Product Overview

X-Stream® Ring-Vac® Heavy Duty Pneumatic Conveying System is Available in standard and threaded versions for heavy duty applications. These systems are designed for conveying materials over a longer distance both vertically and horizontally. They move 50% more volume while conveying much further. They are made of hard anodized aluminum to prevent premature wear that could occur with either an ordinary anodized aluminum or Stainless Steel Ring-Vac®.

Many applications require transport over longer distances than is capable with the standard units. The X-Stream® Ring-Vac® Heavy Duty Pneumatic Conveying products have been designed for these rugged and demanding industrial applications.

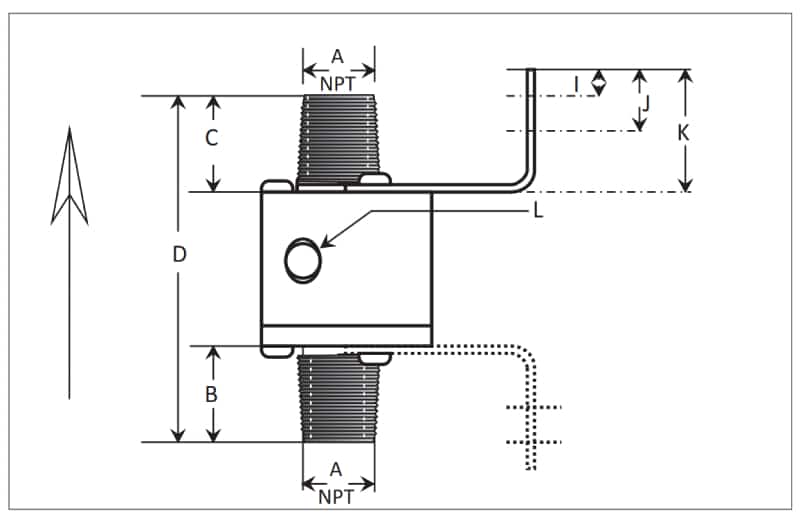

These heavy duty products are available in standard clamp on versions and threaded versions in 1”, 1-1/4”, 1-1/2” and 2” sizes. The threaded units can be threaded into ordinary pipe to make a convenient and powerful system to convey parts, trim, scrap, and other materials. When part wear is a concern, these systems are ideal and low cost.

One application that is ideal for the X-Stream® Ring-Vac® is conveying abrasive or sharp parts such as chips from a machining center. This improves production by removing the chips as they are created in the machining operation, minimizing downtime for cleanup and conveying the scrap into a nearby bin for recycling or disposal.

Because all Ring-Vac® products are compact and lightweight, they are easy to install and portable. Always make sure the compressed air supply is properly filtered to keep the compressed air clean. Water removal filters with automatic drain will keep out moisture. Oil removal filters with automatic drains should be used if there is oil in the air lines.

A regulator installed upstream from the unit will control the pressure into the X-Stream® Ring-Vac® as well as the flow rate and velocity.

When supplying the material to be conveyed, make sure that the container with the material can “breathe”. Atmospheric air needs to be able to pass around the material to be conveyed in order for it to be picked up by the vacuum action. If the material is packed too tightly, the piping that is used to draw in the material can have holes or slots machined into it (smaller than the material conveyed) to create a suction effect to help pick up the material. If the material is still too tightly packed, it needs to be loosened before being conveyed.

The light weight X-Stream® Ring-Vac® can address many of those hard to convey applications for which the standard units may not be strong enough such a heavy trim and heavier materials, or when longer distances need to be conveyed.

