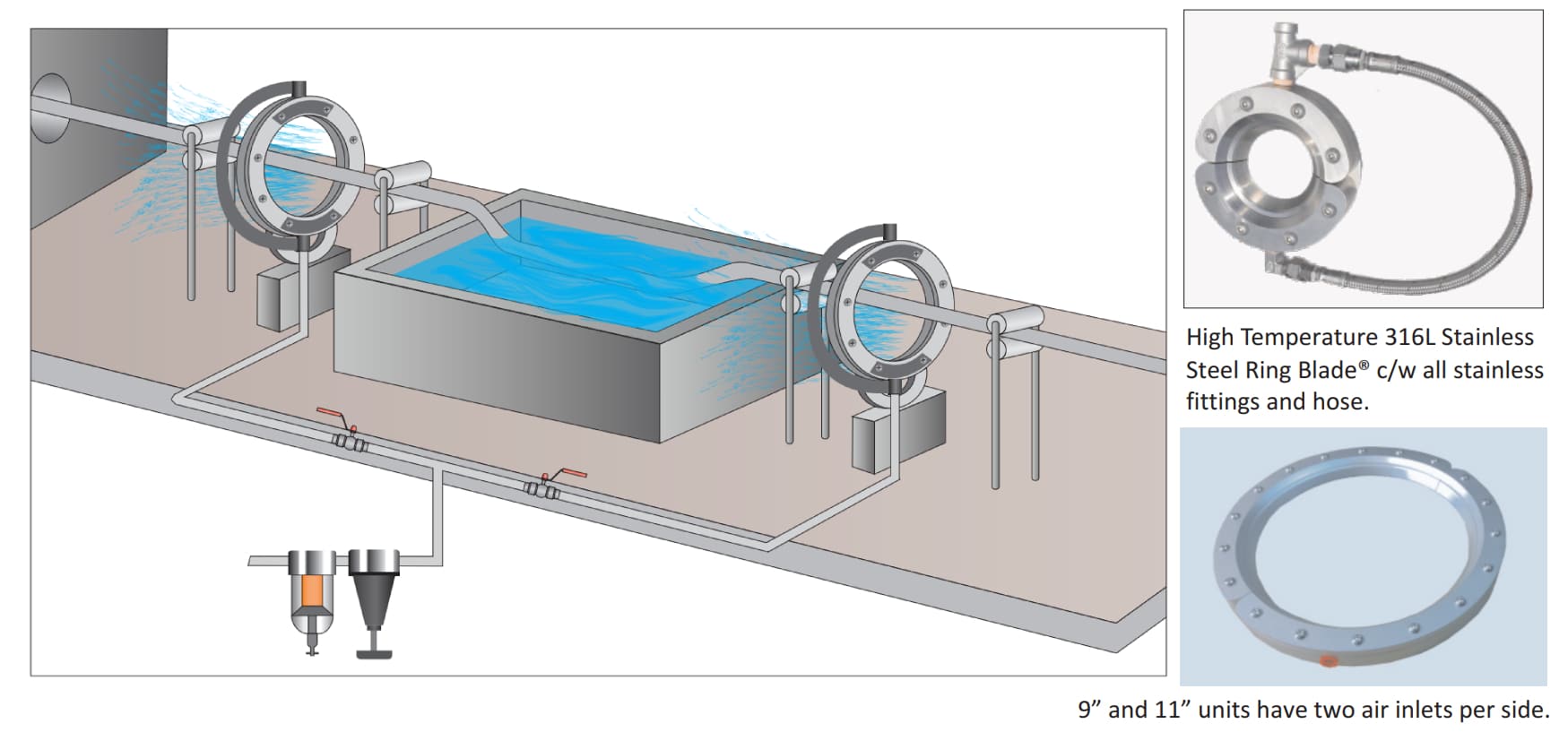

The Nex Flow®’s Ring Blade® Air Wipe is a lightweight, compact, and easy to install, piece of equipment that produces an even 360 degree blow off around the part. It reduces compressed air use for energy saving as well as significantly lowers noise levels. The systems are essentially maintenance free with blow off output easily controlled with a regulator.

Air wipes are basically air knives arranged in an annular form – like Air Amplifiers – but split into two half circles and then joined together. These units are used as efficient blow-off system for all types of extrusions – wire, cable rope, window profiles, automotive trip, extruded pipe, and other applications. Nex Flow® produces sizes from 3/8” diameter to 11” diameter as a standard and have produced special sizes when necessary.

They are designed as two separate pieces hinged together to open and close around the extruded or moving part. Instant on-off with no moving parts, The 360 Degree Air Wipe System produces a “laminar” flow of air along its 360º angle using the “Coanda” effect which “entrains” a large volume of air from the surrounding area along with the small amount of compressed air from the Air Wipe System to produce an output flow up to 30 times the compressed air input. The blow off is angled against the direction of flow of the part to shear off moisture and dirt effectively, even for irregular shaped parts.

Available in 10 standard (inside) diameters AND in 3 Versions

Special diameters for the Air Wipe Blow-Off System are available on special request from Nex Flow®.

