Product Overview

316L Stainless Steel Ring Vac with Sanitary FlangeThe Nex Flow® Ring-Vac® Pneumatic Conveying System with Sanitary Flanges are made especially for food, pharmaceutical, and other sanitary applications. All units are made from 316L stainless in sizes of 1″ to 3″.

Many applications in a sanitary environment require transport of materials over long distances. The Ring-Vac® with Sanitary Flanges have been designed for these special and demanding applications.

All Ring-Vac® products are compact,lightweight, easy to install, and portable. The compressed air supply in sanitary environments must be properly filtered to keep the compressed air clean and dry. Special filtration products are available from other supplies for this purpose if necessary.

A regulator installed upstream from the unit will control the pressure supplied to the Ring-Vac® and allow for the variation in flow rate and velocity.

Material to be conveyed must be able to have some air movement around the material to draw it into the Ring-Vac® system. It has to “breathe” so that the air passes around the material to be conveyed in order for it to be picked up. Another option is to drill holes or slots into the piping (smaller than the material conveyed) to create a suction to help pick up the material. If the material is too packed together, it may need to be loosened before it can be properly picked up to be conveyed.

Applications

- Hopper loading

- Fiber tensioning

- Material conveying

- Waste/trim removal

- Chip removal

- Part transfer

- Filling operations