Applications

- Hopper loading

- Fiber tensioning

- Material conveying

- Waste/trim removal

- Chip removal

- Part transfer

- Filling operations

Features / Advantages

- Compact

- Quiet

- No moving parts

- Fits standard hose or tube

- Aluminum or stainless steel

- High throughput capability

Videos

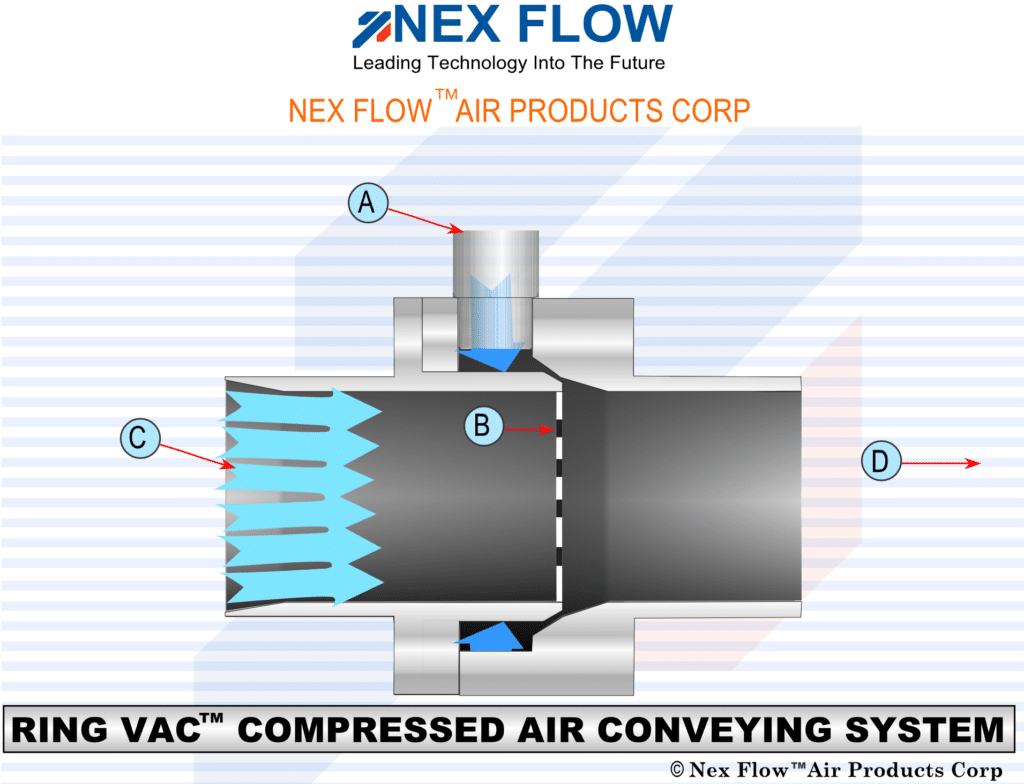

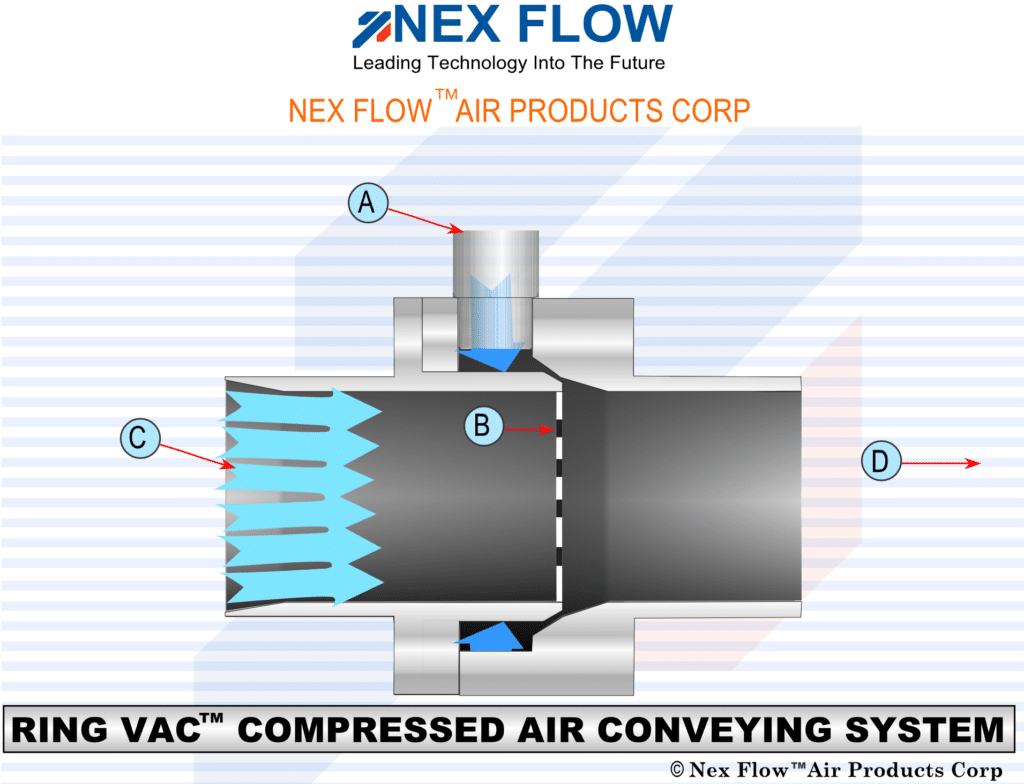

How The Ring Vac® Works

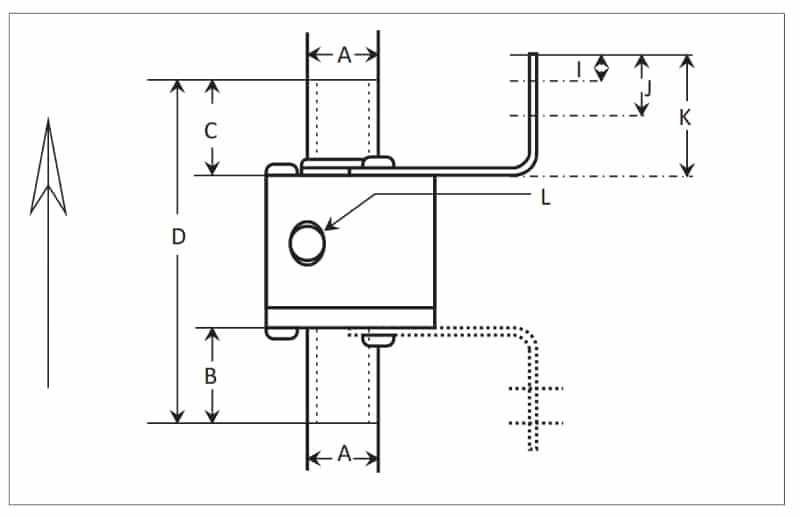

Ring-Vac® compressed air conveying system – Compressed air enters at point (A) into a annular plenum chamber and injected into the throat of the unit though directed nozzles. These jets of compressed air create a vacuum at the inlet (C) which draws in material and accelerates it through the unit and out at (D) conveying the material over a great vertical or horizontal distance.

