The Nex Flow Difference: Why we treat our materials differently?

Nex Flow Air Products Corp. sets itself apart from its competitors by doing a few things differently with the materials that we use in manufacturing our products. While some producers are actually quite similar in product as to how they deal with material, we stand out in four specific areas as to what we do with the materials of manufacture. Differences for Nex Flow are as follows:

- Anodized aluminum parts

- Powder coated parts

- No Plastic in our vortex tubes

- We do not mix aluminum and stainless steel in our vortex tube packages

Anodized Aluminum parts

We make it a point to anodize our aluminum air knives, amplifier, air jets, air wipes and air operated conveyors.

It is actually much easier (and certainly less costly) to produce these items without anodizing due to the importance of efficient aerodynamic design. When the products are anodized the surface changes, even if the change is very small, it makes it more difficult to keep a flat part flat (i.e. air knives). But, we CAN do and we do it because of the value the anodizing adds benefits to the products.

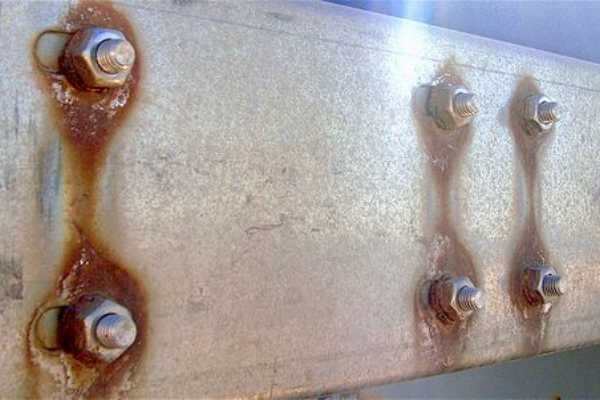

Anodizing helps guard against the effects of the factory environment on the aluminum. Unprotected aluminum will form a powdering while oxide over time. Anodizing keeps the product looking better and longer even when using dissimilar metals in assembly, stainless shims, stainless screws, with aluminum bodies, it protects the accessories from even minor effects of cathodic corrosion.

Cathodic corrosion can occur in a highly humid environment or if the parts get wet. Dissimilar metals can act like a battery where the more active metal can corrode unless there is some form of protection. You can see this effect, for example, with rust around screws used on some buildings or machines because the screws are of one material while the metal it is screwed into is another. When paint wears away, it leaves unprotected metal that is more electrically “active” than the metal in the screw. By anodizing and protecting our product, Nex Flow ensures that our accessories will last longer and look better over time.

Powder Coated parts

Some of our cast zinc parts, specifically our Air Edger flat jet nozzles and cast Fixed X-Stream Air Amplifier, also have powder coating. It provides a much better finish and look to the product and again, extra layer of protection from the factory environment. Powder coating is an excellent protection in a factory environment. Powder coating parts adds intrinsic value to the products to the betterment of the customer providing a product that is longer lasting look better through time.

No Plastic in Vortex Tubes

Most manufacturers of vortex tubes use injection molded plastic “generators” which are used in the unit to initiate the compressed air spinning effect. Nex Flow machines their “brass” generators for that purpose instead of plastic. While plastic would be much less costly, brass offers a few advantages. Injection molding plastic will have some variations in production, especially as the mold wears out. By machining the metal generators we have much greater consistency with the parts which translates into much greater consistency in performance from one vortex tube to the next. Vortex tubes consist of several parts and of course, each part has a certain tolerance in manufacturing. Nex Flow has very tight tolerances on each part and the generators especially require very tight tolerances. The more pieces involved in assembling a part, the more the cumulative effect on the overall variation in tolerance and therefore performance since the operation of all Nex Flow products are based on aerodynamic shapes.

As the generator is such a critical component in a vortex tube, we recognize the need to use metal instead of plastic. Another advantage of using metal, in our case brass, instead of plastic is that plastic can possibly crack over time. If the compressed air supply is dirty the generator can also build up dirt and engrain itself, hence requiring replacement. The metal ones we use are easily cleaned. Sometimes vortex tubes or their packaged versions are used in very hot environments so the parts must be able to hold up in high temperature areas, especially when not operating. In these cases even competitive units replace their plastic generator with metal. Nex Flow vortex tubes and many of their packages are therefore more flexible in the environments where they can be used. While competitors would charge extra for a special product, our standard product can generally be used instead.

We do not mix Aluminum and Stainless Steel

Our vortex tube packages include tool coolers, mini coolers, adjustable coolers, panel coolers, etc. Of particular importance is the materials used in a panel cooler used for cabinet enclosure cooling and camera cooling. Many manufacturers will use a stainless steel vortex tube packages as a control panel cooler using aluminum housing and attachments. While not a problem in relatively benevolent factory environments, it can become an issue in very humid area or in applications where they are used in wash down conditions. Cathodic corrosion can occur described earlier with dissimilar metals with air knives. On one visit to a customer there was actually a competitive vortex tube cooling system with a big hole on the side of the assembly. Cabinet cooling applications are very critical because you do not want any possibility for moisture getting into the control panel. This is the reason vortex coolers should have the proper approvals to insure this does not happen (such as Underwriters Laboratory testing and approval).

Cabinet Coolers are essentially vortex tubes with a cover and some system to prevent moisture from getting inside of the cover and possibly then into the cabinet. This cover was aluminum and the vortex tube another material. The environment was a relatively wet environment, so over time cathodic corrosion cause the aluminum to corrode and create a hole in the protective cover. Thus, creating a potential risk for water to get into the electrical cabinet. It is for this very reason (preventing cathodic corrosion) that Nex Flow only has stainless steel covers for their stainless steel vortex tubes.

Similarly with all other packages systems, whether they are tool coolers or adjustable coolers, the packages are made with stainless steel only and not a mixture of stainless steel and aluminum.

It’s a Wrap

These are some of the reasons why Nex Flow treats their materials differently. While some of these “differences” in material handling and treatment can be more costly from a manufacturing point of view, they do offer significant added value to the products and a benefit to the customer, and still with a very competitive price.