Features / Advantages

316L Stainless Steel Ring Vac with Sanitary Flange

- Compact

- Quiet

- No moving parts

- Fits standard hose or tube

- Aluminum or stainless steel

- High throughput capability

Videos

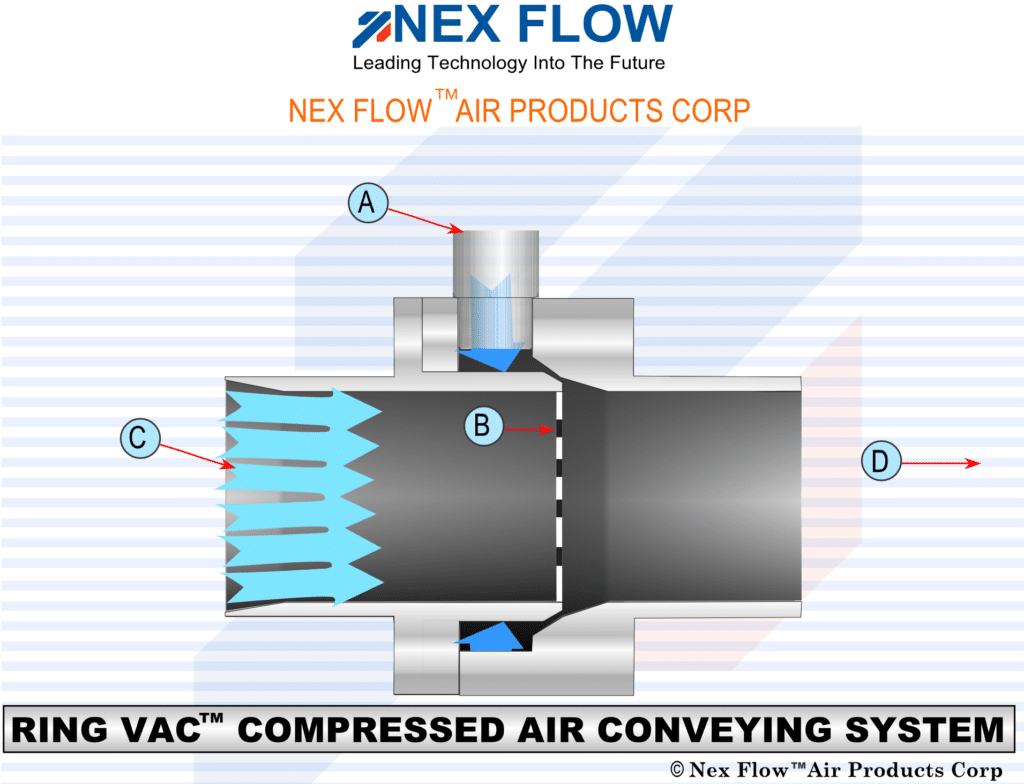

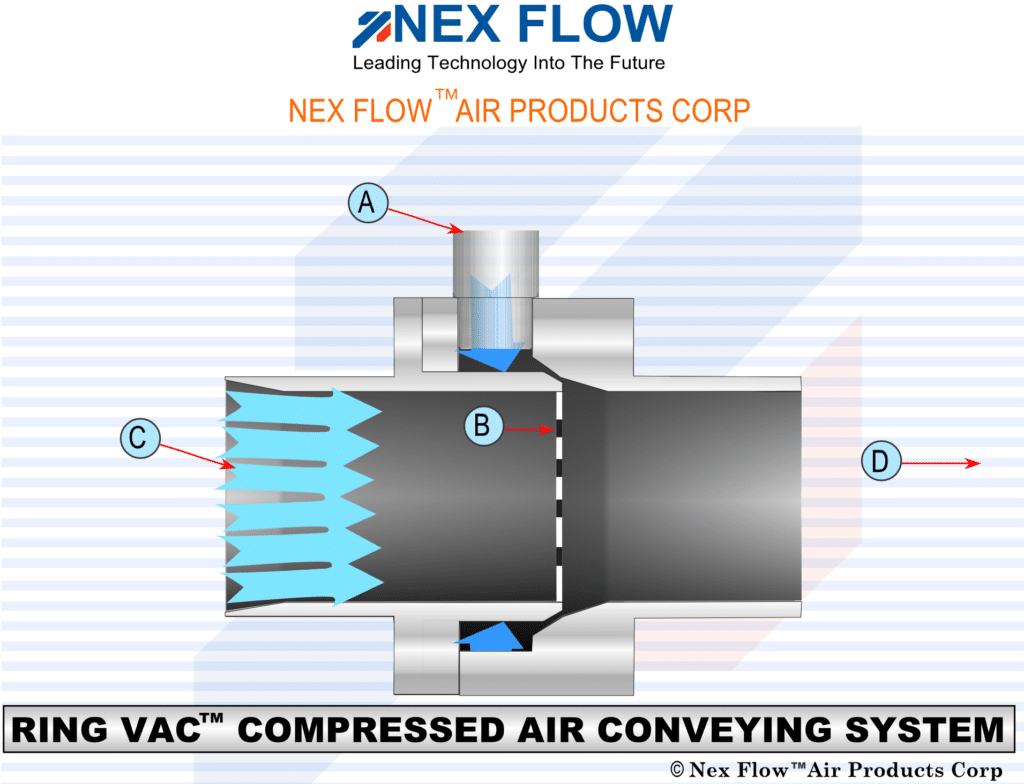

How The Ring Vac® Works

Ring-Vac® compressed air conveying system – Compressed air enters at point (A) into a annular plenum chamber and injected into the throat of the unit though directed nozzles. These jets of compressed air create a vacuum at the inlet (C) which draws in material and accelerates it through the unit and out at (D) conveying the material over a great vertical or horizontal distance.

Specifications

| PART NO. | DESCRIPTION | Size |

|---|---|---|

| 30003S-316L-SAN | 316L Stainless Steel Ring-Vac Only with Sanitary Flange | 1-1/2″ |

| 30004S-316L-SAN | 316L Stainless Steel Ring-Vac Only with Sanitary Flange | 2″ |

| 30005S-316L-SAN | 316L Stainless Steel Ring-Vac Only with Sanitary Flange | 2-1/2″ |

| 30006S-316L-SAN | 316L Stainless Steel Ring-Vac Only with Sanitary Flange | 3″ |

| PART NO. | DESCRIPTION | Size |

|---|---|---|

| 30003HTS-316L-SAN | 316L Stainless Steel Ring-Vac High temp. Only with Sanitary Flange | 1-1/2″ |

| 30004HTS-316L-SAN | 316L Stainless Steel Ring-Vac High temp. Only with Sanitary Flange | 2″ |

| 30005HTS-316L-SAN | 316L Stainless Steel Ring-Vac High temp. Only with Sanitary Flange | 2-1/2″ |

| 30006HTS-316L-SAN | 316L Stainless Steel Ring-Vac High temp. Only with Sanitary Flange | 3″ |