Specifications

Air Conveyors – Heavy Duty X-Stream® Ring-Vac® Pneumatic Conveying Systems are available in hard anodized aluminum to handle abrasive materials and boosted in performance over standard Ring Vacs to convey over much greater distances both vertically and horizontally.

Special materials can be utilized for unique applications. If greater conveying force is required the conveying “generator” can be machined for higher capacities.

| Outside Diameter (Dimension “A” Hose Diameter) | Model Number | Material of Construction |

|---|---|---|

| 1″ | 30001X | Hard Anodized Aluminum |

| 1-1/4″ | 30002X | Hard Anodized Aluminum |

| 1-1/2″ | 30003X | Hard Anodized Aluminum |

| 2″ | 30004X | Hard Anodized Aluminum |

| 1″ NPT | 30001XT (Threaded) | Hard Anodized Aluminum |

| 1-1/4″ NPT | 30002XT (Threaded) | Hard Anodized Aluminum |

| 1-1/2″ NPT | 30003XT (Threaded) | Hard Anodized Aluminum |

| 2″ NPT | 30004XT (Threaded) | Hard Anodized Aluminum |

NPT Adaptors Available Upon Request

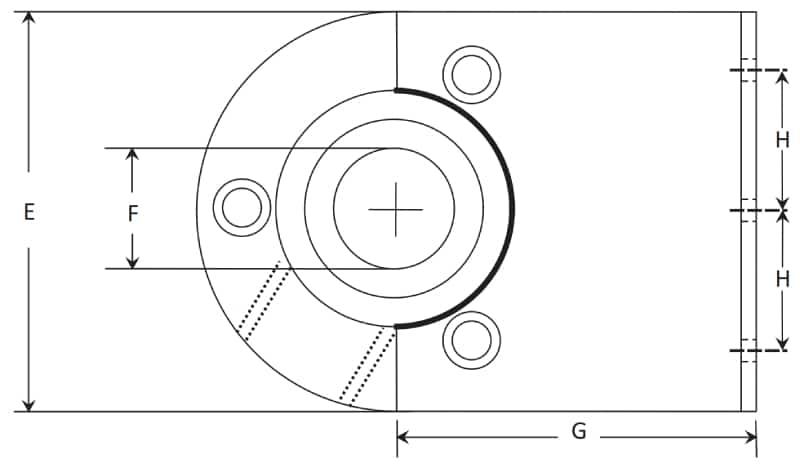

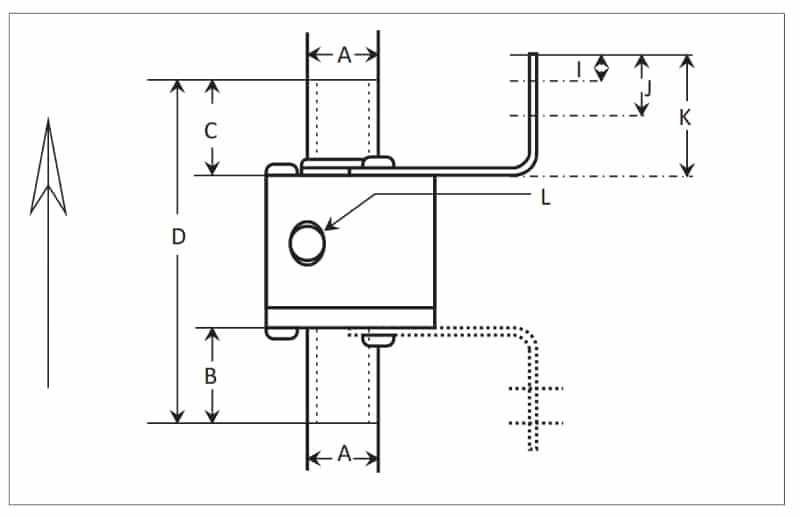

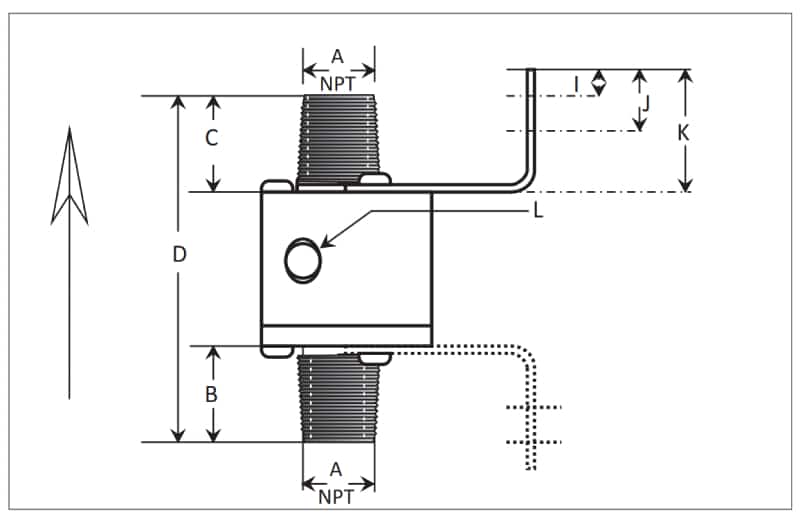

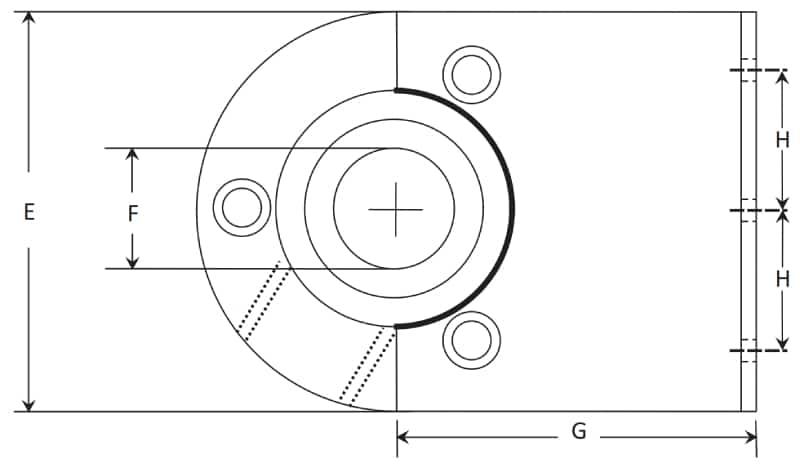

Dimensions

| PART NO. | A IN (MM) | B IN (MM) | C IN (MM) | D IN (MM) | E IN (MM) | F IN (MM) | G IN (MM) | H IN (MM) | I IN (MM) | J IN (MM) | K IN (MM) | L* |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Model 30001X, 30001XT | 1.00” (25.4) | 1.38” (35.1) | 1.5” (38.1) | 4.88” (124.0) | 2.24” (56.8) | 0.75” (19.0) | 2.17” (55.0) | 0.73” (18.5) | 0.39” (10.0) | 1.58” (40) | 1.97” (50.0) | 1/4″ NPT |

