This video provides a cost-effective solution to collect and convey dust a long distance without electricity. Portable and simple.

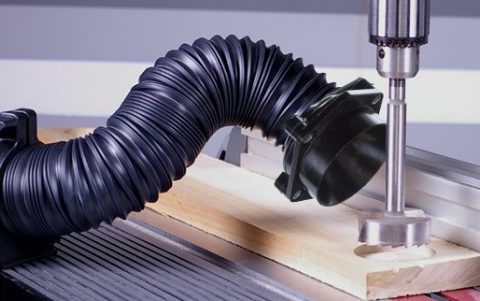

Annual air (flow) amplification products such as Nex Flow Air Amplifiers operate by utilizing the Coanda effect to draw in a large amount of volume at their inlet end by utilizing a small amount of compressed air. When a hose or pipe is attached to the downstream exit of this amplified airflow, whatever fumes, dust, or light particulate is drawn into the inlet can be conveyed through this pipe and tube.

However, back pressure is created to reduce the amplified effect when an attachment is added to an Air Amplifier. In most situations, the actual volume of dust, fumes, or particulate can be conveyed about 10 feet (3 meters) from the inlet to the Air Amplifier is about ten (10) times the compressed air consumption because of this back pressure.

If you want to go longer than this distance, the back pressure increases, and the volume will drop significantly. One way to boost the distance that material can be conveyed is to add an in-line compressed air operated conveyor such as the Nex Flow Ring Vac.

This device is designed specifically for conveying of materials long distances and can extend the distance conveyed up to five times or more depending on the material being conveyed. The Ring vac unit utilizes a venture effect to create a high vacuum at the product entrance allowing it to convey greater distances.

Ring vacs are also used alone for handling heavier solid materials such as plastic resin for hopper loading but when used in conjunction with Air Amplifiers, they overcome the back pressure issues and allow for the transfer of fumes, dust, and particulate which they entrain to much greater distances.

For advice or suggestions on similar applications or any applications of compressed air used for blow-off, cooling, or moving, don’t hesitate to contact me.

Video url : https://youtu.be/CuUenIeTm2M