Performance

| MODEL | Size Outside Diameter inches (mm) | Air Consumption SCFM at 80 PSIG (SLPM at 5.5 BAR) | Vacuum inches H2O (KPG) |

|---|---|---|---|

| 30000 30000S 30000HTS 30000S-316L 30000HTS-316L | 3/4″ (19mm) | 11 (303) | -72 (-18) |

| 30001 30001S 30001T 30001TS 30001HTS 30001THTS 30001S-316L 30001HST-316L | 1″ (25mm) | 15 (415) | -42 (-11) |

| 30002 30002S 30002T 30002TS 30002SHTS 30002HTS 30002S-316L 30002HTS-316L | 1 1/4 ” (32mm) | 26 (730) | -42 (-11) |

| 30003TS 30003THTS 30003THTS 30003THTS 30003S-316L 30003HTS-316L 30003S-316L-SAN 30003HTS-316L-SAN | 1-1/2″ (38mm) | 33 (932) | -39 (-9) |

| 30004 30004S 30004T 30004TS 30004THTS 30004HTS 30004S-316L 30004HTS-316L 30004S-316L-SAN 30004HTS-316L-SAN | 2″ (51mm) | 45 (1270) | -28 (-7) |

| 30005 30005S 30005HTS 30005S-316L-SAN 30005HTS-316L-SAN | 2 1/2″ (63.5mm) | 58.5 (1655) | -23.5 (-6) |

| 30006 30006S 30006HTS 30006TS 30006THTS 30006S-316L-SAN 30006HTS-316L-SAN | 3″ (76mm) | 69 (1940) | -14.7 (-4) |

| 316L Stainless Steel Ring Vac™ only with Sanitary Flange | |||

|---|---|---|---|

| PART NO. | DESCRIPTION | SIZE | PRICE US DOLLARS |

| 30003S-316L-SAN | 316L Stainless Steel Ring-Vac Only with Sanitary Flange | 1-1/2″ | $1,200.00 |

| 30004S-316L-SAN | 316L Stainless Steel Ring-Vac Only with Sanitary Flange | 2″ | $1,300.00 |

| 30005S-316L-SAN | 316L Stainless Steel Ring-Vac Only with Sanitary Flange | 2-1/2″ | $2,100.00 |

| 30006S-316L-SAN | 316L Stainless Steel Ring-Vac Only with Sanitary Flange | 3″ | $3,300.00 |

| More Information or Buy Here |

| 316L Stainless Steel Ring Vac™ High temp. Only with Sanitary Flange | |||

|---|---|---|---|

| PART NO. | DESCRIPTION | SIZE | PRICE US DOLLARS |

| 30003HTS-316L-SAN | 316L Stainless Steel Ring-Vac High temp. Only with Sanitary Flange | 1-1/2″ | $1,400.00 |

| 30004HTS-316L-SAN | 316L Stainless Steel Ring-Vac High temp. Only with Sanitary Flange | 2″ | $1,500.00 |

| 30005HTS-316L-SAN | 316L Stainless Steel Ring-Vac High temp. Only with Sanitary Flange | 2-1/2″ | $2,300.00 |

| 30006HTS-316L-SAN | 316L Stainless Steel Ring-Vac High temp. Only with Sanitary Flange | 3″ | $3,600.00 |

