Certain factors are important when considering compressed air for blow-off and cooling applications.

Despite its perceived high energy cost, compressed air is still used extensively for blow-off applications. It can often accomplish the desired task in a simple, compact manner that offsets this energy cost.

However, engineered blow-off products can reduce the energy used by recovering the energy lost as noise and pressure drop by converting it into kinetic energy for blow-off and cooling applications. This energy recovery can be significant.

Noise is one detrimental by-product of using compressed air for blow-off and cooling. But properly engineered blow-offs can significantly reduce compressed air exhaust noise and usually meet OSHA or other international safety standards.

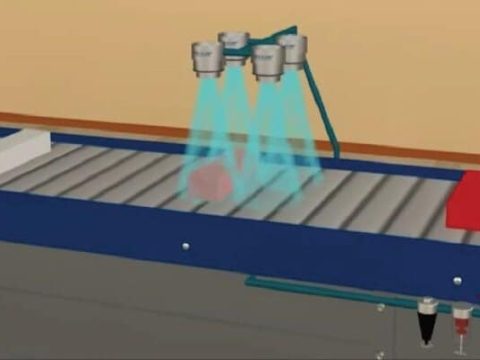

A significant advantage of using engineered blow-off products that recover energy lost by open tubes and jets is the resulting laminar flow of the output air. This creates energy for blow-off and cooling at greater distances from the air discharge point and, therefore, the most flexibility in any cleaning, drying, and cooling application.

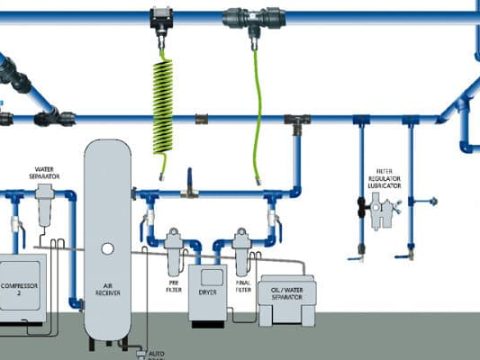

Knowledge about compressed air is generally lacking and it would be wise to read up on the use of compressed air and its care and maintenance. It is also essential to separate fact from fantasy from some claims and use “engineering” sense when they may not make any sense, as explained in the video.

Properly engineered blow-off devices can improve the performance and efficiency of a cleaning, drying, and cooling operation that uses compressed air but understanding how they operate will assist in the choice of the correct product

Nex Flow Air Products Corp. specializes in compressed for blow-off, cooling, and moving applications.

Video url : https://youtu.be/VHhvklvXbj4