| Model 30002X, 30002XT | 1.25” (31.8) | 1.38” (35.1) | 1.5” (38.1) | 4.88” (124.0) | 2.49” (63.2) | 1.00” (25.4) | 2.21” (56.3) | 0.73” (18.5) | 0.39” (10.0) | 1.77” (45) | 2.17” (55.0) | 1/4″ NPT |

| Model 30003X, 30003XT | 1.5” (38.1) | 1.38” (35.1) | 1.5” (38.1) | 4.88” (124.0) | 2.75” (69.9) | 1.125” (28.6) | 2.15” (54.5) | 0.89” (22.5) | 0.39” (10.0) | 1.58” (40) | 1.97” (50.0) | 3/8” NPT |

| Model 30004X, 30004XT | 2.00” (50.8) | 1.38” (35.1) | 1.5” (38.1) | 4.88” (124.0) | 3.21” (81.6) | 1.75” (44.5) | 2.39” (60.7) | 1.18” (30) | 0.39” (10.0) | 1.58” (40) | 1.97” (50.0) | 3/8” NPT |

* BSP adaptors supplied upon request free of charge.

Top View

Series 30001X – 30004X

Series 30001XT Threaded Series 30001XT

Performance

| MODEL | Size Outside Diameter inches (mm) | Air Consumption SCFM at 80 PSIG (SLPM at 5.5 BAR) | Vacuum inches H2O (KPA) |

|---|---|---|---|

| 30001X / 30001XT | 1″ (25mm) | 21(595) | -60 (-15) |

| 30002X / 30002XT | 1 1/4 ” (32mm) | 33 (934) | -55 (-14) |

| 30003X / 30003XT | 1-1/2″ (38mm) | 44 (1245) | -50 (-13) |

| 30004X / 30004XT | 2″ (51mm) | 58 (1642) | -36 (-9) |

| Hard Anodized Aluminum X-Stream™ Ring Vac™ | |||

|---|---|---|---|

| PART NO. | DESCRIPTION | SIZE | PRICE US DOLLARS |

| 30001X | Aluminum Ring-Vac Only | 1″ | $298.00 |

| 30002X | Aluminum Ring-Vac Only | 1-1/4″ | $328.00 |

| 30003X | Aluminum Ring-Vac Only | 1-1/2″ | $405.00 |

| 30004X | Aluminum Ring-Vac Only | 2″ | $486.00 |

| 31001X | Aluminum Ring-Vac plus Filter with Auto Drain Model 90004 | 1″ | $423.00 |

| 31002X | Aluminum Ring-Vac plus Filter with Auto Drain Model 90004 | 1-14″ | $453.00 |

| 31003X | Aluminum Ring-Vac plus Filter with Auto Drain Model 90001 | 1-1/2″ | $530.00 |