| More Information or Buy Here |

| Hose for Air Operated Conveyor | |||

|---|---|---|---|

| PART NO. | DESCRIPTION | SIZE | PRICE US DOLLARS |

| 39999H10 | 10 foot clear reinforced PVC for Standard Ring Vacs - 1/2" | 1/2" | $41.00 |

| 39999H20 | 20 foot clear reinforced PVC for Standard Ring Vacs - 1/2" | 1/2" | $70.00 |

| 39999H30 | 30 foot clear reinforced PVC for Standard Ring Vacs - 1/2" | 1/2" | $100.00 |

| 39999H40 | 40 foot clear reinforced PVC for Standard Ring Vacs - 1/2" | 1/2" | $126.00 |

| 39999H50 | 50 foot clear reinforced PVC for Standard Ring Vacs - 1/2" | 1/2" | $151.00 |

| 30000H10 | 10 foot clear reinforced PVC for Standard Ring Vacs - 3/4" | 3/4" | $57.00 |

| 30000H20 | 20 foot clear reinforced PVC for Standard Ring Vacs - 3/4' | 3/4" | $89.00 |

| 30000H30 | 30 foot clear reinforced PVC for Standard Ring Vacs - 3/4" | 3/4" | $123.00 |

| 30000H40 | 40 foot clear reinforced PVC for Standard Ring Vacs - 3/4" | 3/4" | $156.00 |

| 30000H50 | 50 foot clear reinforced PVC for Standard Ring Vacs - 3/4" | 3/4" | $186.00 |

| 30001H10 | 10 foot clear reinforced PVC for Standard Ring Vacs - 1" | 1" | $63.00 |

| 30001H20 | 20 foot clear reinforced PVC for Standard Ring Vacs - 1" | 1" | $100.00 |

| 30001H30 | 30 foot clear reinforced PVC for Standard Ring Vacs - 1" | 1" | $138.00 |

| 30001H40 | 40 foot clear reinforced PVC for Standard Ring Vacs - 1" | 1" | $174.00 |

| 30001H50 | 50 foot clear reinforced PVC for Standard Ring Vacs - 1" | 1" | $216.00 |

| 30002H10 | 10 foot clear reinforced PVC for Standard Ring Vacs - 1-1/4" | 1-1/4" | $67.00 |

| 30002H20 | 20 foot clear reinforced PVC for Standard Ring Vacs - 1-1/4" | 1-1/4" | $109.00 |

| 30002H30 | 30 foot clear reinforced PVC for Standard Ring Vacs - 1-1/4" | 1-1/4" | $155.00 |

| 30002H40 | 40 foot clear reinforced PVC for Standard Ring Vacs - 1-1/4" | 1-1/4" | $196.00 |

| 30002H50 | 50 foot clear reinforced PVC for Standard Ring Vacs - 1-1/4" | 1-1/4" | $234.00 |

| 30003H10 | 10 foot clear reinforced PVC for Standard Ring Vacs - 1-1/2" | 1-1/2" | $84.00 |

| 30003H20 | 20 foot clear reinforced PVC for Standard Ring Vacs - 1-1/2" | 1-1/2" | $146.00 |

| 30003H30 | 30 foot clear reinforced PVC for Standard Ring Vacs - 1-1/2" | 1-1/2" | $197.00 |

| 30003H40 | 40 foot clear reinforced PVC for Standard Ring Vacs - 1-1/2" | 1-1/2" | $257.00 |

| 30003H50 | 50 foot clear reinforced PVC for Standard Ring Vacs - 1-1/2" | 1-1/2" | $314.00 |

| 30004H10 | 10 foot clear reinforced PVC for Standard Ring Vacs - 2" | 2" | $107.00 |

| 30004H20 | 20 foot clear reinforced PVC for Standard Ring Vacs - 2" | 2" | $192.00 |

| 30004H30 | 30 foot clear reinforced PVC for Standard Ring Vacs - 2" | 2" | $273.00 |