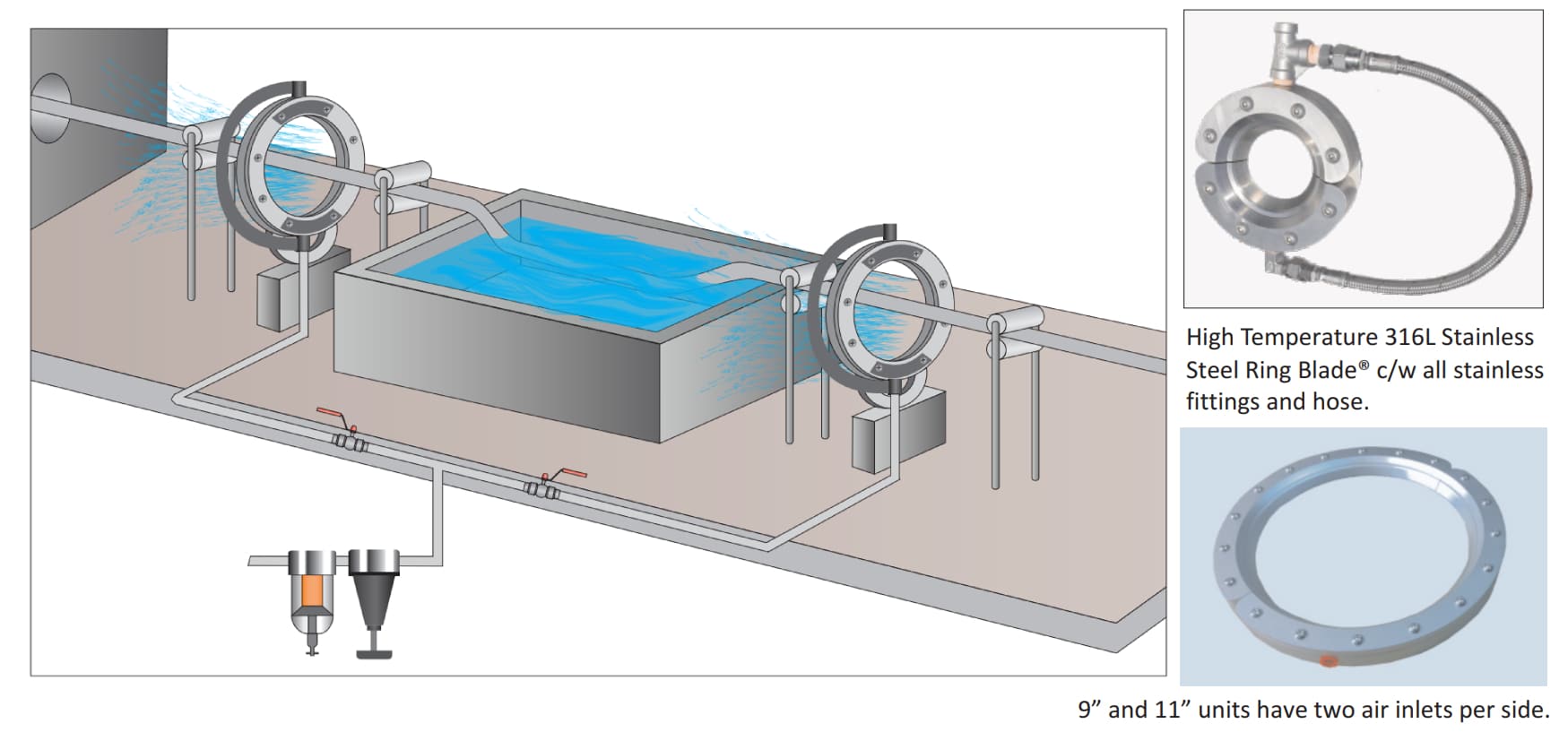

Each Ring Blade® comes with a standard .002″ outlet gap which will work for 90% of all applications encountered. If greater force is required, a second .002″ (.05mm) shim may be installed to open the gap for greater flow and force. Materials of construction are anodized aluminum or 316L stainless steel.

Applications

- Drying after wash, cleaning, plating or coating

- Blow off dust and contaminants

- Cool hot extruded shapes

- Uniformly wipe surfaces

- Dry extruded profiles, rod and medical tubing

- Blow excess water from automotive door gaskets

- Remove excess coatings, water and oil

- Dry tube, hose, wire, fiber optics

- Clean paint gun tips

- Dry screen printed or ink jetted surfaces

- Clean strips and ribbon

Features / Advantages

- Quiet

- Low air consumption

- Uniform airflow across the entire diameter

- No electricity, no moving parts

- Non-contact – no wiper blade

- Lightweight, low profile

- Split design – compact, rugged, easy to install

- Stainless steel hardware resists corrosion

Videos

How The Nex Flow® Ring-Blade® Air Blow-Off System Works

Compressed air enters at point (A) into an annular chamber and throttled through a small ring nozzle at high velocity. This air stream clings to the Coanda profile directing the air stream down toward the surface which is angled to create a “cone” style directed force to best clean, wipe and dry a surface. The surrounding air is entrained at point (B) creating an amplified 360-degree conical airflow at point (C) to uniformly wipe the surface of the of the material running through the Ring Blade®. The wet or dirty material (D) direction of travel is against the flow.

Performance

Air Consumption Inlet Pressure 80 PSIG (5.5BAR)

| Size (Internal) Diameter In Inches (mm) | Air Consumption per unit with std. .002″ (.05mm) gap | Air Consumption per unit. with .004″ (.10mm)gap (shim added) | Sound Level @3FT dBA |

|---|---|---|---|

| 3/8″ (9.5mm) | 11.1 SCFM (314 SLPM ) | 22 SCFM (628 SLPM) | 82 |

| 1/2″ (12.7mm) | 14 SCFM (396 SLPM ) | 28 SCFM (793 SLPM) | 80 |

| 1″ (25.4mm) | 19 SCFM (538 SLPM) | 38 SCFM (1076 SLPM) | 80 |

| 2″ (50.8mm) | 30 SCFM (850 SLPM) | 60 SCFM (1699 SLPM) | 81 |

| 3″ (76mm) | 40 SCFM (1132 SLPM) | 80 SCFM (2265 SLPM) | 82 |

| 4″ (102mm) | 51 SCFM (1444 SLPM) | 102 SCFM(2888 SLPM) | 82 |

| 5″ (127mm) | 60 SCFM (1700 SLPM) | 120 SCFM (3398 SLPM) | 82 |

| 6″ (152mm) | 71 SCFM (2010) SLPM) | 142 SCFM (4021 SLPM) | 84 |

| 7″ (178mm) | 80 SCFM (2266 SLPM) | 160 SCFM (4532 SLPM) | 85 |

| 9″ (229mm) | 102 SCFM(2880 SLPM) | 204 SCFM (5760 SLPM) | 87 |

| 11″ (279mm) | 123 SCFM (3480 SLPM) | 246 SCFM (6560 SLPM) | 89 |

Based on an Amplification Ratio of 30:1 the air flow out would be 30 times the above.

Dimensions

| Standard Applications | X-Stream Moderate TEMP. to 400°F (204°C) | 316L Stainless High TEMP. to 800°F (427°C) and Corrosive Environments | A Inches (mm) | B Inches (mm) | C Inches (mm) | Compressed Air Connection |

|---|---|---|---|---|---|---|

| 29999 | 29999X | N/A | 0.83″ (9.5) |

2.69″ (68.3) |

2.50″ (63.5) |

1/4” NPT |

| 20000 | 20000X | 20000XS-316L | 0.50” (12.7) | 3.25″ (82.6) | 2.63″ (66.8) | 1/4” NPT |

| 20001 | 20001X | 20001XS-316L | 1.00” (25.4) | 3.75″ (95.3) | 3.00″ (76.2) | 1/4” NPT |

| 20002 | 20002X | 20002XS-316L | 2.00″ (50.8) | 4.75″ (121) | 4.00” (102.6) | 1/4” NPT |

| 20003 | 20003X | 20003XS-316L | 3.00″ (76.2) | 5.75″ (146) | 5.00″ (127) | 1/4” NPT |

| 20004 | 20004X | 20004XS-316L | 4.00″ (102.6) | 6.75″ (171) | 6.00″ (153) | 1/4” NPT |

| 20005 | 20005X | 20005XS-316L | 5.00″ (127.0) | 7.75″ (197) | 7.00″ (178) | 3/8” NPT |

| 20006 | 20006X | 20006XS-316L | 6.00″ (153) | 8.75″ (222) | 8.00″ (203) | 3/8” NPT |

| 20007 | 20007X | 20007XS-316L | 7.00″ (178) | 9.75″ (248) | 9.00″ (229) | 3/8” NPT |

| 20009 | 20009X | – | 9.00″ (229) | 11.75″ (298.5) | 11.00″ (279) | 4×1/4” NPT |

| 20011 | 20011X | – | 11.00″ (279) | 13.75″ (349) | 13.00″ (330) | 4×1/4” NPT |

| Aluminum Ring Blade® Air Wipe Systems – up to 150 F (66℃) | |||

|---|---|---|---|

| PART NO. | DESCRIPTION | SIZE | PRICE US DOLLARS |

| 29999 | Aluminum Ring Blade Only | 3/8" | $248.00 |

| 20000 | Aluminum Ring Blade Only | 1/2″ | $266.00 |

| 20001 | Aluminum Ring Blade Only | 1″ | $282.00 |

| 20002 | Aluminum Ring Blade Only | 2″ | $398.00 |

| 20003 | Aluminum Ring Blade Only | 3″ | $638.00 |

| 20004 | Aluminum Ring Blade Only | 4″ | $892.00 |

| 20005 | Aluminum Ring Blade Only | 5″ | $1,172.00 |

| 20006 | Aluminum Ring Blade Only | 6″ | $1,475.00 |

| 20007 | Aluminum Ring Blade Only | 7″ | $1,850.00 |

| 20009 | Aluminum Ring Blade Only (Optional hose assemby) * | 9″ | $2,705.00 |

| 20011 | Aluminum Ring Blade Only (Optional hose assemby) * | 11″ | $3,690.00 |

| 20009-29002-DA | Aluminum Ring Blade Only with c/w Optional Double Hose Assembly | 9" | $3,155.00 |