| 31004X | Aluminum Ring-Vac plus Filter with Auto Drain Model 90001 | 2″ | $611.00 |

| 32001X | Aluminum Ring-Vac + filter 90004 + reg. with gage model 90008 | 1″ | $498.00 |

| 32002X | Aluminum Ring-Vac + filter 90004 + reg. with gage model 90008 | 1-14″ | $528.00 |

| 32003X | Aluminum Ring-Vac + filter 90001 + reg. with gage model 90008 | 1-1/2″ | $605.00 |

| 32004X | Aluminum Ring-Vac + filter 90001 + reg. with gage model 90009 | 2″ | $721.00 |

| 30001XT | Threaded Aluminum Ring-Vac Only | 1″ | $385.00 |

| 30002XT | Threaded Aluminum Ring-Vac Only | 1-1/4″ | $425.00 |

| 30003XT | Threaded Aluminum Ring-Vac Only | 1-1/2″ | $510.00 |

| 30004XT | Threaded Aluminum Ring-Vac Only | 2″ | $580.00 |

| 31001XT | Threaded Al. Ring-Vac plus Filter with Auto Drain Model 90004 | 1″ | $510.00 |

| 31002XT | Threaded Al. Ring-Vac plus Filter with Auto Drain Model 90004 | 1-14″ | $550.00 |

| 31003XT | Threaded Al. Ring-Vac plus Filter with Auto Drain Model 90001 | 1-1/2″ | $635.00 |

| 31004XT | Threaded Al. Ring-Vac plus Filter with Auto Drain Model 90001 | 2″ | $705.00 |

| 32001XT | Thr. Al. Ring-Vac + filter 90004 + reg. with gage model 90008 | 1″ | $585.00 |

| 32002XT | Thr. Al. Ring-Vac + filter 90004 + reg. with gage model 90008 | 1-14″ | $625.00 |

| 32003XT | Thr. Al. Ring-Vac + filter 90001 + reg. with gage model 90008 | 1-1/2″ | $710.00 |

| 32004XT | Thr. Al. Ring-Vac + filter 90001 + reg. with gage model 90009 | 2″ | $815.00 |

| More Information or Buy Here |

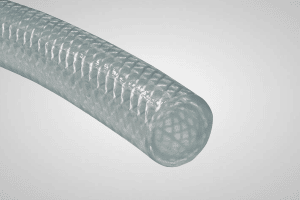

| Hose for Air Operated Conveyor | |||

|---|---|---|---|

| PART NO. | DESCRIPTION | SIZE | PRICE US DOLLARS |

| 39999H10 | 10 foot clear reinforced PVC for Standard Ring Vacs - 1/2" | 1/2" | $41.00 |

| 39999H20 | 20 foot clear reinforced PVC for Standard Ring Vacs - 1/2" | 1/2" | $70.00 |

| 39999H30 | 30 foot clear reinforced PVC for Standard Ring Vacs - 1/2" | 1/2" | $100.00 |

| 39999H40 | 40 foot clear reinforced PVC for Standard Ring Vacs - 1/2" | 1/2" | $126.00 |

| 39999H50 | 50 foot clear reinforced PVC for Standard Ring Vacs - 1/2" | 1/2" | $151.00 |

| 30000H10 | 10 foot clear reinforced PVC for Standard Ring Vacs - 3/4" | 3/4" | $57.00 |

| 30000H20 | 20 foot clear reinforced PVC for Standard Ring Vacs - 3/4' | 3/4" | $89.00 |

| 30000H30 | 30 foot clear reinforced PVC for Standard Ring Vacs - 3/4" | 3/4" | $123.00 |

| 30000H40 | 40 foot clear reinforced PVC for Standard Ring Vacs - 3/4" | 3/4" | $156.00 |

| 30000H50 | 50 foot clear reinforced PVC for Standard Ring Vacs - 3/4" | 3/4" | $186.00 |

| 30001H10 | 10 foot clear reinforced PVC for Standard Ring Vacs - 1" | 1" | $63.00 |

| 30001H20 | 20 foot clear reinforced PVC for Standard Ring Vacs - 1" | 1" | $100.00 |

| 30001H30 | 30 foot clear reinforced PVC for Standard Ring Vacs - 1" | 1" | $138.00 |

| 30001H40 | 40 foot clear reinforced PVC for Standard Ring Vacs - 1" | 1" | $174.00 |

| 30001H50 | 50 foot clear reinforced PVC for Standard Ring Vacs - 1" | 1" | $216.00 |

| 30002H10 | 10 foot clear reinforced PVC for Standard Ring Vacs - 1-1/4" | 1-1/4" | $67.00 |

| 30002H20 | 20 foot clear reinforced PVC for Standard Ring Vacs - 1-1/4" | 1-1/4" | $109.00 |

| 30002H30 | 30 foot clear reinforced PVC for Standard Ring Vacs - 1-1/4" | 1-1/4" | $155.00 |

| 30002H40 | 40 foot clear reinforced PVC for Standard Ring Vacs - 1-1/4" | 1-1/4" | $196.00 |

| 30002H50 | 50 foot clear reinforced PVC for Standard Ring Vacs - 1-1/4" | 1-1/4" | $234.00 |