| 30004H40 | 40 foot clear reinforced PVC for Standard Ring Vacs - 2" | 2" | $357.00 |

| 30004H50 | 50 foot clear reinforced PVC for Standard Ring Vacs - 2" | 2" | $441.00 |

| More Information or Buy Here |

| Hose Clamps For Ring Vac Hose | |||

|---|---|---|---|

| PART NO. | DESCRIPTION | SIZE | PRICE US DOLLARS |

| 39999CLMP | Hose clamp for 1/2" hose - 304 stainless | 9/16" inch to 1" | $5.00 |

| 30000CLMP | Hose clamp for 3/4" hose - 304 stainless | 11/16" inch to 1-1/4" | $5.20 |

| 30001CLMP | Hose clamp for 1" hose - 304 stainless | 13/16" inch to 1-1/2" | $4.30 |

| 30002CLMP | Hose clamp for 1-1/4" hose - 304 stainless | 13/16" inch to 1-3/4" | $5.50 |

| 30003CLMP | Hose clamp for 1-1/2" hose - 304 stainless | 1-1/16" inch to 2" | $5.70 |

| 30004CLMP | Hose clamp for 2" hose - 304 stainless | 1-9/16" inch to 2-1/2" | $6.00 |

| More Information or Buy Here |

- Overview

-

Product Overview

316L Stainless Steel Ring Vac with Sanitary FlangeThe Nex Flow® Ring-Vac® Pneumatic Conveying System with Sanitary Flanges are made especially for food, pharmaceutical, and other sanitary applications. All units are made from 316L stainless in sizes of 1″ to 3″.

Many applications in a sanitary environment require transport of materials over long distances. The Ring-Vac® with Sanitary Flanges have been designed for these special and demanding applications.

All Ring-Vac® products are compact,lightweight, easy to install, and portable. The compressed air supply in sanitary environments must be properly filtered to keep the compressed air clean and dry. Special filtration products are available from other supplies for this purpose if necessary.

A regulator installed upstream from the unit will control the pressure supplied to the Ring-Vac® and allow for the variation in flow rate and velocity.

Material to be conveyed must be able to have some air movement around the material to draw it into the Ring-Vac® system. It has to “breathe” so that the air passes around the material to be conveyed in order for it to be picked up. Another option is to drill holes or slots into the piping (smaller than the material conveyed) to create a suction to help pick up the material. If the material is too packed together, it may need to be loosened before it can be properly picked up to be conveyed.

Applications

- Hopper loading

- Fiber tensioning

- Material conveying

- Waste/trim removal

- Chip removal

- Part transfer

- Filling operations

- Advantages

-

Features / Advantages

316L Stainless Steel Ring Vac with Sanitary Flange

- Compact

- Quiet

- No moving parts

- Fits standard hose or tube

- Aluminum or stainless steel

- High throughput capability

- Videos

-

Videos

How The Ring Vac® Works

Ring-Vac® compressed air conveying system – Compressed air enters at point (A) into a annular plenum chamber and injected into the throat of the unit though directed nozzles. These jets of compressed air create a vacuum at the inlet (C) which draws in material and accelerates it through the unit and out at (D) conveying the material over a great vertical or horizontal distance.

- Specs

-

Specifications

PART NO. DESCRIPTION Size 30003S-316L-SAN 316L Stainless Steel Ring-Vac Only with Sanitary Flange 1-1/2″ 30004S-316L-SAN 316L Stainless Steel Ring-Vac Only with Sanitary Flange 2″ 30005S-316L-SAN 316L Stainless Steel Ring-Vac Only with Sanitary Flange 2-1/2″ 30006S-316L-SAN 316L Stainless Steel Ring-Vac Only with Sanitary Flange 3″ PART NO. DESCRIPTION Size 30003HTS-316L-SAN 316L Stainless Steel Ring-Vac High temp. Only with Sanitary Flange 1-1/2″ 30004HTS-316L-SAN 316L Stainless Steel Ring-Vac High temp. Only with Sanitary Flange 2″ 30005HTS-316L-SAN 316L Stainless Steel Ring-Vac High temp. Only with Sanitary Flange 2-1/2″ 30006HTS-316L-SAN 316L Stainless Steel Ring-Vac High temp. Only with Sanitary Flange 3″ - Performance