| 20011-29002-DA | Aluminum Ring Blade Only with c/w Optional Double Hose Assembly | 11" | $4,140.00 |

| * 20009 & 20011 also good for medium temperature range with no hose assembly provided - rubber hose assembly optional and stainless steel assembly is provided for aluminum medium and high stainless steel temperature 9" and 11" models* | |||

| 21999 | Al. Ring Bl. Plus filter with auto drain model 90004 | 3/8" | $373.00 |

| 21000 | Al. Ring Bl. Plus filter with auto drain model 90004 | 1/2″ | $391.00 |

| 21001 | Al. Ring Bl. Plus filter with auto drain model 90004 | 1″ | $407.00 |

| 21002 | Al. Ring Bl. Plus filter with auto drain model 90001 | 2″ | $523.00 |

| 21003 | Al. Ring Bl. Plus filter with auto drain model 90002 | 3″ | $863.00 |

| 21004 | Al. Ring Bl. Plus filter with auto drain model 90002 | 4″ | $1,117.00 |

| 21005 | Al. Ring Bl. Plus filter with auto drain model 90002 | 5″ | $1,397.00 |

| 21006 | Al. Ring Bl. Plus filter with auto drain model 90002 | 6″ | $1,700.00 |

| 21007 | Al. Ring Bl. Plus filter with auto drain model 90002 | 7″ | $2,075.00 |

| 21009 | Al. Ring Bl. Plus filter with auto drain model 90002 (Optional hose assemby) * | 9" | $2,930.00 |

| 21011 | Al. Ring Bl. Plus filter with auto drain model 90002 (Optional hose assemby) * | 11" | $3,915.00 |

| 21009-29002-DA | Al. Ring Bl. Plus filter with auto drain model 90002 c/w Optional Double Hose Assembly | 9" | $3,380.00 |

| 21011-29002-DA | Al. Ring Bl. Plus filter with auto drain model 90002 c/w Optional Double Hose Assembly | 11" | $4,365.00 |

| 22999 | Al. Ring Bl. + filter 90004 + regulator with gage model 90008 | 3/8" | $448.00 |

| 22000 | Al. Ring Bl. + filter 90004 + regulator with gage model 90008 | 1/2″ | $466.00 |

| 22001 | Al. Ring Bl. + filter 90004 + regulator with gage model 90008 | 1″ | $482.00 |

| 22002 | Al. Ring Bl. + filter 90001 + regulator with gage model 90008 | 2″ | $598.00 |

| 22003 | Al. Ring Bl. + filter 90002+ regulator with gage model 90009 | 3″ | $973.00 |

| 22004 | Al. Ring Bl. + filter 90002 + regulator with gage model 90009 | 4″ | $1,227.00 |

| 22005 | Al. Ring Bl. + filter 90002 + regulator with gage model 90009 | 5″ | $1,507.00 |

| 22006 | Al. Ring Bl. + filter 90002 + regulator with gage model 90009 | 6″ | $1,810.00 |

| 22007 | Al. Ring Bl. + filter 90002 + regulator with gage model 90009 | 7″ | $2,185.00 |

| 22009 | Al. Ring Bl. + filter 90002 + regulator with gage model 90009 (Optional hose assemby) * | 9" | $3,040.00 |

| 22011 | Al. Ring Bl. + filter 90002 + regulator with gage model 90009 (Optional hose assemby) * | 11" | $4,025.00 |

| 22009-29002-DA | Al. Ring Bl. + filter 90002 + regulator with gage model 90009 c/w Optional Double Hose Assembly | 9" | $3,490.00 |

| 22011-29002-DA | Al. Ring Bl. + filter 90002 + regulator with gage model 90009 c/w Optional Double Hose Assembly | 11" | $4,475.00 |

| More Information or Buy Here |

| X-Stream Ring Blade® Air Wipe Systems – up to 400 F (204℃) | |||

|---|---|---|---|

| PART NO. | DESCRIPTION | SIZE | PRICE US DOLLARS |

| 29999X | X-Stream Ring Blade with stainless hose & shim, brass fittings | 3/8" | $372.00 |

| 20000X | X-Stream Ring Blade with stainless hose & shim, brass fittings | 1/2″ | $395.00 |

| 20001X | X-Stream Ring Blade with stainless hose & shim, brass fittings | 1″ | $421.00 |

| 20002X | X-Stream Ring Blade with stainless hose & shim, brass fittings | 2″ | $520.00 |

| 20003X | X-Stream Ring Blade with stainless hose & shim, brass fittings | 3″ | $850.00 |

| 20004X | X-Stream Ring Blade with stainless hose & shim, brass fittings | 4″ | $1,200.00 |

| 20005X | X-Stream Ring Blade with stainless hose & shim, brass fittings | 5″ | $1,600.00 |

| 20006X | X-Stream Ring Blade with stainless hose & shim, brass fittings | 6″ | $1,900.00 |

| 20007X | X-Stream Ring Blade with stainless hose & shim, brass fittings | 7″ | $2,100.00 |

| 20009X-29002XS-DA | X-Stream Ring Blade with stainless hose & shim, brass fittings (Optional Double SS Hose Assembly) * | 9" | $3,555.00 |

| 20011X-29002XS-DA | X-Stream Ring Blade with stainless hose & shim, brass fittings (Optional Double SS Hose Assembly) * | 11" | $4,540.00 |

| 21999X | X-Stream Ring Bl. Plus filter with auto drain model 90004 | 3/8" | $497.00 |

| 21000X | X-Stream Ring Bl. Plus filter with auto drain model 90004 | 1/2″ | $520.00 |

| 21001X | X-Stream Ring Bl. Plus filter with auto drain model 90004 | 1″ | $546.00 |

| 21002X | X-Stream Ring Bl. Plus filter with auto drain model 90001 | 2″ | $645.00 |

| 21003X | X-Stream Ring Bl. Plus filter with auto drain model 90002 | 3″ | $1,075.00 |

| 21004X | X-Stream Ring Bl. Plus filter with auto drain model 90002 | 4″ | $1,425.00 |

| 21005X | X-Stream Ring Bl. Plus filter with auto drain model 90002 | 5″ | $1,825.00 |

| 21006X | X-Stream Ring Bl. Plus filter with auto drain model 90002 | 6″ | $2,125.00 |

| 21007X | X-Stream Ring Bl. Plus filter with auto drain model 90002 | 7″ | $2,325.00 |

| 21009XS-29002XS-DA | X-Stream Ring Bl. Plus filter with auto drain model 90002 (Optional Double SS Hose Assembly) * | 9" | $3,780.00 |

