Industrial cameras, as well as all sorts of sensors, are increasingly used in industrial applications. Many of these are in very hot and humid areas that can also often be difficult to reach, making maintenance difficult. This requires a maintenance-free device to cool, and few options are available.

You cannot use fans because they can be easily clogged and damaged. In addition, you are trying to cool with factory air that can be dirty, corrosive, and otherwise damaging. The temperature in the camera’s area will also be very hot, and fans will simply not work.

Other options are necessary to prevent heat damage to the camera that requires preferably zero or near zero maintenance.

This leaves three options: using pure compressed air to cool, water, or vortex tube technology.

Using pure compressed air to cool can be costly, especially if multiple cameras require cooling. The compressed air will cool, but it may also be warm because it heats up in a hot area. Increasing the volume required to keep the camera cool may be necessary due to the warmer compressed air supply.

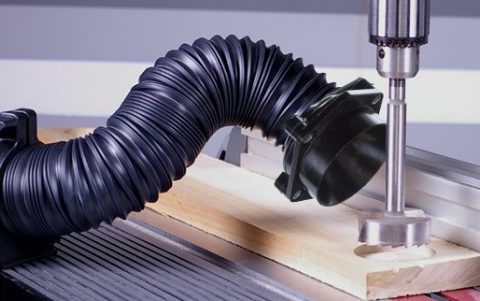

The air would usually be supplied into a camera housing used to protect the camera with holes or some vents to release the compressed air put into the housing.

Using water to cool is a standard option, but it has severe drawbacks. Because the water will be pretty warm, if not hot, after cooling, and the system will be subject to scale deposits forming inside the cooling lines. The water supply lines to the camera are small in diameter, so even a small amount of scale can be an issue where it will not cool very well. Scale can build up on the water supply line and in the camera housing. This requires the removal of the camera to descale properly.

While water may be treated to prevent scale, treatment only slows scale formation. Eventually, cleaning will be required. This results in downtime and added maintenance costs. This is an essential factor as maintenance costs rise over time. However, if the water treatment is perfect and the water itself is very soft, it can still be an option in some cases. But this ideal situation is rare.

Using a vortex tube is a popular method to cool cameras. Even if the compressed air supply is warm, the vortex tube creates a cold stream of air at one end, which would be piped into the camera housing. The vortex tube can be adjusted to compensate for any high compressed air input temperature so that the air supply into the housing provides good cooling.

A vortex tube alone can be used if there is a vent or holes in the housing to vent the cold air after it cools. But if there is no vent, a Panel Cooler can be used, which is self-venting to cool the camera. This is much more energy efficient than just using compressed air alone because you use much less compressed air with a cold air supply.

With the vortex tube, or even with compressed air alone, it is essential that the air supply be clean and dry with an adequate, near-point-of-use filtration system to remove loose moisture and oil if necessary. For camera cooling applications and other critical cooling, a point-of-use low-cost drier should be considered as well.