| 30003H10 | 10 foot clear reinforced PVC for Standard Ring Vacs - 1-1/2" | 1-1/2" | $84.00 |

| 30003H20 | 20 foot clear reinforced PVC for Standard Ring Vacs - 1-1/2" | 1-1/2" | $146.00 |

| 30003H30 | 30 foot clear reinforced PVC for Standard Ring Vacs - 1-1/2" | 1-1/2" | $197.00 |

| 30003H40 | 40 foot clear reinforced PVC for Standard Ring Vacs - 1-1/2" | 1-1/2" | $257.00 |

| 30003H50 | 50 foot clear reinforced PVC for Standard Ring Vacs - 1-1/2" | 1-1/2" | $314.00 |

| 30004H10 | 10 foot clear reinforced PVC for Standard Ring Vacs - 2" | 2" | $107.00 |

| 30004H20 | 20 foot clear reinforced PVC for Standard Ring Vacs - 2" | 2" | $192.00 |

| 30004H30 | 30 foot clear reinforced PVC for Standard Ring Vacs - 2" | 2" | $273.00 |

| 30004H40 | 40 foot clear reinforced PVC for Standard Ring Vacs - 2" | 2" | $357.00 |

| 30004H50 | 50 foot clear reinforced PVC for Standard Ring Vacs - 2" | 2" | $441.00 |

| More Information or Buy Here |

| Hose Clamps For Ring Vac Hose | |||

|---|---|---|---|

| PART NO. | DESCRIPTION | SIZE | PRICE US DOLLARS |

| 39999CLMP | Hose clamp for 1/2" hose - 304 stainless | 9/16" inch to 1" | $5.00 |

| 30000CLMP | Hose clamp for 3/4" hose - 304 stainless | 11/16" inch to 1-1/4" | $5.20 |

| 30001CLMP | Hose clamp for 1" hose - 304 stainless | 13/16" inch to 1-1/2" | $4.30 |

| 30002CLMP | Hose clamp for 1-1/4" hose - 304 stainless | 13/16" inch to 1-3/4" | $5.50 |

| 30003CLMP | Hose clamp for 1-1/2" hose - 304 stainless | 1-1/16" inch to 2" | $5.70 |

| 30004CLMP | Hose clamp for 2" hose - 304 stainless | 1-9/16" inch to 2-1/2" | $6.00 |

| More Information or Buy Here |

- Overview

-

Product Overview

X-Stream® Ring-Vac® Heavy Duty Pneumatic Conveying System is Available in standard and threaded versions for heavy duty applications. These systems are designed for conveying materials over a longer distance both vertically and horizontally. They move 50% more volume while conveying much further. They are made of hard anodized aluminum to prevent premature wear that could occur with either an ordinary anodized aluminum or Stainless Steel Ring-Vac®.

Many applications require transport over longer distances than is capable with the standard units. The X-Stream® Ring-Vac® Heavy Duty Pneumatic Conveying products have been designed for these rugged and demanding industrial applications.

These heavy duty products are available in standard clamp on versions and threaded versions in 1”, 1-1/4”, 1-1/2” and 2” sizes. The threaded units can be threaded into ordinary pipe to make a convenient and powerful system to convey parts, trim, scrap, and other materials. When part wear is a concern, these systems are ideal and low cost.

One application that is ideal for the X-Stream® Ring-Vac® is conveying abrasive or sharp parts such as chips from a machining center. This improves production by removing the chips as they are created in the machining operation, minimizing downtime for cleanup and conveying the scrap into a nearby bin for recycling or disposal.

Because all Ring-Vac® products are compact and lightweight, they are easy to install and portable. Always make sure the compressed air supply is properly filtered to keep the compressed air clean. Water removal filters with automatic drain will keep out moisture. Oil removal filters with automatic drains should be used if there is oil in the air lines.

A regulator installed upstream from the unit will control the pressure into the X-Stream® Ring-Vac® as well as the flow rate and velocity.

When supplying the material to be conveyed, make sure that the container with the material can “breathe”. Atmospheric air needs to be able to pass around the material to be conveyed in order for it to be picked up by the vacuum action. If the material is packed too tightly, the piping that is used to draw in the material can have holes or slots machined into it (smaller than the material conveyed) to create a suction effect to help pick up the material. If the material is still too tightly packed, it needs to be loosened before being conveyed.

The light weight X-Stream® Ring-Vac® can address many of those hard to convey applications for which the standard units may not be strong enough such a heavy trim and heavier materials, or when longer distances need to be conveyed.

Applications

- Hopper loading

- Fiber tensioning

- Material conveying

- Waste/trim removal

- Chip removal

- Part transfer

- Filling operations

- Advantages

-

Features / Advantages

- Compact

- Quiet

- No moving parts

- Fits standard hose or tube

- Aluminum or stainless steel

- High throughput capability

- Videos

-

Videos

How The Ring Vac® Works

Ring-Vac® compressed air conveying system – Compressed air enters at point (A) into a annular plenum chamber and injected into the throat of the unit though directed nozzles. These jets of compressed air create a vacuum at the inlet (C) which draws in material and accelerates it through the unit and out at (D) conveying the material over a great vertical or horizontal distance.