-

Performance

MODEL Size Outside Diameter inches (mm) Air Consumption SCFM at 80 PSIG (SLPM at 5.5 BAR) Vacuum inches H2O (KPG) 30000 30000S 30000HTS 30000S-316L 30000HTS-316L 3/4″ (19mm) 11 (303) -72 (-18) 30001 30001S 30001T 30001TS 30001HTS 30001THTS 30001S-316L 30001HST-316L 1″ (25mm) 15 (415) -42 (-11) 30002 30002S 30002T 30002TS 30002SHTS 30002HTS 30002S-316L 30002HTS-316L 1 1/4 ” (32mm) 26 (730) -42 (-11) 30003TS 30003THTS 30003THTS 30003THTS 30003S-316L 30003HTS-316L 30003S-316L-SAN 30003HTS-316L-SAN 1-1/2″ (38mm) 33 (932) -39 (-9) 30004 30004S 30004T 30004TS 30004THTS 30004HTS 30004S-316L 30004HTS-316L 30004S-316L-SAN 30004HTS-316L-SAN 2″ (51mm) 45 (1270) -28 (-7) 30005 30005S 30005HTS 30005S-316L-SAN 30005HTS-316L-SAN 2 1/2″ (63.5mm) 58.5 (1655) -23.5 (-6) 30006 30006S 30006HTS 30006TS 30006THTS 30006S-316L-SAN 30006HTS-316L-SAN 3″ (76mm) 69 (1940) -14.7 (-4) - Pricing

-

316L Stainless Steel Ring Vac™ only with Sanitary Flange PART NO. DESCRIPTION SIZE PRICE US DOLLARS 30003S-316L-SAN 316L Stainless Steel Ring-Vac Only with Sanitary Flange 1-1/2″ $1,200.00 30004S-316L-SAN 316L Stainless Steel Ring-Vac Only with Sanitary Flange 2″ $1,300.00 30005S-316L-SAN 316L Stainless Steel Ring-Vac Only with Sanitary Flange 2-1/2″ $2,100.00 30006S-316L-SAN 316L Stainless Steel Ring-Vac Only with Sanitary Flange 3″ $3,300.00 More Information or Buy Here 316L Stainless Steel Ring Vac™ High temp. Only with Sanitary Flange PART NO. DESCRIPTION SIZE PRICE US DOLLARS 30003HTS-316L-SAN 316L Stainless Steel Ring-Vac High temp. Only with Sanitary Flange 1-1/2″ $1,400.00 30004HTS-316L-SAN 316L Stainless Steel Ring-Vac High temp. Only with Sanitary Flange 2″ $1,500.00 30005HTS-316L-SAN 316L Stainless Steel Ring-Vac High temp. Only with Sanitary Flange 2-1/2″ $2,300.00 30006HTS-316L-SAN 316L Stainless Steel Ring-Vac High temp. Only with Sanitary Flange 3″ $3,600.00 More Information or Buy Here