| 21011XS-29002XS-DA | X-Stream Ring Bl. Plus filter with auto drain model 90002 (Optional Double SS Hose Assembly) * | 11" | $4,765.00 |

| 22999X | X-Stream Ring Bl. + filter 90004 + reg. with gage model 90008 | 3/8" | $572.00 |

| 22000X | X-Stream Ring Bl. + filter 90004 + reg. with gage model 90008 | 1/2″ | $595.00 |

| 22001X | X-Stream Ring Bl. + filter 90004 + reg. with gage model 90008 | 1″ | $621.00 |

| 22002X | X-Stream Ring Bl. + filter 90001 + reg. with gage model 90008 | 2″ | $720.00 |

| 22003X | X-Stream Ring Bl. + filter 90002+ reg. with gage model 90009 | 3″ | $1,185.00 |

| 22004X | X-Stream Ring Bl. + filter 90002 + reg. with gage model 90009 | 4″ | $1,535.00 |

| 22005X | X-Stream Ring Bl. + filter 90002 + reg. with gage model 90009 | 5″ | $1,935.00 |

| 22006X | X-Stream Ring Bl. + filter 90002 + reg. with gage model 90009 | 6″ | $2,235.00 |

| 22007X | X-Stream Ring Bl. + filter 90002 + reg. with gage model 90009 | 7″ | $2,435.00 |

| 22009XS-29002XS-DA | X-Stream Ring Bl. + filter 90002 + reg. with gage model 90009 (Optional Double SS Hose Assembly) * | 9" | $3,890.00 |

| 22011XS-29002XS-DA | X-Stream Ring Bl. + filter 90002 + reg. with gage model 90009 (Optional Double SS Hose Assembly) * | 11" | $4,875.00 |

| More Information or Buy Here |

| Extra Stainless Steel Shims – .002” (.050 mm) for Ring Blade™ Air Wipe Systems | |||

|---|---|---|---|

| PART NO. | DESCRIPTION | SIZE | PRICE US DOLLARS |

| 20999 | Stainless Steel Shim – .002″ thick (EACH) | 3/8" | $14.00 |

| 20100 | Stainless Steel Shim – .002″ thick (EACH) | 1/2" | $14.00 |

| 20101 | Stainless Steel Shim – .002″ thick (EACH) | 1" | $16.00 |

| 20102 | Stainless Steel Shim – .002″ thick (EACH) | 2" | $18.00 |

| 20103 | Stainless Steel Shim – .002″ thick (EACH) | 3" | $24.00 |

| 20104 | Stainless Steel Shim – .002″ thick (EACH) | 4" | $28.00 |

| 20105 | Stainless Steel Shim – .002″ thick (EACH) | 5" | $32.00 |

| 20106 | Stainless Steel Shim – .002″ thick (EACH) | 6" | $38.00 |

| 20107 | Stainless Steel Shim – .002″ thick (EACH) | 7" | $45.00 |

| 20109 | Stainless Steel Shim – .002″ thick (EACH) | 9" | $52.00 |

| 20111 | Stainless Steel Shim – .002″ thick (EACH) | 11" | $64.00 |

| 20999K | Stainless Steel Shim - .002" thick (TWO SHIMS) | 3/8" | $28.00 |

| 20100K | Stainless Steel Shim - .002" thick (TWO SHIMS) | 1/2" | $28.00 |

| 20101K | Stainless Steel Shim - .002" thick (TWO SHIMS) | 1" | $32.00 |

| 20102K | Stainless Steel Shim - .002" thick (TWO SHIMS) | 2" | $36.00 |

| 20103K | Stainless Steel Shim - .002" thick (TWO SHIMS) | 3" | $48.00 |

| 20104K | Stainless Steel Shim - .002" thick (TWO SHIMS) | 4" | $56.00 |

| 20105K | Stainless Steel Shim - .002" thick (TWO SHIMS) | 5" | $64.00 |

| 20106K | Stainless Steel Shim - .002" thick (TWO SHIMS) | 6" | $76.00 |

| 20107K | Stainless Steel Shim - .002" thick (TWO SHIMS) | 7" | $90.00 |

| 20109K | Stainless Steel Shim - .002" thick (TWO SHIMS) | 9" | $104.00 |

| 20111K | Stainless Steel Shim - .002" thick (TWO SHIMS) | 11" | $128.00 |

| More Information or Buy Here |

| Stainless Steel Ring Blade™ Air Wipe Systems – up to 800 F (427℃) | |||

|---|---|---|---|

| PART NO. | DESCRIPTION | SIZE | PRICE US DOLLARS |

| 29999XS-316L | 316l. Stainless Steel Ring Blade with316L stainless hose & shims & fittings | 3/8" | $840.00 |

| 20000XS-316L | 316l. Stainless Steel Ring Blade with316L stainless hose & shims & fittings | 1/2″ | $850.00 |

| 20001XS-316L | 316l. Stainless Steel Ring Blade with 316L stainless hose & shims & fittings | 1″ | $950.00 |

| 20002XS-316L | 316l. Stainless Steel Ring Blade with 316L stainless hose & shims & fittings | 2″ | $1,250.00 |

| 20003XS-316L | 316l. Stainless Steel Ring Blade with 316L stainless hose & shims & fittings | 3″ | $1,825.00 |

| 20004XS-316L | 316l. Stainless Steel Ring Blade with 316L stainless hose & shims & fittings | 4″ | $2,525.00 |

| 20005XS-316L | 316l. Stainless Steel Ring Blade with 316L stainless hose & shims & fittings | 5″ | $3,250.00 |

| 20006XS-316L | 316l. Stainless Steel Ring Blade with 316L stainless hose & shims & fittings | 6″ | $4,290.00 |

| 20007XS-316L | 316l. Stainless Steel Ring Blade with 316L stainless hose & shims & fittings | 7″ | $4,450.00 |

| 20009XS-316L | 316l. Stainless Steel Ring Blade with 316L stainless hose & shims & fittings (Optional SS hose assembly) * | 9" | $4,800.00 |

| 20011XS-316L | 316l. Stainless Steel Ring Blade with 316L stainless hose & shims & fittings (Optional SS hose assemby) * | 11" | $5,200.00 |

| 20009XS-29002XS-DA | 316l. SSS Ring Blade with316L SS Hose/shims/fittings c/w Optional SS Double Hose Assembly | 9" | $5,650.00 |

| 20011XS-29002XS-DA | 316l. SSS Ring Blade with316L SS Hose/shims/fittings c/w Optional SS Double Hose Assembly | 11" | $6,050.00 |

| 21999XS-316L | 316l. Stainless Steel Ring Bl. Plus filter with auto drain model 90004 | 3/8" | $965.00 |

| 21000XS-316L | 316L Stainless Steel Ring Bl. Plus filter with auto drain model 90004 | 1/2″ | $975.00 |

| 21001XS-316L | 316L Stainless Steel Ring Bl. Plus filter with auto drain model 90004 | 1″ | $1,075.00 |

| 21002XS-316L | 316L Stainless Steel Ring Bl. Plus filter with auto drain model 90001 | 2″ | $1,375.00 |

| 21003XS-316L | 316L Stainless Steel Ring Bl. Plus filter with auto drain model 90002 | 3″ | $2,050.00 |

| 21004XS-316L | 316L Stainless Steel Ring Bl. Plus filter with auto drain model 90002 | 4″ | $2,750.00 |