- Specs

-

Specifications

Air Conveyors – Heavy Duty X-Stream® Ring-Vac® Pneumatic Conveying Systems are available in hard anodized aluminum to handle abrasive materials and boosted in performance over standard Ring Vacs to convey over much greater distances both vertically and horizontally.

Special materials can be utilized for unique applications. If greater conveying force is required the conveying “generator” can be machined for higher capacities.Outside Diameter (Dimension “A” Hose Diameter) Model Number Material of Construction 1″ 30001X Hard Anodized Aluminum 1-1/4″ 30002X Hard Anodized Aluminum 1-1/2″ 30003X Hard Anodized Aluminum 2″ 30004X Hard Anodized Aluminum 1″ NPT 30001XT (Threaded) Hard Anodized Aluminum 1-1/4″ NPT 30002XT (Threaded) Hard Anodized Aluminum 1-1/2″ NPT 30003XT (Threaded) Hard Anodized Aluminum 2″ NPT 30004XT (Threaded) Hard Anodized Aluminum NPT Adaptors Available Upon Request

- Dimensions

-

Dimensions

PART NO. A IN (MM) B IN (MM) C IN (MM) D IN (MM) E IN (MM) F IN (MM) G IN (MM) H IN (MM) I IN (MM) J IN (MM) K IN (MM) L* Model 30001X, 30001XT 1.00” (25.4) 1.38” (35.1) 1.5” (38.1) 4.88” (124.0) 2.24” (56.8) 0.75” (19.0) 2.17” (55.0) 0.73” (18.5) 0.39” (10.0) 1.58” (40) 1.97” (50.0) 1/4″ NPT Model 30002X, 30002XT 1.25” (31.8) 1.38” (35.1) 1.5” (38.1) 4.88” (124.0) 2.49” (63.2) 1.00” (25.4) 2.21” (56.3) 0.73” (18.5) 0.39” (10.0) 1.77” (45) 2.17” (55.0) 1/4″ NPT Model 30003X, 30003XT 1.5” (38.1) 1.38” (35.1) 1.5” (38.1) 4.88” (124.0) 2.75” (69.9) 1.125” (28.6) 2.15” (54.5) 0.89” (22.5) 0.39” (10.0) 1.58” (40) 1.97” (50.0) 3/8” NPT Model 30004X, 30004XT 2.00” (50.8) 1.38” (35.1) 1.5” (38.1) 4.88” (124.0) 3.21” (81.6) 1.75” (44.5) 2.39” (60.7) 1.18” (30) 0.39” (10.0) 1.58” (40) 1.97” (50.0) 3/8” NPT * BSP adaptors supplied upon request free of charge.

Top View

Series 30001X – 30004X

Series 30001XT Threaded Series 30001XT

- Performance

-

Performance

MODEL Size Outside Diameter inches (mm) Air Consumption SCFM at 80 PSIG (SLPM at 5.5 BAR) Vacuum inches H2O (KPA) 30001X / 30001XT 1″ (25mm) 21(595) -60 (-15) 30002X / 30002XT 1 1/4 ” (32mm) 33 (934) -55 (-14) 30003X / 30003XT 1-1/2″ (38mm) 44 (1245) -50 (-13) 30004X / 30004XT 2″ (51mm) 58 (1642) -36 (-9) - Pricing