Hose for Air Operated Conveyor PART NO. DESCRIPTION SIZE PRICE US DOLLARS 39999H10 10 foot clear reinforced PVC for Standard Ring Vacs - 1/2" 1/2" $41.00 39999H20 20 foot clear reinforced PVC for Standard Ring Vacs - 1/2" 1/2" $70.00 39999H30 30 foot clear reinforced PVC for Standard Ring Vacs - 1/2" 1/2" $100.00 39999H40 40 foot clear reinforced PVC for Standard Ring Vacs - 1/2" 1/2" $126.00 39999H50 50 foot clear reinforced PVC for Standard Ring Vacs - 1/2" 1/2" $151.00 30000H10 10 foot clear reinforced PVC for Standard Ring Vacs - 3/4" 3/4" $57.00 30000H20 20 foot clear reinforced PVC for Standard Ring Vacs - 3/4' 3/4" $89.00 30000H30 30 foot clear reinforced PVC for Standard Ring Vacs - 3/4" 3/4" $123.00 30000H40 40 foot clear reinforced PVC for Standard Ring Vacs - 3/4" 3/4" $156.00 30000H50 50 foot clear reinforced PVC for Standard Ring Vacs - 3/4" 3/4" $186.00 30001H10 10 foot clear reinforced PVC for Standard Ring Vacs - 1" 1" $63.00 30001H20 20 foot clear reinforced PVC for Standard Ring Vacs - 1" 1" $100.00 30001H30 30 foot clear reinforced PVC for Standard Ring Vacs - 1" 1" $138.00 30001H40 40 foot clear reinforced PVC for Standard Ring Vacs - 1" 1" $174.00 30001H50 50 foot clear reinforced PVC for Standard Ring Vacs - 1" 1" $216.00 30002H10 10 foot clear reinforced PVC for Standard Ring Vacs - 1-1/4" 1-1/4" $67.00 30002H20 20 foot clear reinforced PVC for Standard Ring Vacs - 1-1/4" 1-1/4" $109.00 30002H30 30 foot clear reinforced PVC for Standard Ring Vacs - 1-1/4" 1-1/4" $155.00 30002H40 40 foot clear reinforced PVC for Standard Ring Vacs - 1-1/4" 1-1/4" $196.00 30002H50 50 foot clear reinforced PVC for Standard Ring Vacs - 1-1/4" 1-1/4" $234.00 30003H10 10 foot clear reinforced PVC for Standard Ring Vacs - 1-1/2" 1-1/2" $84.00 30003H20 20 foot clear reinforced PVC for Standard Ring Vacs - 1-1/2" 1-1/2" $146.00 30003H30 30 foot clear reinforced PVC for Standard Ring Vacs - 1-1/2" 1-1/2" $197.00 30003H40 40 foot clear reinforced PVC for Standard Ring Vacs - 1-1/2" 1-1/2" $257.00 30003H50 50 foot clear reinforced PVC for Standard Ring Vacs - 1-1/2" 1-1/2" $314.00 30004H10 10 foot clear reinforced PVC for Standard Ring Vacs - 2" 2" $107.00 30004H20 20 foot clear reinforced PVC for Standard Ring Vacs - 2" 2" $192.00 30004H30 30 foot clear reinforced PVC for Standard Ring Vacs - 2" 2" $273.00 30004H40 40 foot clear reinforced PVC for Standard Ring Vacs - 2" 2" $357.00 30004H50 50 foot clear reinforced PVC for Standard Ring Vacs - 2" 2" $441.00 More Information or Buy Here Hose Clamps For Ring Vac Hose PART NO. DESCRIPTION SIZE PRICE US DOLLARS 39999CLMP Hose clamp for 1/2" hose - 304 stainless 9/16" inch to 1" $5.00 30000CLMP Hose clamp for 3/4" hose - 304 stainless 11/16" inch to 1-1/4" $5.20 30001CLMP Hose clamp for 1" hose - 304 stainless 13/16" inch to 1-1/2" $4.30 30002CLMP Hose clamp for 1-1/4" hose - 304 stainless 13/16" inch to 1-3/4" $5.50 30003CLMP Hose clamp for 1-1/2" hose - 304 stainless 1-1/16" inch to 2" $5.70 30004CLMP Hose clamp for 2" hose - 304 stainless 1-9/16" inch to 2-1/2" $6.00 More Information or Buy Here