| 21005XS-316L | 316L Stainless Steel Ring Bl. Plus filter with auto drain model 90002 | 5″ | $3,475.00 |

| 21006XS-316L | 316L Stainless Steel Ring Bl. Plus filter with auto drain model 90002 | 6″ | $4,515.00 |

| 21007XS-316L | 316L Stainless Steel Ring Bl. Plus filter with auto drain model 90002 | 7″ | $4,675.00 |

| 21009XS-316L | 316L Stainless Steel Ring Bl. Plus filter with auto drain model 90002 (Optional SS hose assemby) * | 9" | $5,025.00 |

| 21011XS-316L | 316L Stainless Steel Ring Bl. Plus filter with auto drain model 90002 (Optional SS hose assemby) * | 11" | $5,425.00 |

| 21009XS-29002XS-DA | 316L SS Ring Bl. Plus filter with auto drain model 90002 c/w Optional SS Double Hose Assembly | 9" | $5,875.00 |

| 21011XS-29002XS-DA | 316L SS Ring Bl. Plus filter with auto drain model 90002 c/w Optional SS Double Hose Assembly | 11" | $6,275.00 |

| 22999XS-316L | 316l. SS Ring Bl. + filter 90004 + reg. with gage model 90008 | 3/8" | $1,040.00 |

| 22000XS-316L | 316L SS Ring Bl. + filter 90004 + reg. with gage model 90008 | 1/2″ | $1,050.00 |

| 22001XS-316L | 316L SS Ring Bl. + filter 90004 + reg. with gage model 90008 | 1″ | $1,150.00 |

| 22002XS-316L | 316L SS Ring Bl. + filter 90001 + reg. with gage model 90008 | 2″ | $1,450.00 |

| 22003XS-316L | 316L SS Ring Bl. + filter 90002 + reg. with gage model 90009 | 3″ | $2,160.00 |

| 22004XS-316L | 316L SS Ring Bl. + filter 90002 + reg. with gage model 90009 | 4″ | $2,860.00 |

| 22005XS-316L | 316L SS Ring Bl. + filter 90002 + reg. with gage model 90009 | 5″ | $3,585.00 |

| 22006XS-316L | 316L SS Ring Bl. + filter 90002 + reg. with gage model 90009 | 6″ | $4,625.00 |

| 22007XS-316L | 316L SS Ring Bl. + filter 90002 + reg. with gage model 90009 | 7″ | $4,785.00 |

| 22009XS-316L | 316L SS Ring Bl. + filter 90002 + reg. with gage model 90009 (Optional SS hose assemby) * | 9" | $5,135.00 |

| 22011XS-316L | 316L SS Ring Bl. + filter 90002 + reg. with gage model 90009 (Optional SS hose assemby) * | 11" | $5,535.00 |

| 22009XS-29002XS-DA | 316L SS Ring Bl. + filter 90002 + reg. with gage model 90009 c/w Optional SS Double Hose Assembly | 9" | $5,985.00 |

| 22011XS-29002XS-DA | 316L SS Ring Bl. + filter 90002 + reg, with gage model 90009 c/w Optional SS Double Hose Assembly | 11" | $6,385.00 |

| More Information or Buy Here |

| Extra 316L Stainless Steel Shims – .002” (.050 mm) for Stainless Ring Blade™ Air Wipe Systems | |||

|---|---|---|---|

| PART NO. | DESCRIPTION | SIZE | PRICE US DOLLARS |

| 20100-316L | Stainless Steel Shim - .002" thick (EACH) | 1/2" | $16.00 |

| 20101-316L | Stainless Steel Shim - .002" thick (EACH) | 1" | $18.00 |

| 20102-316L | Stainless Steel Shim - .002" thick (EACH) | 2" | $20.00 |

| 20103-316L | Stainless Steel Shim - .002" thick (EACH) | 3" | $26.00 |

| 20104-316L | Stainless Steel Shim - .002" thick (EACH) | 4" | $30.00 |

| 20105-316L | Stainless Steel Shim - .002" thick (EACH) | 5" | $34.00 |

| 20106-316L | Stainless Steel Shim - .002" thick (EACH) | 6" | $40.00 |

| 20107-316L | Stainless Steel Shim - .002" thick (EACH) | 7" | $44.00 |

| 20100-316LK | Stainless Steel Shim - .002" thick (EACH) (TWO SHIMS) | 1/2" | $32.00 |

| 20101-316LK | Stainless Steel Shim - .002" thick (EACH) (TWO SHIMS) | 1" | $36.00 |

| 20102-316LK | Stainless Steel Shim - .002" thick (EACH) (TWO SHIMS) | 2" | $40.00 |

| 20103-316LK | Stainless Steel Shim - .002" thick (EACH) (TWO SHIMS) | 3" | $52.00 |

| 20104-316LK | Stainless Steel Shim - .002" thick (EACH) (TWO SHIMS) | 4" | $60.00 |

| 20105-316LK | Stainless Steel Shim - .002" thick (EACH) (TWO SHIMS) | 5" | $68.00 |

| 20106-316LK | Stainless Steel Shim - .002" thick (EACH) (TWO SHIMS) | 6" | $80.00 |

| 20107-316LK | Stainless Steel Shim - .002" thick (EACH) (TWO SHIMS) | 7" | $88.00 |

| More Information or Buy Here |

Prices are in US dollars – ex works Cincinnati, OH, USA for orders in USA

Richmond Hill, ON, Canada for international orders.

website : www.nexflow.com

email : sales@nexflow.com

- Overview

-

Product Overview

The Nex Flow®’s Ring Blade® Air Wipe is a lightweight, compact, and easy to install, piece of equipment that produces an even 360 degree blow off around the part. It reduces compressed air use for energy saving as well as significantly lowers noise levels. The systems are essentially maintenance free with blow off output easily controlled with a regulator.

Air wipes are basically air knives arranged in an annular form – like Air Amplifiers – but split into two half circles and then joined together. These units are used as efficient blow-off system for all types of extrusions – wire, cable rope, window profiles, automotive trip, extruded pipe, and other applications. Nex Flow® produces sizes from 3/8” diameter to 11” diameter as a standard and have produced special sizes when necessary.

They are designed as two separate pieces hinged together to open and close around the extruded or moving part. Instant on-off with no moving parts, The 360 Degree Air Wipe System produces a “laminar” flow of air along its 360º angle using the “Coanda” effect which “entrains” a large volume of air from the surrounding area along with the small amount of compressed air from the Air Wipe System to produce an output flow up to 30 times the compressed air input. The blow off is angled against the direction of flow of the part to shear off moisture and dirt effectively, even for irregular shaped parts.

Available in 10 standard (inside) diameters AND in 3 Versions

Special diameters for the Air Wipe Blow-Off System are available on special request from Nex Flow®.

Each Ring Blade® comes with a standard .002″ outlet gap which will work for 90% of all applications encountered. If greater force is required, a second .002″ (.05mm) shim may be installed to open the gap for greater flow and force. Materials of construction are anodized aluminum or 316L stainless steel.