-

Hard Anodized Aluminum X-Stream™ Ring Vac™ PART NO. DESCRIPTION SIZE PRICE US DOLLARS 30001X Aluminum Ring-Vac Only 1″ $298.00 30002X Aluminum Ring-Vac Only 1-1/4″ $328.00 30003X Aluminum Ring-Vac Only 1-1/2″ $405.00 30004X Aluminum Ring-Vac Only 2″ $486.00 31001X Aluminum Ring-Vac plus Filter with Auto Drain Model 90004 1″ $423.00 31002X Aluminum Ring-Vac plus Filter with Auto Drain Model 90004 1-14″ $453.00 31003X Aluminum Ring-Vac plus Filter with Auto Drain Model 90001 1-1/2″ $530.00 31004X Aluminum Ring-Vac plus Filter with Auto Drain Model 90001 2″ $611.00 32001X Aluminum Ring-Vac + filter 90004 + reg. with gage model 90008 1″ $498.00 32002X Aluminum Ring-Vac + filter 90004 + reg. with gage model 90008 1-14″ $528.00 32003X Aluminum Ring-Vac + filter 90001 + reg. with gage model 90008 1-1/2″ $605.00 32004X Aluminum Ring-Vac + filter 90001 + reg. with gage model 90009 2″ $721.00 30001XT Threaded Aluminum Ring-Vac Only 1″ $385.00 30002XT Threaded Aluminum Ring-Vac Only 1-1/4″ $425.00 30003XT Threaded Aluminum Ring-Vac Only 1-1/2″ $510.00 30004XT Threaded Aluminum Ring-Vac Only 2″ $580.00 31001XT Threaded Al. Ring-Vac plus Filter with Auto Drain Model 90004 1″ $510.00 31002XT Threaded Al. Ring-Vac plus Filter with Auto Drain Model 90004 1-14″ $550.00 31003XT Threaded Al. Ring-Vac plus Filter with Auto Drain Model 90001 1-1/2″ $635.00 31004XT Threaded Al. Ring-Vac plus Filter with Auto Drain Model 90001 2″ $705.00 32001XT Thr. Al. Ring-Vac + filter 90004 + reg. with gage model 90008 1″ $585.00 32002XT Thr. Al. Ring-Vac + filter 90004 + reg. with gage model 90008 1-14″ $625.00 32003XT Thr. Al. Ring-Vac + filter 90001 + reg. with gage model 90008 1-1/2″ $710.00 32004XT Thr. Al. Ring-Vac + filter 90001 + reg. with gage model 90009 2″ $815.00 More Information or Buy Here Hose for Air Operated Conveyor PART NO. DESCRIPTION SIZE PRICE US DOLLARS 39999H10 10 foot clear reinforced PVC for Standard Ring Vacs - 1/2" 1/2" $41.00 39999H20 20 foot clear reinforced PVC for Standard Ring Vacs - 1/2" 1/2" $70.00 39999H30 30 foot clear reinforced PVC for Standard Ring Vacs - 1/2" 1/2" $100.00 39999H40 40 foot clear reinforced PVC for Standard Ring Vacs - 1/2" 1/2" $126.00 39999H50 50 foot clear reinforced PVC for Standard Ring Vacs - 1/2" 1/2" $151.00 30000H10 10 foot clear reinforced PVC for Standard Ring Vacs - 3/4" 3/4" $57.00 30000H20 20 foot clear reinforced PVC for Standard Ring Vacs - 3/4' 3/4" $89.00 30000H30 30 foot clear reinforced PVC for Standard Ring Vacs - 3/4" 3/4" $123.00 30000H40 40 foot clear reinforced PVC for Standard Ring Vacs - 3/4" 3/4" $156.00 30000H50 50 foot clear reinforced PVC for Standard Ring Vacs - 3/4" 3/4" $186.00 30001H10 10 foot clear reinforced PVC for Standard Ring Vacs - 1" 1" $63.00 30001H20 20 foot clear reinforced PVC for Standard Ring Vacs - 1" 1" $100.00 30001H30 30 foot clear reinforced PVC for Standard Ring Vacs - 1" 1" $138.00 30001H40 40 foot clear reinforced PVC for Standard Ring Vacs - 1" 1" $174.00 30001H50 50 foot clear reinforced PVC for Standard Ring Vacs - 1" 1" $216.00 30002H10 10 foot clear reinforced PVC for Standard Ring Vacs - 1-1/4" 1-1/4" $67.00 30002H20 20 foot clear reinforced PVC for Standard Ring Vacs - 1-1/4" 1-1/4" $109.00 30002H30 30 foot clear reinforced PVC for Standard Ring Vacs - 1-1/4" 1-1/4" $155.00 30002H40 40 foot clear reinforced PVC for Standard Ring Vacs - 1-1/4" 1-1/4" $196.00 30002H50 50 foot clear reinforced PVC for Standard Ring Vacs - 1-1/4" 1-1/4" $234.00 30003H10 10 foot clear reinforced PVC for Standard Ring Vacs - 1-1/2" 1-1/2" $84.00 30003H20 20 foot clear reinforced PVC for Standard Ring Vacs - 1-1/2" 1-1/2" $146.00 30003H30 30 foot clear reinforced PVC for Standard Ring Vacs - 1-1/2" 1-1/2" $197.00 30003H40 40 foot clear reinforced PVC for Standard Ring Vacs - 1-1/2" 1-1/2" $257.00 30003H50 50 foot clear reinforced PVC for Standard Ring Vacs - 1-1/2" 1-1/2" $314.00 30004H10 10 foot clear reinforced PVC for Standard Ring Vacs - 2" 2" $107.00 30004H20 20 foot clear reinforced PVC for Standard Ring Vacs - 2" 2" $192.00 30004H30 30 foot clear reinforced PVC for Standard Ring Vacs - 2" 2" $273.00 30004H40 40 foot clear reinforced PVC for Standard Ring Vacs - 2" 2" $357.00 30004H50 50 foot clear reinforced PVC for Standard Ring Vacs - 2" 2" $441.00 More Information or Buy Here Hose Clamps For Ring Vac Hose PART NO. DESCRIPTION SIZE PRICE US DOLLARS 39999CLMP Hose clamp for 1/2" hose - 304 stainless 9/16" inch to 1" $5.00 30000CLMP Hose clamp for 3/4" hose - 304 stainless 11/16" inch to 1-1/4" $5.20 30001CLMP Hose clamp for 1" hose - 304 stainless 13/16" inch to 1-1/2" $4.30 30002CLMP Hose clamp for 1-1/4" hose - 304 stainless 13/16" inch to 1-3/4" $5.50 30003CLMP Hose clamp for 1-1/2" hose - 304 stainless 1-1/16" inch to 2" $5.70 30004CLMP Hose clamp for 2" hose - 304 stainless 1-9/16" inch to 2-1/2" $6.00 More Information or Buy Here