Applications

- Drying after wash, cleaning, plating or coating

- Blow off dust and contaminants

- Cool hot extruded shapes

- Uniformly wipe surfaces

- Dry extruded profiles, rod and medical tubing

- Blow excess water from automotive door gaskets

- Remove excess coatings, water and oil

- Dry tube, hose, wire, fiber optics

- Clean paint gun tips

- Dry screen printed or ink jetted surfaces

- Clean strips and ribbon

- Advantages

-

Features / Advantages

- Quiet

- Low air consumption

- Uniform airflow across the entire diameter

- No electricity, no moving parts

- Non-contact – no wiper blade

- Lightweight, low profile

- Split design – compact, rugged, easy to install

- Stainless steel hardware resists corrosion

- Videos

-

Videos

How The Nex Flow® Ring-Blade® Air Blow-Off System Works

Compressed air enters at point (A) into an annular chamber and throttled through a small ring nozzle at high velocity. This air stream clings to the Coanda profile directing the air stream down toward the surface which is angled to create a “cone” style directed force to best clean, wipe and dry a surface. The surrounding air is entrained at point (B) creating an amplified 360-degree conical airflow at point (C) to uniformly wipe the surface of the of the material running through the Ring Blade®. The wet or dirty material (D) direction of travel is against the flow.

- Performance

-

Performance

Air Consumption Inlet Pressure 80 PSIG (5.5BAR)

Size (Internal) Diameter In Inches (mm) Air Consumption per unit with std. .002″ (.05mm) gap Air Consumption per unit. with .004″ (.10mm)gap (shim added) Sound Level @3FT dBA 3/8″ (9.5mm) 11.1 SCFM (314 SLPM ) 22 SCFM (628 SLPM) 82 1/2″ (12.7mm) 14 SCFM (396 SLPM ) 28 SCFM (793 SLPM) 80 1″ (25.4mm) 19 SCFM (538 SLPM) 38 SCFM (1076 SLPM) 80 2″ (50.8mm) 30 SCFM (850 SLPM) 60 SCFM (1699 SLPM) 81 3″ (76mm) 40 SCFM (1132 SLPM) 80 SCFM (2265 SLPM) 82 4″ (102mm) 51 SCFM (1444 SLPM) 102 SCFM(2888 SLPM) 82 5″ (127mm) 60 SCFM (1700 SLPM) 120 SCFM (3398 SLPM) 82 6″ (152mm) 71 SCFM (2010) SLPM) 142 SCFM (4021 SLPM) 84 7″ (178mm) 80 SCFM (2266 SLPM) 160 SCFM (4532 SLPM) 85 9″ (229mm) 102 SCFM(2880 SLPM) 204 SCFM (5760 SLPM) 87 11″ (279mm) 123 SCFM (3480 SLPM) 246 SCFM (6560 SLPM) 89 Based on an Amplification Ratio of 30:1 the air flow out would be 30 times the above.

- Dimensions

-

Dimensions

Standard Applications X-Stream Moderate TEMP. to 400°F (204°C) 316L Stainless High TEMP. to 800°F (427°C) and Corrosive Environments A Inches (mm) B Inches (mm) C Inches (mm) Compressed Air Connection 29999 29999X N/A 0.83″

(9.5)2.69″

(68.3)2.50″

(63.5)1/4” NPT 20000 20000X 20000XS-316L 0.50” (12.7) 3.25″ (82.6) 2.63″ (66.8) 1/4” NPT 20001 20001X 20001XS-316L 1.00” (25.4) 3.75″ (95.3) 3.00″ (76.2) 1/4” NPT 20002 20002X 20002XS-316L 2.00″ (50.8) 4.75″ (121) 4.00” (102.6) 1/4” NPT 20003 20003X 20003XS-316L 3.00″ (76.2) 5.75″ (146) 5.00″ (127) 1/4” NPT 20004 20004X 20004XS-316L 4.00″ (102.6) 6.75″ (171) 6.00″ (153) 1/4” NPT 20005 20005X 20005XS-316L 5.00″ (127.0) 7.75″ (197) 7.00″ (178) 3/8” NPT 20006 20006X 20006XS-316L 6.00″ (153) 8.75″ (222) 8.00″ (203) 3/8” NPT 20007 20007X 20007XS-316L 7.00″ (178) 9.75″ (248) 9.00″ (229) 3/8” NPT 20009 20009X – 9.00″ (229) 11.75″ (298.5) 11.00″ (279) 4×1/4” NPT 20011 20011X – 11.00″ (279) 13.75″ (349) 13.00″ (330) 4×1/4” NPT - Pricing

-

Aluminum Ring Blade® Air Wipe Systems – up to 150 F (66℃) PART NO. DESCRIPTION SIZE PRICE US DOLLARS 29999 Aluminum Ring Blade Only 3/8" $248.00 20000 Aluminum Ring Blade Only 1/2″ $266.00 20001 Aluminum Ring Blade Only 1″ $282.00 20002 Aluminum Ring Blade Only 2″ $398.00 20003 Aluminum Ring Blade Only 3″ $638.00 20004 Aluminum Ring Blade Only 4″ $892.00 20005 Aluminum Ring Blade Only 5″ $1,172.00 20006 Aluminum Ring Blade Only 6″ $1,475.00 20007 Aluminum Ring Blade Only 7″ $1,850.00 20009 Aluminum Ring Blade Only (Optional hose assemby) * 9″ $2,705.00 20011 Aluminum Ring Blade Only (Optional hose assemby) * 11″ $3,690.00 20009-29002-DA Aluminum Ring Blade Only with c/w Optional Double Hose Assembly 9" $3,155.00 20011-29002-DA Aluminum Ring Blade Only with c/w Optional Double Hose Assembly 11" $4,140.00 * 20009 & 20011 also good for medium temperature range with no hose assembly provided - rubber hose assembly optional and stainless steel assembly is provided for aluminum medium and high stainless steel temperature 9" and 11" models* 21999 Al. Ring Bl. Plus filter with auto drain model 90004 3/8" $373.00 21000 Al. Ring Bl. Plus filter with auto drain model 90004 1/2″ $391.00 21001 Al. Ring Bl. Plus filter with auto drain model 90004 1″ $407.00 21002 Al. Ring Bl. Plus filter with auto drain model 90001 2″ $523.00 21003 Al. Ring Bl. Plus filter with auto drain model 90002 3″ $863.00 21004 Al. Ring Bl. Plus filter with auto drain model 90002 4″ $1,117.00 21005 Al. Ring Bl. Plus filter with auto drain model 90002 5″ $1,397.00 21006 Al. Ring Bl. Plus filter with auto drain model 90002 6″ $1,700.00 21007 Al. Ring Bl. Plus filter with auto drain model 90002 7″ $2,075.00 21009 Al. Ring Bl. Plus filter with auto drain model 90002 (Optional hose assemby) * 9" $2,930.00 21011 Al. Ring Bl. Plus filter with auto drain model 90002 (Optional hose assemby) * 11" $3,915.00 21009-29002-DA Al. Ring Bl. Plus filter with auto drain model 90002 c/w Optional Double Hose Assembly 9" $3,380.00 21011-29002-DA Al. Ring Bl. Plus filter with auto drain model 90002 c/w Optional Double Hose Assembly 11" $4,365.00 22999 Al. Ring Bl. + filter 90004 + regulator with gage model 90008 3/8" $448.00 22000 Al. Ring Bl. + filter 90004 + regulator with gage model 90008 1/2″ $466.00 22001 Al. Ring Bl. + filter 90004 + regulator with gage model 90008 1″ $482.00 22002 Al. Ring Bl. + filter 90001 + regulator with gage model 90008 2″ $598.00 22003 Al. Ring Bl. + filter 90002+ regulator with gage model 90009 3″ $973.00 22004 Al. Ring Bl. + filter 90002 + regulator with gage model 90009 4″ $1,227.00 22005 Al. Ring Bl. + filter 90002 + regulator with gage model 90009 5″ $1,507.00 22006 Al. Ring Bl. + filter 90002 + regulator with gage model 90009 6″ $1,810.00 22007 Al. Ring Bl. + filter 90002 + regulator with gage model 90009 7″ $2,185.00 22009 Al. Ring Bl. + filter 90002 + regulator with gage model 90009 (Optional hose assemby) * 9" $3,040.00 22011 Al. Ring Bl. + filter 90002 + regulator with gage model 90009 (Optional hose assemby) * 11" $4,025.00 22009-29002-DA Al. Ring Bl. + filter 90002 + regulator with gage model 90009 c/w Optional Double Hose Assembly 9" $3,490.00 22011-29002-DA Al. Ring Bl. + filter 90002 + regulator with gage model 90009 c/w Optional Double Hose Assembly 11" $4,475.00 More Information or Buy Here X-Stream Ring Blade® Air Wipe Systems – up to 400 F (204℃) PART NO. DESCRIPTION SIZE PRICE US DOLLARS 29999X X-Stream Ring Blade with stainless hose & shim, brass fittings 3/8" $372.00 20000X X-Stream Ring Blade with stainless hose & shim, brass fittings 1/2″ $395.00 20001X X-Stream Ring Blade with stainless hose & shim, brass fittings 1″ $421.00 20002X X-Stream Ring Blade with stainless hose & shim, brass fittings 2″ $520.00 20003X X-Stream Ring Blade with stainless hose & shim, brass fittings 3″ $850.00 20004X X-Stream Ring Blade with stainless hose & shim, brass fittings 4″ $1,200.00 20005X X-Stream Ring Blade with stainless hose & shim, brass fittings 5″ $1,600.00 20006X X-Stream Ring Blade with stainless hose & shim, brass fittings 6″ $1,900.00 20007X X-Stream Ring Blade with stainless hose & shim, brass fittings 7″ $2,100.00 20009X-29002XS-DA X-Stream Ring Blade with stainless hose & shim, brass fittings (Optional Double SS Hose Assembly) * 9" $3,555.00 20011X-29002XS-DA X-Stream Ring Blade with stainless hose & shim, brass fittings (Optional Double SS Hose Assembly) * 11" $4,540.00 21999X X-Stream Ring Bl. Plus filter with auto drain model 90004 3/8" $497.00 21000X X-Stream Ring Bl. Plus filter with auto drain model 90004 1/2″ $520.00 21001X X-Stream Ring Bl. Plus filter with auto drain model 90004 1″ $546.00 21002X X-Stream Ring Bl. Plus filter with auto drain model 90001 2″ $645.00 21003X X-Stream Ring Bl. Plus filter with auto drain model 90002 3″ $1,075.00 21004X X-Stream Ring Bl. Plus filter with auto drain model 90002 4″ $1,425.00 21005X X-Stream Ring Bl. Plus filter with auto drain model 90002 5″ $1,825.00 21006X X-Stream Ring Bl. Plus filter with auto drain model 90002 6″ $2,125.00 21007X X-Stream Ring Bl. Plus filter with auto drain model 90002 7″ $2,325.00 21009XS-29002XS-DA X-Stream Ring Bl. Plus filter with auto drain model 90002 (Optional Double SS Hose Assembly) * 9" $3,780.00 21011XS-29002XS-DA X-Stream Ring Bl. Plus filter with auto drain model 90002 (Optional Double SS Hose Assembly) * 11" $4,765.00 22999X X-Stream Ring Bl. + filter 90004 + reg. with gage model 90008 3/8" $572.00 22000X X-Stream Ring Bl. + filter 90004 + reg. with gage model 90008 1/2″ $595.00 22001X X-Stream Ring Bl. + filter 90004 + reg. with gage model 90008 1″ $621.00 22002X X-Stream Ring Bl. + filter 90001 + reg. with gage model 90008 2″ $720.00 22003X X-Stream Ring Bl. + filter 90002+ reg. with gage model 90009 3″ $1,185.00 22004X X-Stream Ring Bl. + filter 90002 + reg. with gage model 90009 4″ $1,535.00 22005X X-Stream Ring Bl. + filter 90002 + reg. with gage model 90009 5″ $1,935.00 22006X X-Stream Ring Bl. + filter 90002 + reg. with gage model 90009 6″ $2,235.00 22007X X-Stream Ring Bl. + filter 90002 + reg. with gage model 90009 7″ $2,435.00 22009XS-29002XS-DA X-Stream Ring Bl. + filter 90002 + reg. with gage model 90009 (Optional Double SS Hose Assembly) * 9" $3,890.00 22011XS-29002XS-DA X-Stream Ring Bl. + filter 90002 + reg. with gage model 90009 (Optional Double SS Hose Assembly) * 11" $4,875.00 More Information or Buy Here

Extra Stainless Steel Shims – .002” (.050 mm) for Ring Blade™ Air Wipe Systems PART NO. DESCRIPTION SIZE PRICE US DOLLARS 20999 Stainless Steel Shim – .002″ thick (EACH) 3/8" $14.00 20100 Stainless Steel Shim – .002″ thick (EACH) 1/2" $14.00 20101 Stainless Steel Shim – .002″ thick (EACH) 1" $16.00 20102 Stainless Steel Shim – .002″ thick (EACH) 2" $18.00 20103 Stainless Steel Shim – .002″ thick (EACH) 3" $24.00 20104 Stainless Steel Shim – .002″ thick (EACH) 4" $28.00 20105 Stainless Steel Shim – .002″ thick (EACH) 5" $32.00 20106 Stainless Steel Shim – .002″ thick (EACH) 6" $38.00 20107 Stainless Steel Shim – .002″ thick (EACH) 7" $45.00 20109 Stainless Steel Shim – .002″ thick (EACH) 9" $52.00 20111 Stainless Steel Shim – .002″ thick (EACH) 11" $64.00 20999K Stainless Steel Shim - .002" thick (TWO SHIMS) 3/8" $28.00 20100K Stainless Steel Shim - .002" thick (TWO SHIMS) 1/2" $28.00 20101K Stainless Steel Shim - .002" thick (TWO SHIMS) 1" $32.00 20102K Stainless Steel Shim - .002" thick (TWO SHIMS) 2" $36.00 20103K Stainless Steel Shim - .002" thick (TWO SHIMS) 3" $48.00 20104K Stainless Steel Shim - .002" thick (TWO SHIMS) 4" $56.00 20105K Stainless Steel Shim - .002" thick (TWO SHIMS) 5" $64.00 20106K Stainless Steel Shim - .002" thick (TWO SHIMS) 6" $76.00 20107K Stainless Steel Shim - .002" thick (TWO SHIMS) 7" $90.00 20109K Stainless Steel Shim - .002" thick (TWO SHIMS) 9" $104.00 20111K Stainless Steel Shim - .002" thick (TWO SHIMS) 11" $128.00 More Information or Buy Here

Stainless Steel Ring Blade™ Air Wipe Systems – up to 800 F (427℃) PART NO. DESCRIPTION SIZE PRICE US DOLLARS 29999XS-316L 316l. Stainless Steel Ring Blade with316L stainless hose & shims & fittings 3/8" $840.00 20000XS-316L 316l. Stainless Steel Ring Blade with316L stainless hose & shims & fittings 1/2″ $850.00 20001XS-316L 316l. Stainless Steel Ring Blade with 316L stainless hose & shims & fittings 1″ $950.00 20002XS-316L 316l. Stainless Steel Ring Blade with 316L stainless hose & shims & fittings 2″ $1,250.00 20003XS-316L 316l. Stainless Steel Ring Blade with 316L stainless hose & shims & fittings 3″ $1,825.00 20004XS-316L 316l. Stainless Steel Ring Blade with 316L stainless hose & shims & fittings 4″ $2,525.00 20005XS-316L 316l. Stainless Steel Ring Blade with 316L stainless hose & shims & fittings 5″ $3,250.00 20006XS-316L 316l. Stainless Steel Ring Blade with 316L stainless hose & shims & fittings 6″ $4,290.00 20007XS-316L 316l. Stainless Steel Ring Blade with 316L stainless hose & shims & fittings 7″ $4,450.00 20009XS-316L 316l. Stainless Steel Ring Blade with 316L stainless hose & shims & fittings (Optional SS hose assembly) * 9" $4,800.00 20011XS-316L 316l. Stainless Steel Ring Blade with 316L stainless hose & shims & fittings (Optional SS hose assemby) * 11" $5,200.00 20009XS-29002XS-DA 316l. SSS Ring Blade with316L SS Hose/shims/fittings c/w Optional SS Double Hose Assembly 9" $5,650.00 20011XS-29002XS-DA 316l. SSS Ring Blade with316L SS Hose/shims/fittings c/w Optional SS Double Hose Assembly 11" $6,050.00 21999XS-316L 316l. Stainless Steel Ring Bl. Plus filter with auto drain model 90004 3/8" $965.00 21000XS-316L 316L Stainless Steel Ring Bl. Plus filter with auto drain model 90004 1/2″ $975.00 21001XS-316L 316L Stainless Steel Ring Bl. Plus filter with auto drain model 90004 1″ $1,075.00 21002XS-316L 316L Stainless Steel Ring Bl. Plus filter with auto drain model 90001 2″ $1,375.00 21003XS-316L 316L Stainless Steel Ring Bl. Plus filter with auto drain model 90002 3″ $2,050.00 21004XS-316L 316L Stainless Steel Ring Bl. Plus filter with auto drain model 90002 4″ $2,750.00 21005XS-316L 316L Stainless Steel Ring Bl. Plus filter with auto drain model 90002 5″ $3,475.00 21006XS-316L 316L Stainless Steel Ring Bl. Plus filter with auto drain model 90002 6″ $4,515.00 21007XS-316L 316L Stainless Steel Ring Bl. Plus filter with auto drain model 90002 7″ $4,675.00 21009XS-316L 316L Stainless Steel Ring Bl. Plus filter with auto drain model 90002 (Optional SS hose assemby) * 9" $5,025.00 21011XS-316L 316L Stainless Steel Ring Bl. Plus filter with auto drain model 90002 (Optional SS hose assemby) * 11" $5,425.00 21009XS-29002XS-DA 316L SS Ring Bl. Plus filter with auto drain model 90002 c/w Optional SS Double Hose Assembly 9" $5,875.00 21011XS-29002XS-DA 316L SS Ring Bl. Plus filter with auto drain model 90002 c/w Optional SS Double Hose Assembly 11" $6,275.00 22999XS-316L 316l. SS Ring Bl. + filter 90004 + reg. with gage model 90008 3/8" $1,040.00 22000XS-316L 316L SS Ring Bl. + filter 90004 + reg. with gage model 90008 1/2″ $1,050.00 22001XS-316L 316L SS Ring Bl. + filter 90004 + reg. with gage model 90008 1″ $1,150.00 22002XS-316L 316L SS Ring Bl. + filter 90001 + reg. with gage model 90008 2″ $1,450.00 22003XS-316L 316L SS Ring Bl. + filter 90002 + reg. with gage model 90009 3″ $2,160.00 22004XS-316L 316L SS Ring Bl. + filter 90002 + reg. with gage model 90009 4″ $2,860.00 22005XS-316L 316L SS Ring Bl. + filter 90002 + reg. with gage model 90009 5″ $3,585.00 22006XS-316L 316L SS Ring Bl. + filter 90002 + reg. with gage model 90009 6″ $4,625.00 22007XS-316L 316L SS Ring Bl. + filter 90002 + reg. with gage model 90009 7″ $4,785.00 22009XS-316L 316L SS Ring Bl. + filter 90002 + reg. with gage model 90009 (Optional SS hose assemby) * 9" $5,135.00 22011XS-316L 316L SS Ring Bl. + filter 90002 + reg. with gage model 90009 (Optional SS hose assemby) * 11" $5,535.00 22009XS-29002XS-DA 316L SS Ring Bl. + filter 90002 + reg. with gage model 90009 c/w Optional SS Double Hose Assembly 9" $5,985.00 22011XS-29002XS-DA 316L SS Ring Bl. + filter 90002 + reg, with gage model 90009 c/w Optional SS Double Hose Assembly 11" $6,385.00 More Information or Buy Here Extra 316L Stainless Steel Shims – .002” (.050 mm) for Stainless Ring Blade™ Air Wipe Systems PART NO. DESCRIPTION SIZE PRICE US DOLLARS 20100-316L Stainless Steel Shim - .002" thick (EACH) 1/2" $16.00 20101-316L Stainless Steel Shim - .002" thick (EACH) 1" $18.00 20102-316L Stainless Steel Shim - .002" thick (EACH) 2" $20.00 20103-316L Stainless Steel Shim - .002" thick (EACH) 3" $26.00 20104-316L Stainless Steel Shim - .002" thick (EACH) 4" $30.00 20105-316L Stainless Steel Shim - .002" thick (EACH) 5" $34.00 20106-316L Stainless Steel Shim - .002" thick (EACH) 6" $40.00 20107-316L Stainless Steel Shim - .002" thick (EACH) 7" $44.00 20100-316LK Stainless Steel Shim - .002" thick (EACH) (TWO SHIMS) 1/2" $32.00 20101-316LK Stainless Steel Shim - .002" thick (EACH) (TWO SHIMS) 1" $36.00 20102-316LK Stainless Steel Shim - .002" thick (EACH) (TWO SHIMS) 2" $40.00 20103-316LK Stainless Steel Shim - .002" thick (EACH) (TWO SHIMS) 3" $52.00 20104-316LK Stainless Steel Shim - .002" thick (EACH) (TWO SHIMS) 4" $60.00 20105-316LK Stainless Steel Shim - .002" thick (EACH) (TWO SHIMS) 5" $68.00 20106-316LK Stainless Steel Shim - .002" thick (EACH) (TWO SHIMS) 6" $80.00 20107-316LK Stainless Steel Shim - .002" thick (EACH) (TWO SHIMS) 7" $88.00 More Information or Buy Here

Prices are in US dollars – ex works Cincinnati, OH, USA for orders in USA

Richmond Hill, ON, Canada for international orders.

website : www.nexflow.com

email : sales@nexflow.com

NOTE: Optional hose kit supplied to connect the two halves for the 9″ and 11″